Joining Hands with Partners to Redefine the Future of Intelligent Welding

Recently, the 28th Beijing Essen Welding & Cutting Fair (referred to as “Essen Fair”) was successfully held in Shanghai. Maven Automation presented cutting-edge intelligent solutions in the metal processing field to professional visitors.

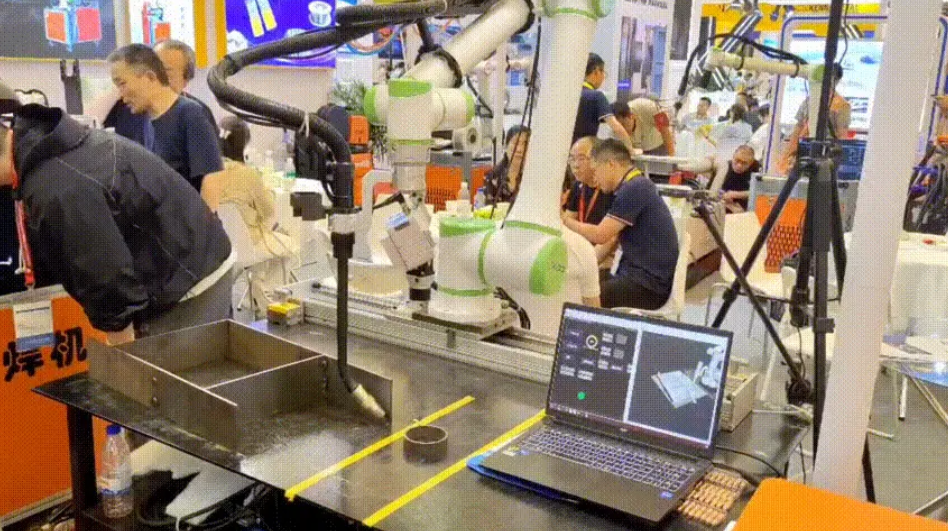

3D Vision Programming-Free Welding Robot

By deeply integrating a high-precision 3D vision system with a collaborative robot, this solution can quickly scan the 3D contour of workpieces and automatically generate the optimal welding path, without the need for complex programming. Through visual tracking and force control algorithms, the robot can accurately locate weld seams and support switching between multiple scenarios such as flat welding, vertical welding, and fillet welding. With a repeat positioning accuracy of ±0.02mm, the robot ensures uniform and aesthetic weld seams.

Mobile Welding Robot

It overcomes the problems of traditional welding robots, such as “single function, complex integration and debugging, and poor trajectory accuracy”. The “Jinghanshi” mobile welding robot can download welding processes from the cloud with one click after device networking, allowing operation without welding experience. Equipped with a full-Chinese operation interface APP, operators only need to simply select process recipes, click buttons, and drag to align points to complete welding tasks for “carbon steel, stainless steel, iron, and metal alloys”.

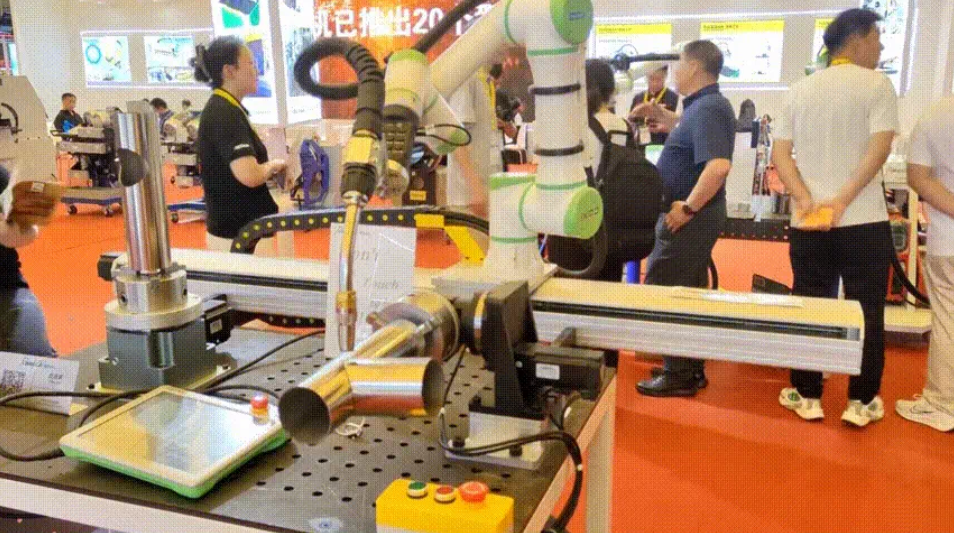

8-Axis Synchronized Welding Robot

The collaborative robot controls a 2-axis L-shaped positioner through EtherCAT communication. It realizes the welding of spatial special-shaped weld seams via 8-axis synchronization, reducing the impact of multiple clamping on weld seam accuracy and appearance. Combined with a laser positioning tracker, it solves the problems of weld seam deviation and poor workpiece consistency, thereby lowering requirements for previous processes, reducing the technical threshold of automated welding, and improving production efficiency.

Laser Welding Robot

The laser welding robot deeply integrates a high-power laser with an intelligent welding system to create an efficient and precise flexible welding solution. It supports real-time laser vision weld seam tracking, drag teaching programming, and cloud-based calling of multiple process parameters, featuring convenient operation and stable welding quality. Its modular design adapts to the needs of multiple industries and can be widely used in automotive parts, 3C electronics, precision hardware, new energy batteries and other fields.

Laser Cleaning Robot

This solution integrates a collaborative robot with laser cleaning technology. It uses the high energy density of laser to accurately remove attachments such as oxide layers, oil stains, and coatings on metal surfaces, with no grinding, no consumables, and no damage to the base material. The flexible human-machine collaborative operation makes it suitable for scenarios such as metal processing and mold surface cleaning. With an efficient and environmentally friendly cleaning method, it helps realize the intelligent upgrading of industrial cleaning processes.

Laser Cutting Robot

The laser cutting robot deeply integrates high-power laser cutting technology with a collaborative robot, featuring high-precision and multi-angle flexible cutting capabilities, and can adapt to the complex curved surface processing of metals, non-metals and other materials. The equipment supports drag programming and visual guidance, with simple operation and smooth, burr-free cutting sections, helping enterprises achieve efficient automated production.

Driven by the “automotive intelligent components + collaborative robots” dual-engine, we deeply integrate automotive-grade control technology with process scenarios to create intelligent solutions for robot welding, cutting, and cleaning. With the characteristics of “programming-free, easy operation, and high flexibility”, we help the manufacturing industry achieve comprehensive upgrading in “cost reduction, efficiency improvement, and quality enhancement”. In the future, Intelligent Manufacturing will continue to empower industrial upgrading with innovative technologies and build a new intelligent manufacturing ecosystem together with partners!

Post time: Oct-15-2025