Laser Industry Popular Science

I. Introduction to the Laser Industry

As a representative of advanced productivity, laser technology has witnessed remarkable development over the past decade—China’s laser industry has grown from a fledgling sector to a major player, with Chinese enterprises achieving rapid expansion. Looking ahead to the next decade, China’s laser industry is poised to transition from “large-scale” to “high-quality” development.

Since the 20th century, laser has been hailed as one of humanity’s greatest inventions, following atomic energy, computers, and semiconductors. Known as the “sharpest knife,” “most accurate ruler,” “brightest light,” and “extraordinary laser,” it has revolutionized modern technology.

II. Development History of Lasers

As early as 1916, Albert Einstein described the relationship between stimulated emission and spontaneous emission of atoms, sparking speculation about using lasers to amplify light. In 1958, American scientists proposed the laser principle based on the observation that a rare earth crystal irradiated by a neon bulb emits intense, highly focused light. This principle states that when matter is excited by energy matching its inherent molecular oscillation frequency, it produces this non-divergent intense light—laser.

In 1960, American scientist Theodore generated the world’s first laser (wavelength: 0.6943 microns) by exciting a ruby crystal with a high-intensity flash lamp. This milestone marked laser’s transition from theoretical science to experimental physics. Subsequently, laser technology advanced rapidly across multiple fronts, moving from the experimental phase to practical applications and gaining widespread recognition as one of the most significant inventions of the 20th century.

Today, laser processing equipment derived from laser technology has become an indispensable tool in daily industrial production, spanning sectors such as military industry, aerospace, automotive manufacturing, medical care, electronics manufacturing, and photovoltaic production.

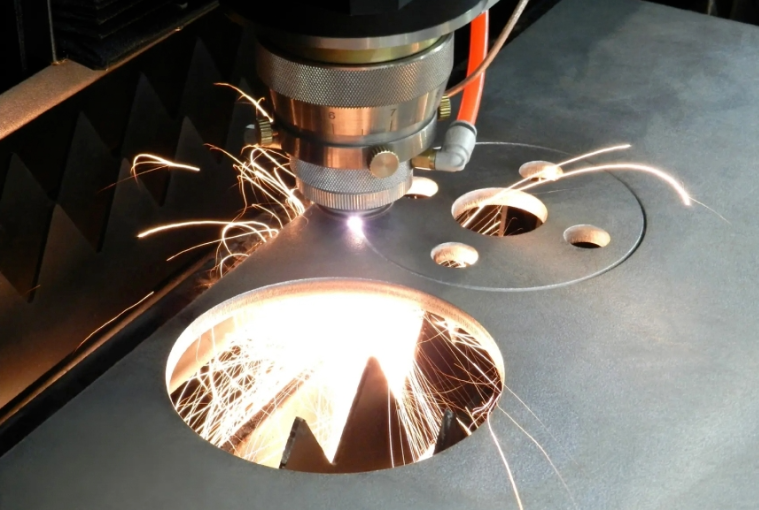

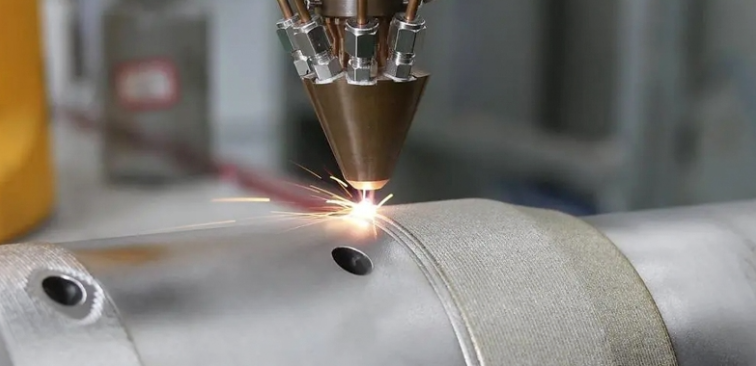

Over time, human exploration in the laser field has continued to break boundaries, achieving remarkable results. The development of lasers across various wavelength bands—including fiber lasers, CO₂ lasers, green lasers, blue lasers, ultraviolet (UV) lasers, deep ultraviolet (DUV) lasers, and X-ray lasers—has provided strong support for diverse commercial, medical, and industrial applications. Parallel to advancing laser wavelengths, innovations in laser applications have flourished, such as laser cutting, laser welding, laser marking, laser cladding, laser drilling, and laser etching.

With continuous technological progress, laser processing equipment has become increasingly practical and widely used. Products manufactured or processed by lasers have integrated into people’s daily lives, becoming closely intertwined with our daily routines.

III. Laser Industry Chain Overview

The laser industry chain consists of three core segments:

- Upstream: Materials and components, including the manufacturing of optical, mechanical, electronic control, and pneumatic parts for laser processing equipment, as well as the R&D of related control platforms and software systems.

- Midstream: Laser processing equipment manufacturing (core segment of the industry chain).

- Downstream: Application industries, encompassing automotive, steel, shipbuilding, aerospace, consumer electronics, advanced materials, semiconductor processing, machinery manufacturing, medical aesthetics, and electronic industry—where laser processing technologies are extensively adopted.

IV. China’s Laser Market

Laser Industry: Chinese Enterprises’ Market Share Expected to Continue Rising

Driven by China’s sustained economic growth and the development of the manufacturing sector, the strengthened economic foundation will inevitably boost market demand for laser manufacturing and create favorable conditions for technological innovation in the industry. Looking forward, China’s laser equipment industry boasts broad market development potential.

With rising demand in high-power cutting/welding, microelectronic processing, and sensing, the demand for industrial laser equipment is expected to maintain steady growth. Currently, the market demand in the material processing sector is growing rapidly, while the penetration rate of laser systems remains relatively low. As laser processing technology matures and cost-performance improves, the prospects for industrial laser equipment demand are highly promising.

V. Maven Applications in the Laser Industry

- Laser Cutting

- Laser Welding

- Laser Marking

- Laser Cleaning

- Laser Cladding

Post time: Dec-01-2025