Jewelry Laser Cutting Machine: Leading Industry Transformation and Ushering in a New Era of Luxury Manufacturing

In the jewelry industry, where the pursuit of ultimate craftsmanship and personalized design reigns supreme, a wave of technological innovation is surging. Currently, an extremely innovative jewelry laser cutting machine has emerged, bringing unprecedented transformation to the entire industry and completely rewriting the rules of jewelry manufacturing.

This advanced jewelry laser cutting machine has become an indispensable tool for jewelry craftsmen, thanks to its outstanding cutting precision. It can achieve an impressive positioning accuracy of ±0.01mm, which means when cutting delicate components such as thin necklace chains and tiny gem setting bases, it can ensure precise dimensions without any deviation. This greatly enhances the overall quality and exquisiteness of jewelry, making each piece as flawless as a work of art.

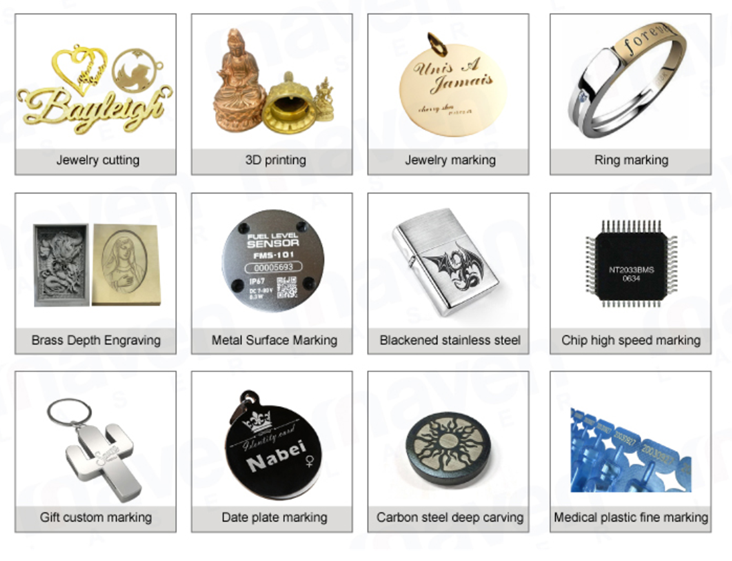

Compared with traditional cutting processes, the jewelry laser cutting machine demonstrates unparalleled advantages in cutting complex patterns and shapes. Through digital programming, it can easily interpret the bold and imaginative ideas of designers—whether it is exquisite lace patterns or unique geometric hollowed-out designs, all can be accurately cut and perfectly presented. This high level of flexibility and precision not only provides designers with a broad creative space to turn their whimsical ideas into reality but also makes customized jewelry production more efficient and convenient, satisfying consumers’ strong desire for one-of-a-kind jewelry

Efficiency improvement is another highlight of this equipment. In the fast-paced modern business environment, time is equivalent to money. With its fast cutting speed, the jewelry laser cutting machine significantly shortens the production cycle. Cutting work that originally took hours or even days can now be completed in just tens of minutes with this advanced equipment, greatly improving the production efficiency of enterprises and enhancing their market competitiveness. Taking the mass production of simple metal pendants as an example, traditional processes may take several hours, while the laser cutting machine only requires about half an hour— the efficiency improvement is obvious.

The jewelry laser cutting machine also performs exceptionally well in terms of material utilization. Its extremely narrow cutting seam effectively reduces material waste. This advantage is particularly important for expensive precious metals such as gold and platinum. Each cutting process can be precisely controlled to maximize material retention, reduce production costs, and create higher economic benefits for enterprises. According to actual calculations, after using the jewelry laser cutting machine, material utilization can be increased by 10% – 20%, which will save enterprises a considerable amount of costs in the long run.

Many well-known jewelry brands have taken the lead in introducing this jewelry laser cutting machine and achieved remarkable results. After adopting this equipment, an international first-tier jewelry brand increased its new product launch speed by 30%, reduced the product defect rate to less than 1%, significantly improved consumer satisfaction with product craftsmanship, and achieved a 20% sales growth within half a year. Additionally, a niche brand focusing on customized jewelry, with the help of the laser cutting machine, can quickly respond to customers’ personalized needs, achieving a 50% growth in orders within one year and successfully standing out in the fiercely competitive market.

With the continuous advancement and innovation of science and technology, the jewelry laser cutting machine has a bright future for development. In the future, it will continue to evolve towards c For instance, it may integrate artificial intelligence technology to realize automatic recognition of design patterns and optimization of cutting paths, further improving cutting efficiency and quality; in terms of adaptability to cutting materials, it will also continue to expand, enabling it to process more types of new jewelry materials. It is foreseeable that with the support of the jewelry laser cutting machine, the jewelry industry will embrace a more brilliant future and bring consumers more exquisite and unique jewelry works.

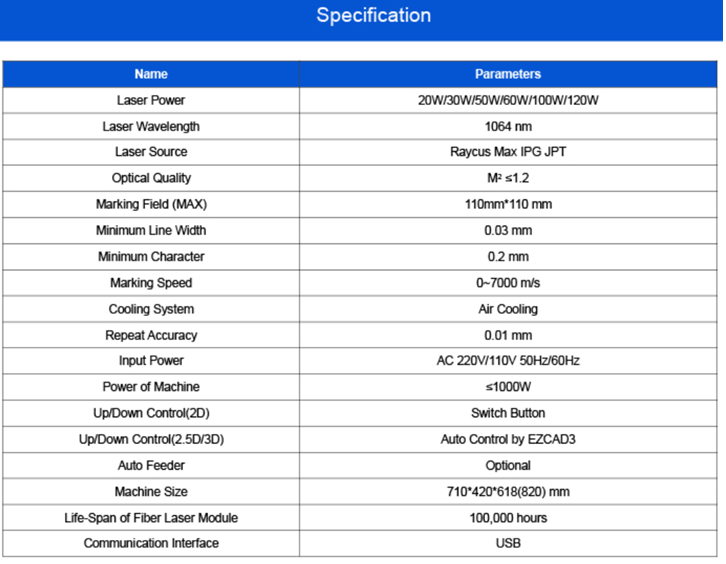

Laser Cutting Machine (Mainstream Equipment)

- Principle: It uses a high-energy-density laser beam (mostly fiber laser or CO₂ laser) to focus on the metal surface, instantly melting or vaporizing the metal material. Cooperated with a numerical control system to control the cutting path, it achieves precise cutting.

- Advantages: Non-contact processing, no mechanical pressure, avoiding metal deformation; smooth and flat cutting edges (with a roughness of up to Ra0.8μm or below), no need for subsequent polishing; extremely high precision (positioning accuracy of ±0.01mm), capable of cutting complex patterns (such as hollowed-out ring settings and patterned components).

- Applications: Cutting of metal blanks (e.g., cutting gold bars into sizes required for ring settings), cutting of complex shapes (e.g., pendant outlines and earring brackets).

Core Technical Features (Differences from Industrial Cutting Machines)

- Ultra-high precision requirement: Jewelry components are usually small in size (e.g., ear studs with a diameter of 2-5mm, gem facets with a side length of 0.5-2mm), so the positioning accuracy of the cutting machine needs to reach ±0.005-0.01mm, which is much higher than that of industrial equipment (±0.05mm).

- Low-damage processing:Low-power adaptation: Jewelry cutting does not require the high power of industrial equipment (e.g., industrial laser power ranges from 500W to 2000W). The laser power for precious metal cutting is mostly 20-100W, and the laser power for gem cutting is 5-30W, to avoid excessive material vaporization.

- Precious metals need to avoid deformation caused by mechanical pressure, so non-contact laser cutting is mostly used;

- Gems need to avoid “thermal cracking” caused by high temperatures, so they must be equipped with a water cooling system (cooling rate > 50℃/s) or cold laser technology.

- Visual operation: Some high-end equipment is equipped with a microscopic imaging system (magnification of 10-50 times) to observe the cutting process in real time, ensuring the accuracy of patterns or facets.

Post time: Sep-22-2025