China’s Laser “Wonder Machine” Tops the Globe: Welding an Entire Vehicle in 43 Seconds

Guess how long it takes to weld an entire new energy vehicle (NEV)? The answer may come as a huge surprise—43 seconds! So, how did China’s laser technology break the foreign monopoly? Most people are familiar with lasers: their high energy density makes them ideal for cutting materials, and welding and cutting are inherently linked.

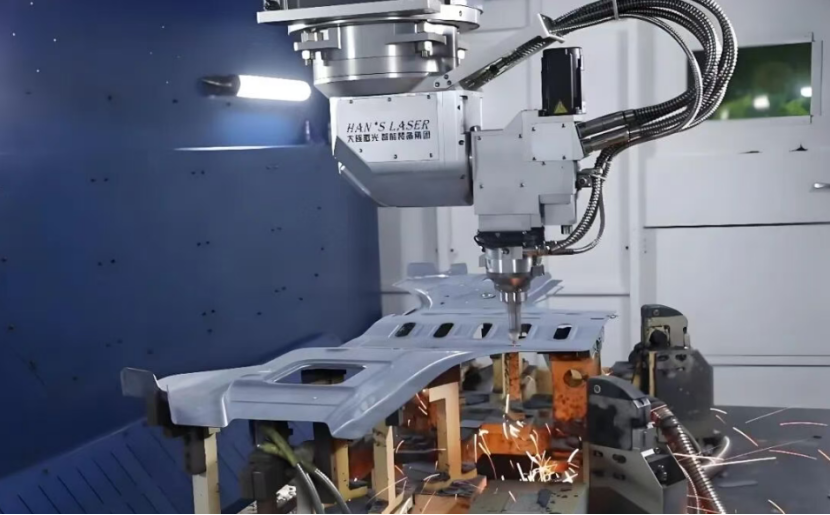

Let’s start with 3D five-axis laser cutting technology. As an industrial processing system for metal parts, it uses a “five-axis linkage system” to enable flexible multi-angle movement of workpieces. At the same time, it focuses energy with a high-power laser beam to quickly melt workpieces, combined with intelligent programming and real-time trajectory correction. This system can precisely cut metal parts with complex 3D curved surfaces, achieving extremely high processing accuracy.

Software is certainly crucial too. A specially developed numerical control (NC) system controls parameters such as the movement trajectory, speed, acceleration of the laser cutting head, and laser power, enabling precise cutting of complex 3D parts. Boasting superior performance, 3D five-axis laser cutting machines are widely used in multiple manufacturing fields.

Take the processing of hot-formed components in the automotive industry, for example. These machines can cut high-strength steel plates—such as drilling holes and trimming high-strength steel parts like door anti-collision beams, chassis components, and engine parts—and perfectly replace die stamping.

Another application is component processing in the aerospace sector. 3D five-axis laser cutting technology is used to manufacture aircraft engine blades, wings, fuselage structural parts, and spacecraft components. It precisely cuts complex curved surfaces and thin-walled structures, not only ensuring the dimensional accuracy and surface integrity of parts but also helping reduce aircraft weight, improve fuel efficiency, and enhance flight performance.

Additionally, this technology is widely applied in shipbuilding, construction machinery, medical equipment, architectural decoration, electronics, and electrical appliances, providing strong support for technological innovation and product upgrading in these industries.

Through independent R&D, China’s Huazhong Numerical Control successfully launched the “Huazhong-9 Intelligent NC System”—a domestically produced high-performance NC system. This system has four core functions: autonomous perception, autonomous learning, autonomous decision-making, and autonomous execution. It surpasses imported systems in processing efficiency and stability, with its processing efficiency reaching 105% of that of imported systems.

High-power fiber laser generators are regarded as the “heart” of laser cutting, as they stably produce laser beams. China’s independently developed high-power fiber laser generators, with power ranging from 3kW to 20kW, have completely broken foreign monopolies, and their cost is only 60% of that of imported ones.

The cutting head, seen as the “sharp blade,” is a key component that directly interacts with workpieces. Once, due to its complex structure and high sealing requirements, it relied entirely on imports from Germany’s Trumpf. However, HG Tech’s globally launched fifth-generation intelligent 3D five-axis laser cutting machine has achieved 100% independent control over key core components. It not only breaks the technological blockade of high-end laser cutting equipment but also advances the process of domestic substitution.

Today, China has successfully joined Germany, Italy, and Japan as the fourth country in the world to fully master independent 3D five-axis laser processing technology. Chinese enterprises have also entered the international market competition for high-end laser equipment. In terms of equipment origin: Europe, relying on the solid accumulation of German and Italian enterprises, accounts for 42% of global production output, ranking first; followed by China, which has broken the monopoly and caught up with its world-leading industrial manufacturing system, accounting for 38%; Japan, known for its high-tech industries, ranks third with a production share of approximately 15%.

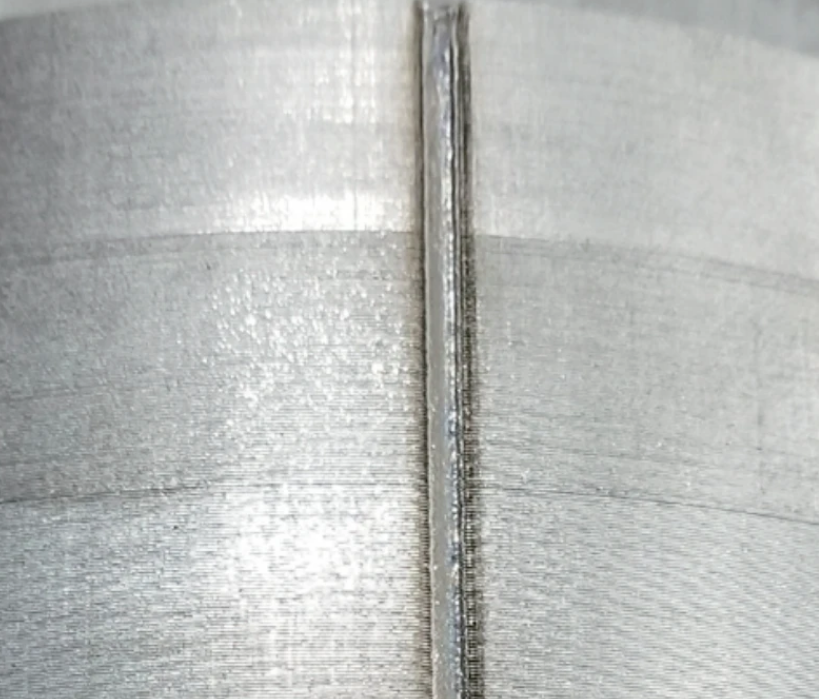

As laser cutting breaks the monopoly, China’s laser welding technology has also reached the international advanced level. It has achieved remarkable results especially in the fields of medium-thick plate welding, handheld laser welding, and ultra-fast laser welding. Today, China has the technology and capability to form complex titanium alloy components larger than 12 square meters using lasers, which have been applied in the prototype and product manufacturing of multiple domestic aerospace R&D projects.

Lasers have high energy and produce significant thermal effects when interacting with solid materials. Laser cleaning, in particular, has the advantages of high efficiency, high cleanliness, large coverage, and the ability to operate at a distance safely and reliably.

After years of R&D and exploration, China has achieved a leap in 3D five-axis laser cutting technology from “being controlled by others” to “independent control.” Behind this lies not only the technological breakthroughs of China’s high-tech enterprises but also the strong demand from its industrial system.

On the one hand, as the world’s largest manufacturing country, China’s urgent need for high-end and intelligent transformation constitutes the most powerful market driving force. The strict requirements for processing complex curved parts in the aerospace field, the demand for large-scale production of lightweight battery trays in the NEV industry, and the expectation for efficiency upgrades in the cutting of special-shaped curved surfaces in shipbuilding have jointly formed the “rigid demand scenarios” for technological iteration.

On the other hand, Chinese laser equipment enterprises represented by HG Tech and Han’s Laser have overcome core technologies with the perseverance of “polishing a sword for ten years.” This positive interaction of “the market raises questions, and enterprises take on the tasks” has allowed technological innovation to truly take root in the industrial soil.

In the future, China’s major technological equipment will continue to make new breakthroughs!

Post time: Oct-14-2025