In modern automated welding technology, industrial welding robots have emerged as a solution thanks to their efficient operational mechanism. With the continuous advancement of science and technology, we have identified issues with traditional manual welding, such as low efficiency and inconsistent quality. To meet the demands for high-volume, high-quality welding, industrial welding robots have come into being.

The Operational Mechanism of Industrial Welding Robots

The operational mechanism of industrial welding robots can be simply divided into three steps: perception, decision-making, and execution.

- Perception: The robot acquires environmental and workpiece information using sensors. Through laser or vision sensors, it can accurately detect welding-related data such as the position and shape of welding joints.

- Decision-Making: Based on the perceived data, the robot makes decisions. It determines the welding path and speed according to pre-programmed algorithms and parameters, and adjusts welding parameters based on the size and shape of the workpiece to ensure welding quality and stability. This process relies on high-performance computer systems for complex calculations and analysis.

- Execution: Guided by the decisions, the robot begins the welding operation. It uses tools such as welding torches or laser welding heads to perform welding along the preset path and speed. The robot’s mechanical arm is capable of free movement, allowing flexible adjustment of the welding position and angle. To ensure welding accuracy and consistency, the robot continuously controls and adjusts based on real-time feedback from sensors.

Industrial welding robots achieve automated welding operations through their perception-decision-execution mechanism. Their emergence has brought about drastic changes in industrial production, improving production efficiency, welding quality, and workplace safety. With further technological development, industrial welding robots will be applied in more fields, making greater contributions to the development of various industries.

Targeting Niche Markets: A Core Strategy for Robot Enterprises to Navigate Uncertain Cycles

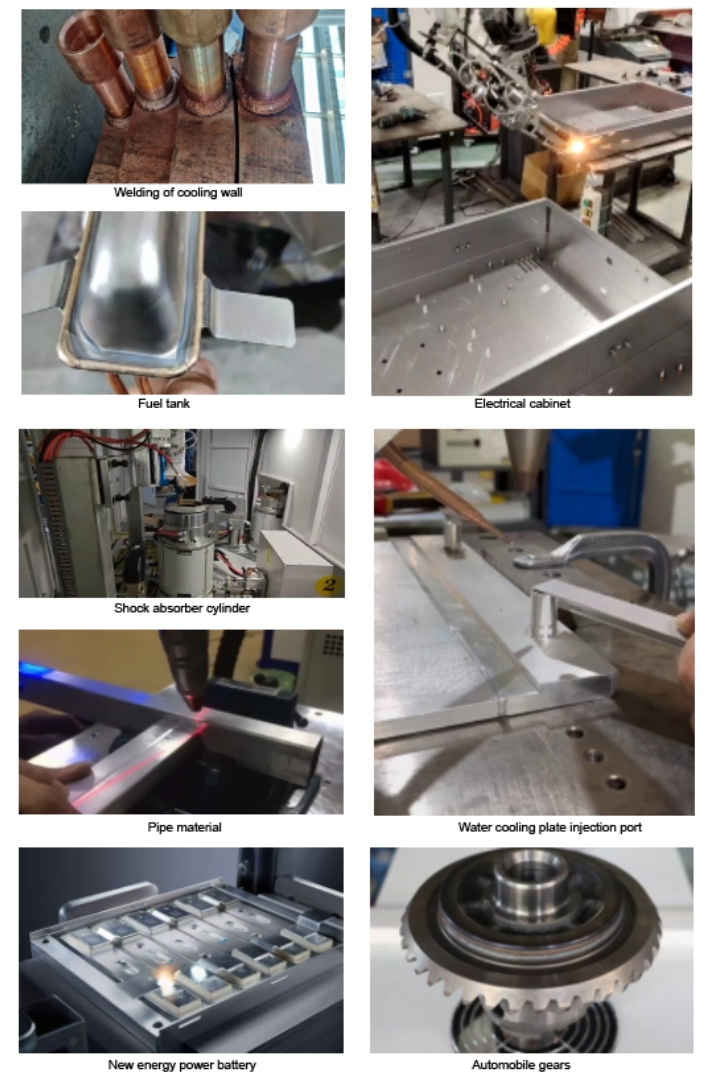

From loading/unloading and material handling & palletizing, to gluing, screw fastening, and assembly, and further to welding and spraying—whether it is industrial robot enterprises or collaborative robot enterprises, all are demonstrating their determination and actions to deeply cultivate niche markets.

However, in terms of penetration rate, as high-end processes, welding and spraying still have relatively low penetration rates for collaborative robots. This indicates that the overall technical level of the industry has not yet reached the ideal optimal state.

If we use a river as a metaphor, most enterprises are still in the “shallow waters” of welding and spraying. The “deep waters,” with turbulent currents and numerous hidden reefs, represent higher technical thresholds and greater challenges.

Welding: The “Industrial Sewing Machine” and the New Opportunity for Collaborative Robots

Welding is known as the “industrial sewing machine” and is a ubiquitous demand in industrial production. After years of development, the standardized application of industrial robots in welding operations has become relatively mature. However, with the rising demand for welding of small-batch, multi-variety, and large-size products in industries such as steel structures and shipbuilding, collaborative robots have found new “arenas,” and numerous players are competing for market share in the welding field.

“From the perspective of welding processes, the two main types widely used in the market currently are arc welding and laser welding. Among them, arc welding places much higher requirements on collaborative robots in terms of body stability, anti-vibration performance, trajectory accuracy, and working cycle than loading/unloading operations. For laser welding applications, the requirements for the robot arm are even higher, especially in thin-plate welding.”

[Certain collaborative robot solutions] meet the requirements of high quality, high reliability, high safety, and traceability, and feature fast speed, stability, and high trajectory accuracy. They have been deployed in bulk and stably in multiple well-known enterprises, including Xiaomi Eco-chain companies, as well as automakers such as GM, Hongqi, XPeng, SAIC, and Li Auto, and CRRC.

Limitations of Traditional Welding Technologies and the Shift to New Methods

For many years, manufacturers across the industry have been using traditional welding technologies such as MIG (Metal Inert Gas) welding or TIG (Tungsten Inert Gas) welding. However, these traditional technologies have inherent limitations:

- TIG welding is a time-consuming, two-handed welding method that requires experienced and skilled operators. It generates extremely high heat, which deforms thin materials; it is difficult to weld copper; and it is limited when welding metals of different thicknesses.

- MIG welding requires consumable welding wires, pre-welding material cleaning, and beveled joints to achieve full penetration welding on thick materials. Its travel range and working angle are limited, and vertical-position welding can be challenging.

As the industry continues to evolve, manufacturers are seeking new ways to remain competitive. They have realized that this requires reducing costs, improving efficiency, and ensuring repeatable part quality. Another emerging challenge is enabling new welders to quickly improve productivity without sacrificing quality.

This is why more and more manufacturers are turning to newer welding methods, such as handheld laser welding. Compared with MIG and TIG welding, handheld laser welding can increase welding speed by up to four times, thereby enhancing productivity and precision.

Technical Features of Intelligent Laser Welding Equipment

- High-Precision Welding: Intelligent laser welding equipment uses a high-energy-density laser beam as the heat source, enabling micron-level welding precision to meet the welding needs of high-precision components.

- High-Efficiency Welding: Laser welding offers fast speed and a small heat-affected zone, which significantly improves production efficiency and reduces production costs.

- High Automation Level: Equipped with advanced control systems and sensors, the intelligent equipment can realize automated monitoring and adjustment of the welding process, reducing manual intervention and improving the stability of welding quality.

- Strong Flexibility: Intelligent laser welding equipment can flexibly adjust welding parameters and processes according to different welding requirements, adapting to the welding of various materials.

- Intelligent Management: By integrating technologies such as the Internet of Things (IoT) and big data, it enables remote monitoring, fault diagnosis, and predictive maintenance of welding equipment, improving the equipment’s operational efficiency and reliability.

Post time: Sep-27-2025