As we all know, metal products such as aluminum or iron craftsmanship require the use of welding technology. Welding is the most critical step in the manufacturing process of a workpiece. It is impossible to cut materials into the desired shape in one go, making welding an indispensable process.

Welding, as a traditional basic manufacturing process and technology, has not been applied in industry for a long time, but its development has been extremely rapid. In just a few decades, welding has made important contributions to the development of the industrial economy in many industrial sectors and is widely used in various key fields such as aerospace, shipbuilding, automotive manufacturing, bridge construction, electronic information, offshore drilling, and metal structures of high-rise buildings. This has established welding as an important manufacturing technology and a key discipline in materials science, opening a new chapter in joining technology.

Welding, also known as fusion welding, is a manufacturing process and technology that joins metals or other thermoplastic materials (such as plastics) through heating, high temperature, or high pressure.

Modern welding utilizes various energy sources, including gas flames, electric arcs, lasers, electron beams, friction, and ultrasonic waves. Today, I will focus on the welding technology that uses lasers as the energy source.

Principles of Laser Welding Machines

A laser welding machine uses the energy of a laser beam to melt the surface of materials, thereby achieving material joining. The laser beam is focused into an extremely small spot through lenses or reflectors, allowing it to concentrate energy in a very short time. This raises the temperature of the workpiece’s welding area above the melting point, creating a molten state that cools and solidifies to form a weld seam.

Characteristics of Laser Welding Machines

- High Precision: The focused laser spot is extremely small, enabling precise control of the welding position and depth.

- Fast Speed: Laser welding machines offer rapid melting rates, significantly improving welding efficiency.

- Narrow Heat-Affected Zone (HAZ): Welding only affects the local area of the workpiece, without compromising the performance of other parts.

- High Automation: Laser welding machines can be integrated with automated equipment to form efficient, automated production lines.

Advantages of Laser Welding Machines

To summarize:

- Faster welding speed compared to traditional methods.

- More aesthetically pleasing weld seams that require little to no secondary grinding.

- Effective labor savings, greatly helping to reduce production costs.

- Low material loss during welding, with no harmful substances or other pollutants generated.

Disadvantages of Laser Welding Machines

A major disadvantage of laser welding machines is their high initial purchase cost. In the early days, handheld laser welding machines were expensive due to the high price of lasers. However, in recent years, laser prices have dropped significantly, leading to a corresponding reduction in the cost of handheld laser welding machines.

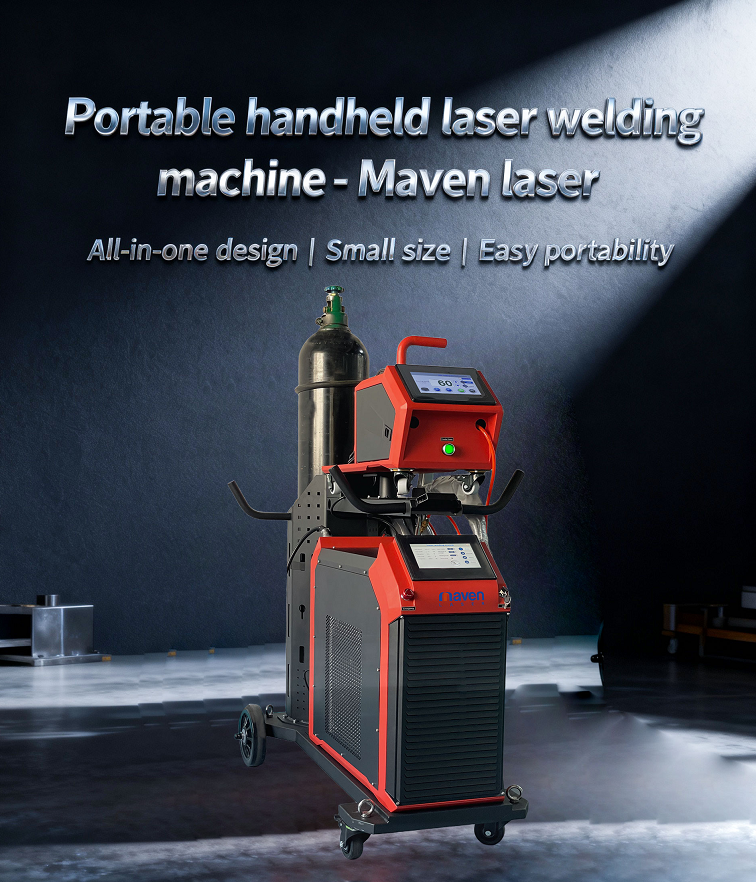

Many users have reported that 1500W handheld laser welding machines are bulky and space-consuming. As shown in the image above, our handheld laser welding machine adopts an integrated small cabinet design, reducing its volume by nearly 50%.

Handheld laser welding machines have significant advantages when welding conventional thin metal sheets. From a production perspective, they are currently an excellent choice.

Equipment Structure of Handheld Laser Welding Machines

A handheld laser welding machine mainly consists of the following components: laser generator, welding head (torch), control card, wire feeder, cooling system,and chassis power supply.

- Laser Generator: The device that emits laser light, serving as one of the core components of the handheld laser welding machine. Due to size and portability constraints, the laser power is typically not excessively high, generally ranging from 1000W to 2000W. Since welding targets metal materials, fiber lasers— which offer superior performance for metals—are commonly used.

- Welding Head (Torch): The component for laser output and wire feeding, consisting of a handheld grip, reflectors, wire feed channel, and nozzle. Different nozzles can be equipped to adapt to various processing environments. Adjusted welding heads can handle hard-to-reach dead corners, corners, and narrow gaps.

- Control Card: Also known as the handheld welding control system or control board (named for its card-like appearance). Unlike traditional welding, handheld laser welding features an intelligent control system that allows operators to adjust parameters such as laser power, focus, and oscillation direction. Once set, operation can begin immediately—even inexperienced operators can master it easily.

- Wire Feeder: A device that delivers welding wire. The wire feeding speed must be adjusted according to power and welding speed; excessively fast or slow feeding will affect weld quality and appearance.

- Cooling System: Handheld laser welding machines use either air cooling or water cooling. Water cooling is the mainstream solution on the market, requiring regular inspection and replacement of cooling water to prevent tank contamination. Air-cooled handheld laser welding machines are an emerging technology in recent years. Their key advantage is the integration of the air cooling system with the chassis, resulting in an all-in-one, highly portable design that can be carried for outdoor operations.

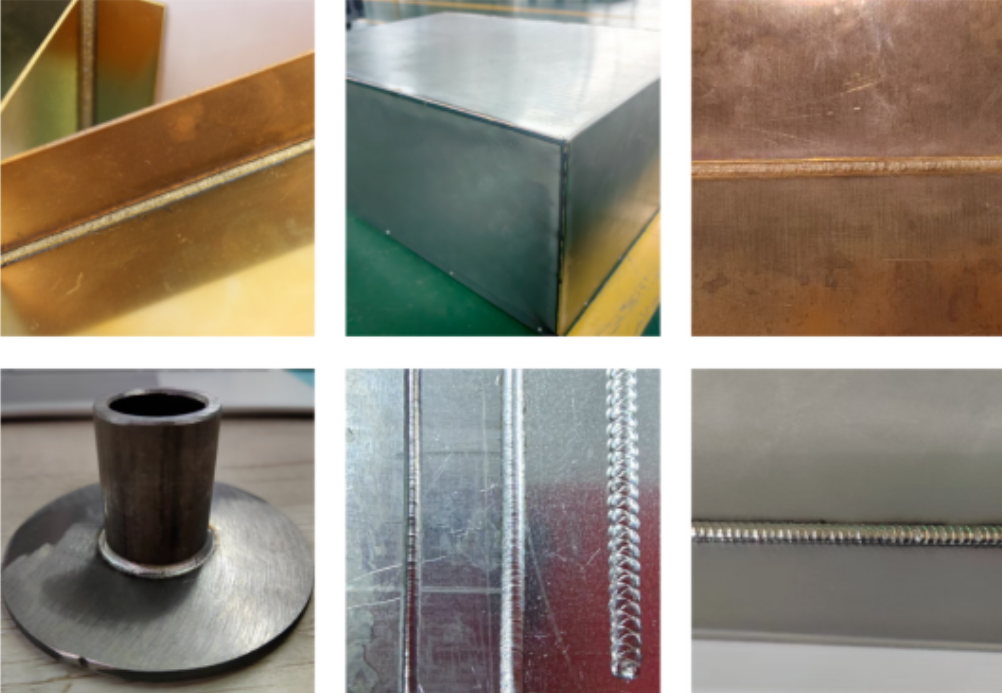

Our handheld laser welding machines offer excellent beam quality, fast welding speed, and strong, aesthetically pleasing weld seams. The ergonomically designed handheld water-cooled torch is flexible and convenient, enabling longer welding distances and welding at any angle on workpieces. As mentioned earlier, the narrow heat-affected zone minimizes workpiece deformation, discoloration, and backside marks. The welding depth is sufficient, ensuring full melting. The torch nozzle is only activated when it touches metal, enhancing safety. Additionally, the machine is easy to learn and operate—ordinary workers can be put on the job after short-term training, significantly reducing labor costs.

Recommended Applications

We recommend using laser welding machines for the following scenarios:

- Large welding areas requiring high efficiency.

- Sheet metal with a thickness of 0.5mm or more.

- Workpieces where weld aesthetics and deformation prevention are critical.

- Metals such as stainless steel, iron plates, and aluminum (laser welding is particularly suitable for these materials).

- Projects with a reasonable budget. If you only plan to spend around 10,000 RMB on a handheld laser welding machine, be prepared for frequent equipment failures. Our 1500W model is priced at just over 20,000 RMB, including parameter adjustment and equipment maintenance tutorials.

- Operators with no prior welding experience.

Important Notes

Handheld laser welding machines are not suitable for welding precision products or very thin materials. Additionally, they cannot weld red copper.

What Type of Welding Wire Should Be Used?

Currently, laser welding machines use either domestic or imported welding wires. Domestic wires are more affordable, while imported wires are higher-priced. The choice of wire depends on the workpiece material:

- Stainless steel workpieces require stainless steel wire.

- Copper workpieces require copper wire.

- Aluminum and aluminum alloy workpieces require aluminum wire.

Parameter requirements vary across different laser welding machines. The weld size should not exceed the wire diameter. When selecting wire, refer to the wire specifications—excessively thick wire may not melt fully, while overly thin wire is unfavorable for welding.

Comparison Between Laser Welding and Traditional TIG Welding

- Welding Speed: The speed difference between laser welding and TIG welding is not extremely large, but TIG welding (especially gas metal arc welding) involves melting the wire, resulting in a slightly slower speed compared to laser welding.

- Welding Effect: Ultimately, welding quality is paramount. Our laser welding machines produce much more aesthetically pleasing welds than TIG welding.

Post time: Dec-03-2025