From June 17th to 20th, the 28th Essen Welding & Cutting Fair (hereinafter referred to as “Essen Fair”) was held at the Shanghai New International Expo Center. This exhibition focuses on the cutting-edge technologies and innovative achievements in the welding industry, attracting a large number of domestic and foreign customers as well as professionals to visit. Mavenlaser showcased a series of cutting-edge intelligent products and solutions in a dazzling manner.

The core of intelligent manufacturing, with a heavyweight product matrix making its debut

At this exhibition, the company showcases six core products that lead industry transformation in a concentrated manner:

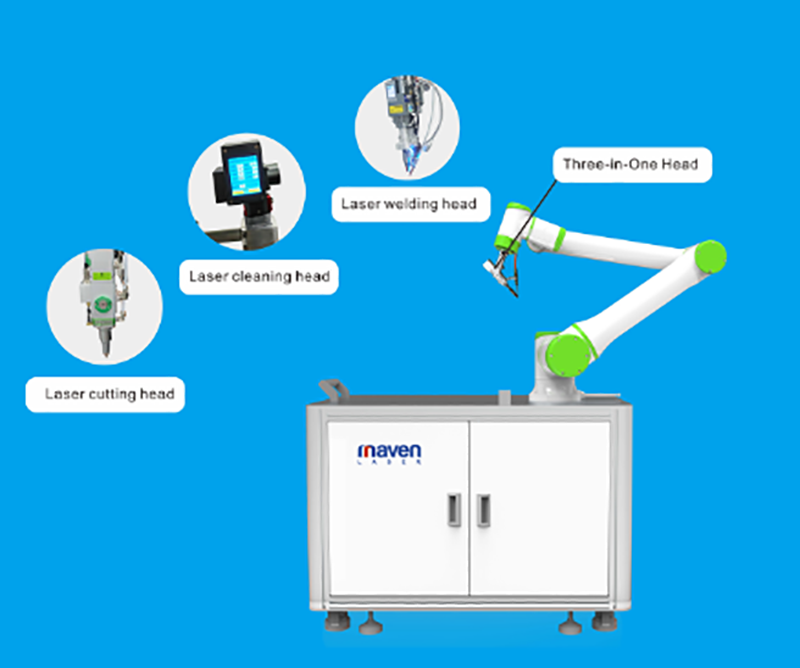

Collaborative robot laser welding/cutting/cleaning workstation: Breaking the safety fence restrictions, human-machine collaborative work is more flexible and safer, unlocking the application potential in complex scenarios.

— Maven has developed its own remote control, which is convenient for precise adjustment.

— It supports collaborative wire feeding, automatic wire breakage, and anti-sticking wire.

— It supports laser waveform control.

— The self-developed system monitors the working status of each component, and the machine gives real-time alerts.

— It has independently developed a mini welding head (1.9kg), which supports welding at various angles.

High-performance robot laser cutting system: Deeply integrating precision robots with high-power laser technology, it meets the strict requirements for efficient and high-quality cutting of metal plates.

Application :Sheet metal processing industry, machinery manufacturing industry, military industry, aerospace industry, medical device industry, agricultural machinery industry, automotive manufacturing industry, construction machinery industry, loader industry, kitchenware manufacturing industry, air conditioning industry, hardware appliances industry, shipbuilding industry, tram industry, new energy industry, advertising production industry, outdoor decoration industry, decoration industry, iron processing and other industries.

Smart Portable All-in-One Mini Fiber Laser Welding Machine: Revolutionary design frees your hands, making it easy to handle various scenarios and efficient welding of different products.

24-hour continuous light output test

Laser Brands : Max, Raycus,GW,IPG

Support brand OEM and ODM customization

Application :Welding of products in industries such as household hardware, kitchenware and bathroom fixtures, stainless steel door handles, electronic components, sensors, watches, precision machinery, communications, handicrafts, and high-strength industries such as automotive hydraulic tongs.

Laser-Arc Hybrid Welding Scheme:

— High welding efficiency

— Can weld complex products

— It causes little loss of processing materials

— It can process different materials and shapes

Application :It is mainly applied in heavy industry welding fields such as mechanical manufacturing, automobiles and auto parts, construction machinery, structural steel beams, ships, Bridges, etc.

Since the opening of the exhibition, the maven technical team has conducted multiple product demonstrations and technical explanations for the audience. In the dynamic display area of the robot-free teaching system, visitors stopped to watch one after another. Many of them took out their mobile phones to record the entire process of automated welding. In the interactive experience area of the zero pre-weld seam tracker, almost every visiting customer showed great interest, and many customers expressed their purchase intentions on the spot.

During the exhibition, domestic and foreign automation integrators, equipment manufacturers and end users all expressed high recognition of maven products. Multiple intention cooperation agreements were reached on the spot, further confirming maven’s technical strength and industry influence in the field of intelligent welding.

Post time: Jun-20-2025