Encyclopedia of Welding Knowledge: A Brief Discussion on the Classification

and Welding Processes of Laser Welding

- Classification by laser output energy mode:

- Continuous laser welding: A continuous and uninterrupted weld shape is formed during the welding process.

- Pulsed laser welding: Since the energy input to the surface of the welded part is intermittent, each pulsed light spot acts on the surface of the welded workpiece to form a circular weld spot. Different weld shapes can be obtained according to different laser parameters.

- Classification by the power density of the focused laser spot:

- Laser heat conduction welding: The power density is relatively low, generally less than 10⁵ W/cm². The laser transmits energy to the surface of the welded workpiece, heating the metal surface to a temperature between the melting point and boiling point. Heat is transferred to the interior of the metal through heat conduction to form a weld, which is similar to tungsten inert gas (TIG) welding.

- Laser deep penetration welding (keyhole welding): When the laser power density acting on the metal surface is greater than 10⁵ W/cm², the high-power laser beam acts on the surface of the metal material, causing local melting and forming a “keyhole”. The laser beam penetrates into the interior of the molten pool through the “keyhole” to form a weld.

- Classification by control mode:

- Manual laser welding machine

- Automatic laser welding machine

- Galvo laser welding machine

- Classification by laser type:

- YAG laser welding machine

- Semiconductor laser welding machine

- Fiber laser welding machine

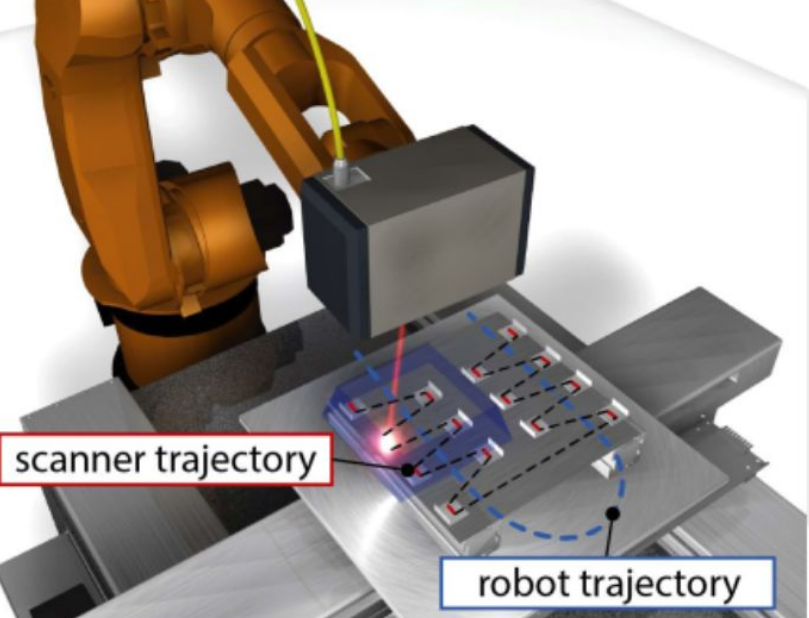

1. Flying Laser Welding

Main Applications:

★ Advantages:

- Compatible with any weld form

- Suitable for any weld direction

- User-defined weld/spot distribution

- Optimized stress distribution

- Capable of high-speed spot welding, seam welding, lap welding, butt welding, fillet welding, and overlap welding

- Real-time synchronization between the welding head and the robot to accelerate the laser welding process

- Smaller floor space requirement

- Lower maintenance and logistics costs

2. Spiral Laser Welding

Main Applications:

★ Advantages:

- Wider weld

- Extremely high processing repeatability/process stability

- Better weld formation

- Simpler post-processing and smoother surface of the welded workpiece

- Excellent aluminum alloy welding capability

3. Laser Brazing

Main Applications:

★ Advantages:

- Reduces defects of pure laser welding, such as pores, cracks, and excessive fitting gaps of products

- Improves weld strength and obtains a perfect weld bead

- Only the brazing filler metal melts during brazing, while the base metal does not

- Small deformation of brazed joints, smooth and aesthetic appearance, suitable for welding precision, complex components made of different materials

- Small heat-affected zone and high compressive strength

4. Laser Wire-Filled Welding

Main Applications:

★ Advantages:

- Reduces defects of pure laser welding, such as pores and cracks

- Improves the qualification rate of welded products and allows slightly larger gaps between welded products

- The base metal melts during welding, and the weld strength is higher than that of the base metal

5. Oscillating Brazing

Main Applications:

★ Advantages:

- Weld tracking to determine the weld trajectory of the workpiece in real time

- Adaptive adjustment of the welding trajectory in the XYZ three directions according to different workpiece deviations to obtain good welding quality

- Improves the consistency rate of product welding

6. Three-Spot Brazing

Main Applications:

★ Advantages:

- More stable and reliable brazing process

- Faster speed

- Higher strength

- Better appearance quality of hot-dip galvanized sheet welds

- On-line cleaning process

- Dynamic energy adjustment

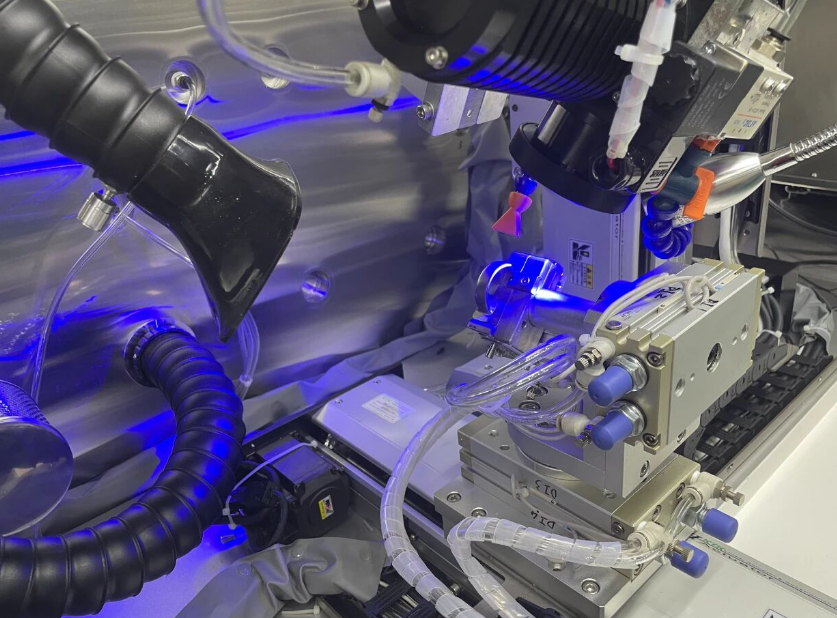

7. Multi-Wavelength Hybrid Welding

★ Advantages:

- Reduces the content of pores

- Enhances the stability of the welding bead and increases the welding efficiency

- Effectively relieves thermal stress, reduces cracks, improves weld strength, and obtains weld beads with a relatively uniform appearance

In conclusion, currently, in the laser industry as a whole, foreign technologies and equipment still take the leading position. They are comprehensively advanced in all aspects, from laser hosts and optical processing heads to auxiliary equipment such as chillers, power meters, in-welding monitoring, post-welding inspection, and TCP calibrators. Domestic enterprises are making every effort to catch up. However, in the field of laser welding applications, China has become relatively close to the international advanced level, with a number of high-quality enterprises emerging and achieving excellent results.

Post time: Sep-05-2025