Laser Welding – The Influence of Oscillation Parameters on Adjustable Ring Mode (ARM) Laser Welding of Aluminum Alloys

1.Abstract

This study investigates the effects of oscillation amplitude and frequency on the surface quality, macro and microstructures, and porosity of adjustable ring mode (ARM) laser oscillating welded A5083 aluminum alloy plates. The results show that with the increase of oscillation amplitude and frequency, the weld surface quality is improved. As the amplitude increases, the weld cross-section transforms from a “goblet” shape to a “crescent” shape. Microstructural analysis indicates that the grain size of the weld does not decrease with the increase of oscillation amplitude and frequency due to the competition between the stirring effect and the reduction of cooling rate. The weld porosity decreases with the increase of oscillation parameters, reaching a final porosity of 0.22% when the amplitude is 2 mm. Three-dimensional X-ray tomography further confirms the influence of oscillation on pore distribution: large pores tend to aggregate behind the of the molten pool, while small pores show better symmetry. This research provides valuable insights for optimizing oscillation parameters to achieve high-quality laser welding in A5083 aluminum alloy applications.

2 Industry Background

Aluminum alloys have the advantages of light weight, high specific strength, and good corrosion resistance, and are widely used in automotive, high-speed rail, aerospace and other industries. Laser welding has the advantages of high efficiency, small heat-affected zone, and small welding deformation. Therefore, laser welding is an economical welding method suitable for thick plates, which can greatly reduce the number of weld passes. Porosity is a significant defect in laser welding of aluminum alloys, which seriously affects the mechanical properties of welded joints. Therefore, extensive studies have been conducted to reduce and eliminate porosity formation, including optimizing shielding gas, applying dual-beam technology, using modulated laser power systems, and adopting oscillating beam methods. Laser oscillating welding technology stands out for its ability to combine the advantages of laser welding with its own characteristics. Using laser oscillating welding can not only reduce porosity but also improve the microstructure of the weld and enhance weld quality. A large number of studies have mainly focused on various aspects of laser oscillating welding, including porosity reduction, optimization of energy distribution, refinement of grain structure, and characterization of melt flow in the molten pool. The distribution of laser energy plays a crucial role in the temperature distribution and penetration depth of laser welding. At a certain oscillation amplitude, with the increase of scanning frequency, the welding process transitions from deep penetration welding to unstable welding, and finally to heat conduction welding. The results show that increasing scanning amplitude and frequency can reduce porosity, but also significantly reduce the penetration depth of the weld, thereby reducing the mechanical properties of the weld. In recent years, an adjustable ring mode (ARM) laser has been developed, which divides the laser energy into a core with high energy density and a ring with low energy density, aiming to stabilize the keyhole and improve welding quality. Researchers have used ARM laser oscillating welding to weld 6xxx high-strength aluminum alloys under different core/ring power ratios and oscillation widths. The experimental results show that the main factor affecting the weld geometry is the oscillation width, rather than the core-ring power ratio. However, the pore distribution and its inhibition mechanism under the superposition of oscillation and ARM laser have not been studied. In this paper, a new ARM laser oscillating welding technology is adopted to reduce the porosity of the weld, obtain higher penetration depth and better weld quality. A comprehensive study on laser energy distribution, molten pool dynamic behavior, and microstructure under different oscillation frequencies and amplitudes is carried out.

3 .Experimental Objectives and Procedures

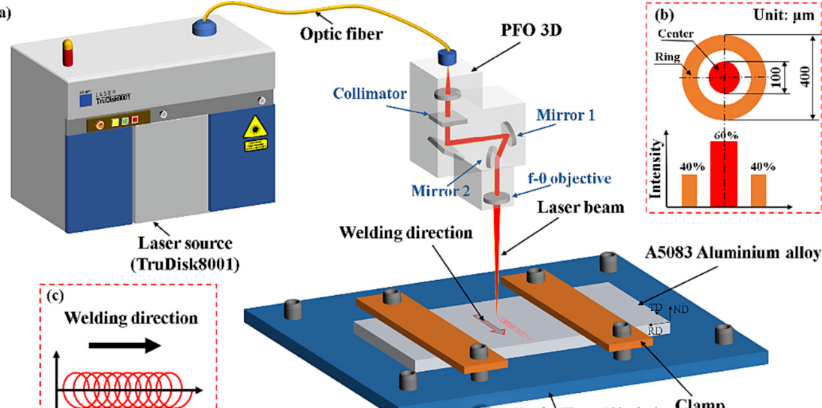

Circular laser oscillating welding technology was used to weld aluminum alloys. The base material (BM) was 5083-O aluminum alloy with dimensions of 300mm × 100mm × 5mm (length × width × thickness), and its chemical composition is shown in the table. Before welding, the samples were polished to remove the surface oxide film, then cleaned with acetone in an ultrasonic bath for 15 minutes to remove surface oil. The laser welding system mainly consists of a Kuka robot, a TruDisk 8001 disk laser, and a 3D PFO galvanometer scanner. The TruDisk 8001 disk laser was used as the adjustable ring mode laser source, with a core/ring fiber ratio of 100/400 μm and a maximum output power of 8 kW (wavelength of 1030 nm, beam quality parameter of 4.0 mm·rad). The laser beam is composed of a core part and a ring part, where the laser in the central core part generates a keyhole (60% of the laser energy), and the laser in the ring part ensures a good temperature distribution (40% of the laser energy), as shown in Figure (b). The focal lengths of the collimator and focusing lens are 138 mm and 450 mm, respectively. During the welding process, a Phantom V1840 high-speed camera and a Cavilux high-frequency light source were used to monitor the welding process in real-time, with a shooting speed of 5000 fps and an exposure time of 1 μs. In this study, the circular beam oscillation trajectory, laser movement path, and instantaneous velocity are defined as shown in the figure.

4 Results and Discussion

4.1 Weld Morphology Characteristics The weld surface morphologies under different laser oscillation modes are shown in the figure. The results show that the weld surface of conventional straight-line welding is rough (roughness of 78.01 μm), with poor continuity of weld ripples and insufficient weld spread. Insufficient weld formation, severe spatter, and undercut were also observed. With the increase of oscillation amplitude and frequency, the weld surface presents dense and uniform fish scales. The surface roughness of welds with oscillation amplitudes of 0.5 mm, 1 mm, and 2 mm is 80.71 μm, 49.63 μm, and 31.12 μm, respectively. There are no irregularities or protrusions caused by spatter. The results indicate that a higher oscillation frequency leads to more regular molten pool flow, stronger stirring effect of the laser beam, and a more ideal weld surface. Fundamentally, the shape of the laser weld is causally related to the movement of the laser beam. During welding, changes in oscillation amplitude and frequency alter the welding speed, thereby affecting the linear energy density and total heat input of the laser. The cross-sectional morphology of the weld is “goblet”-shaped, consisting of two parts: the lower part is the “stem”, and the upper part is the “bowl”. The penetration depth and the “stem” are defined as H1 and H2, respectively, and the widths of the weld (“bowl”) and the “stem” are defined as W1 and W2, respectively. Both weld widths W1 and W2 increase synchronously with the increase of oscillation amplitude, and the weld morphology gradually transforms from “goblet” shape to “crescent” shape. The maximum laser energy density appears at the trajectory overlap. Comparing Figures (b, d) and (c, e), it can be seen that the increase of scanning frequency will increase the trajectory overlap area along the scanning path, making the laser energy distribution more uniform. However, the reduction of the maximum energy density will lead to a decrease in weld depth.

4.2 Molten Pool Behavior To clarify the influence of the scanning path on the molten pool behavior, a high-speed camera system was used to observe the evolution process of the molten pool and keyhole. Figure (a) shows the evolution process of the molten pool under a straight-line path. Figures (b-f) are the evolution diagrams of the molten pool under different oscillation parameters. With the increase of oscillation frequency and amplitude, the rear part of the molten pool becomes more rounded due to the expansion of the molten pool width. As the length of the molten pool increases, the surface fluctuation caused by keyhole eruption decreases during backward propagation. Therefore, the molten liquid metal solidifies smoothly and regularly at the rear end of the molten pool, forming uniform and dense weld fish scales. The figure shows the change of the keyhole opening area during laser welding, which is derived from the high-speed photography images of the molten pool. As shown in Figure (a), during straight-line welding, the keyhole opening size shows obvious fluctuations. Several instances of keyhole closure (0 mm²) were observed, with an average keyhole opening area of 0.47 mm². The increase of oscillation amplitude can also reduce fluctuations and improve stability. This is because in oscillating welding, a larger proportion of energy is distributed to both sides. Therefore, the outlet on the keyhole expands, and the oscillation amplitude increases, thereby increasing the opening area. The increase of amplitude expands the stirring range of the laser beam, leading to the expansion of the radius of the keyhole’s periodic movement. Due to the viscosity of the molten metal and the hydrodynamic pressure acting near the keyhole wall, eddy current movement occurs in the welding molten pool near the keyhole opening. The expansion of the keyhole opening area enhances its stability, avoids the formation of bubbles, and thus significantly inhibits porosity.

4.3 Microstructure The figure shows the EBSD morphology of the weld cross-section under different oscillation frequencies and amplitudes. Near the fusion line of the laser weld, columnar dendrite grains grow toward the weld center. As shown in Figure (a), between the “bowl” and “stem” regions, obvious differences in columnar grain distribution can be observed. Columnar grains are distributed in a U-shape along the “bowl” wall, while in the “stem” region, columnar grains are distributed in a U-shape along the fusion line. During the solidification of the weld, the partially solidified grains in the fusion zone act as nucleation sites for the solidification front and preferentially grow perpendicular to the molten pool boundary along the direction of the maximum temperature gradient. This phenomenon occurs because the high power density of the laser leads to overheating inside the welding pool. The higher thermal gradient G and moderate growth rate R make G/R greater than the threshold for microstructure transformation, resulting in the formation of columnar grains. The temperature gradient G at the weld center decreases, causing the G/R ratio to gradually drop below the microstructure transformation threshold, transitioning to equiaxed grains. Equiaxed grains are located in the central parts of both the “bowl” and “stem”. Since the “stem” of the weld is narrow and close to the base material, it solidifies completely before the “bowl” region during cooling. The solidified “stem” part acts as a nucleation site at the bottom of the “bowl”, promoting the upward growth of columnar grains. The figure shows the straight-line and oscillating welding processes. It is shown that the continuous change of the laser beam position in laser oscillating welding will increase the length of the intermediate molten pool, re-melting the already solidified metal, resulting in a decrease in the grain growth rate r. This can lead to a decrease in G/R in the lower equiaxed grain zone.

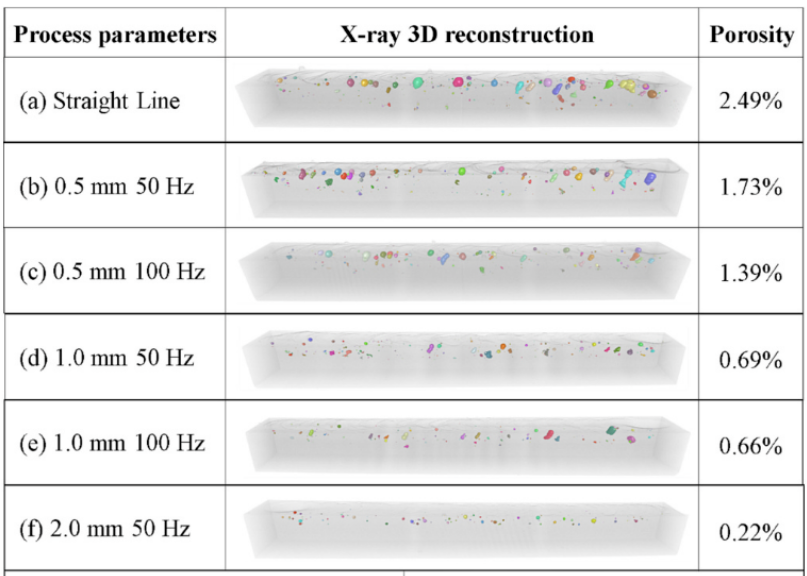

4.4 Porosity Distribution Three-dimensional X-ray tomography was used to conduct a comprehensive inspection of the weld, obtaining the three-dimensional distribution of pores in the weld, as shown in the figure. Porosity is calculated as the total volume of pores divided by the total volume of the weld. By comparing the pore morphology and distribution of straight-line laser oscillating welds and circular laser oscillating welds, it is found that straight-line laser oscillating welds contain more large-volume pores, with a porosity of 2.49%, which is significantly higher than that of circular laser oscillating welds. By comparing Figures (b, c) and (d, e), it can be seen that increasing the oscillation frequency helps to inhibit the formation of pores. Comparing Figures (b, d) and (c, e), it can be seen that the increase of oscillation amplitude also plays a significant role in inhibiting pore formation. When the oscillation amplitude is further increased to 2 mm (Figure (f)), the porosity is further reduced to 0.22%, leaving only small-volume and small pores. The figure depicts the pore area distribution at different distances from the weld centerline, representing the porosity based on pore area size. For straight-line welding, the pore area is symmetrically distributed along the weld centerline, and gradually decreases with the increase of distance from the weld centerline. The results show that keyhole-induced pores are mainly concentrated behind the后壁 of the molten pool at the weld centerline. For laser oscillating welding, the symmetry of pore distribution becomes weaker. The figure shows the pore area at different distances from the weld surface, where the red line represents the boundary between the “bowl” and “stem” regions. In the case of dominant large pores (Figures (a-c)), the pore area above the boundary accounts for more than 85%. This is because the contour transition at the long itudinal boundary is more likely to trap bubbles in the weld pool, and the trapped bubbles tend to migrate upward under the influence of buoyancy. In the case of dominant small pores (Figures (d-f)), the pores are concentrated in the area within 0.5 mm below the boundary line. The short cooling time and small upward displacement may be the reasons for this phenomenon.

5 Conclusions

(1) Different laser oscillation modes have obvious effects on the weld surface. Higher amplitude and frequency can improve surface quality, while excessively large oscillation parameters may increase roughness and cause concave defects.

(2) The weld shape is mainly determined by laser oscillation parameters, which affect welding speed, energy distribution, and total heat input. With the increase of oscillation amplitude, the weld morphology changes from “goblet” to “crescent”, and the aspect ratio decreases.

(3) With the increase of oscillation amplitude and frequency, the molten pool becomes wider and the rear part becomes rounded. The oscillation effect increases the length of the molten pool, which is beneficial to bubble escape and uniform solidification. During straight-line welding, the keyhole opening area fluctuates; relatively speaking, this fluctuation can be reduced, improving welding stability.

(4) Increasing oscillation amplitude and frequency reduces both thermal gradient and growth rate, which is beneficial to the formation of large grain sizes. However, the laser stirring effect is conducive to refining grain size and improving texture strength. Under different laser parameters, the weld hardness remains relatively stable, slightly lower than that of the base material, which may be due to the evaporation loss of magnesium.

(5) Three-dimensional X-ray tomography shows that straight-line welding has higher porosity (2.49%) and larger pore volume than oscillating welding. Increasing oscillation parameters can significantly reduce porosity, even reaching 0.22% when the amplitude is 2 mm. The pore area distribution shifts with oscillation: large pores aggregate behind of the molten pool, and small pores have better symmetry. Large pores are mainly distributed above the boundary between the “bowl” and “stem” regions, while small pores are concentrated below the boundary.

Post time: Aug-14-2025