Shanghai, China – Maven Laser Automation, a Creative manufacturer of innovative laser solutions, is excited to announce its participation in the Shanghai Laser Expo 2025 (LWP), which was held on March 11-13 in Shanghai . Under the theme “Enhancing Accuracy, Looking to the Future,” the company will showcase its latest advances in laser technology, with a focus on its groundbreaking 3d camera scanning autofocus laser printer – a machine that will change the game for an industry that requires ultra-precise, adaptive and efficient laser processing.

About Maven Laser Automation

Maven Laser Automation was starting the fiber laser area since from 2008 ,it was established to apply the laser application solutions that could be replaced by laser to speed up the working efficiency and breakthrough more possibility of current working tool limitation. Maven laser‘s core products include jewelry laser marking/cutting systems, jewelry laser welding machines, Robitc laser laser welding ,laser cutting equipment and laser cleaning machine . By combining precision engineering with intelligent automation, Maven enables customers to achieve unmatched quality, efficiency and possibilities in their production work flows.

Main exhibit: 3D Camera Scanning Auto focus laser printing machine

At LASER WORLD OF PHOTONICS CHINA 2025, Maven will debut its revolutionary 3D camera scanning autofocus laser printer, designed to redefine laser processing standards for complex three-dimensional surfaces.

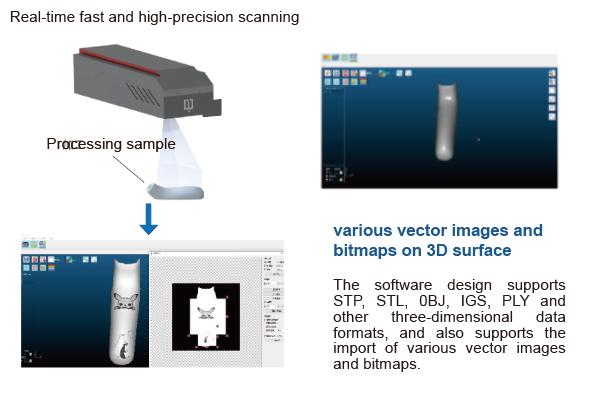

1. Real-time 3D imaging and adaptive processing

The system uses advanced 3D camera scanning technology, real-time automatic focus, positioning, deformation compensation. This ensures consistent accuracy even on irregular or curved surfaces, eliminates manual recalibration, and reduces setup time by 70%.

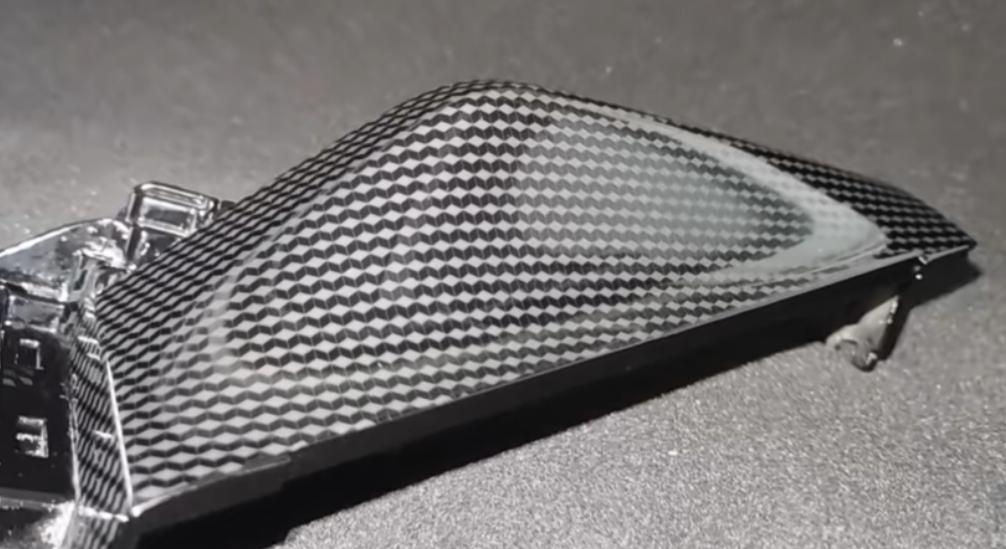

2. Intelligent texture mapping generation

The built-in processing texture mapping generation feature allows users to effortlessly design and apply complex patterns or logos to 3D surfaces. Whether it’s personalized jewelry carving or industrial part identifiers, the system streamlines creative workflows while maintaining micron-level accuracy.

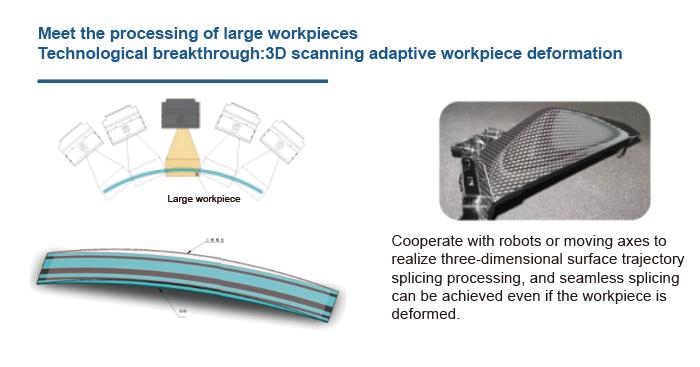

3. High-precision splicing compensation (≤50μm)

A standout feature is its real-time, high-precision compensation ability to overlap or splice processing areas. By achieving alignment accuracy up to 50 microns, the machine ensures perfect continuity in large-scale or multi-stage designs, which is essential for the completion of quality products.

4. Fast attitude calibration and trajectory segmentation

The system’s artificial intelligence software enables instant processing of attitude calibration and intelligent trajectory segmentation, significantly reducing the time required to roll out new components. This flexibility makes it ideal for high-mix, low-volume production environments, such as custom jewelry or prototype development.

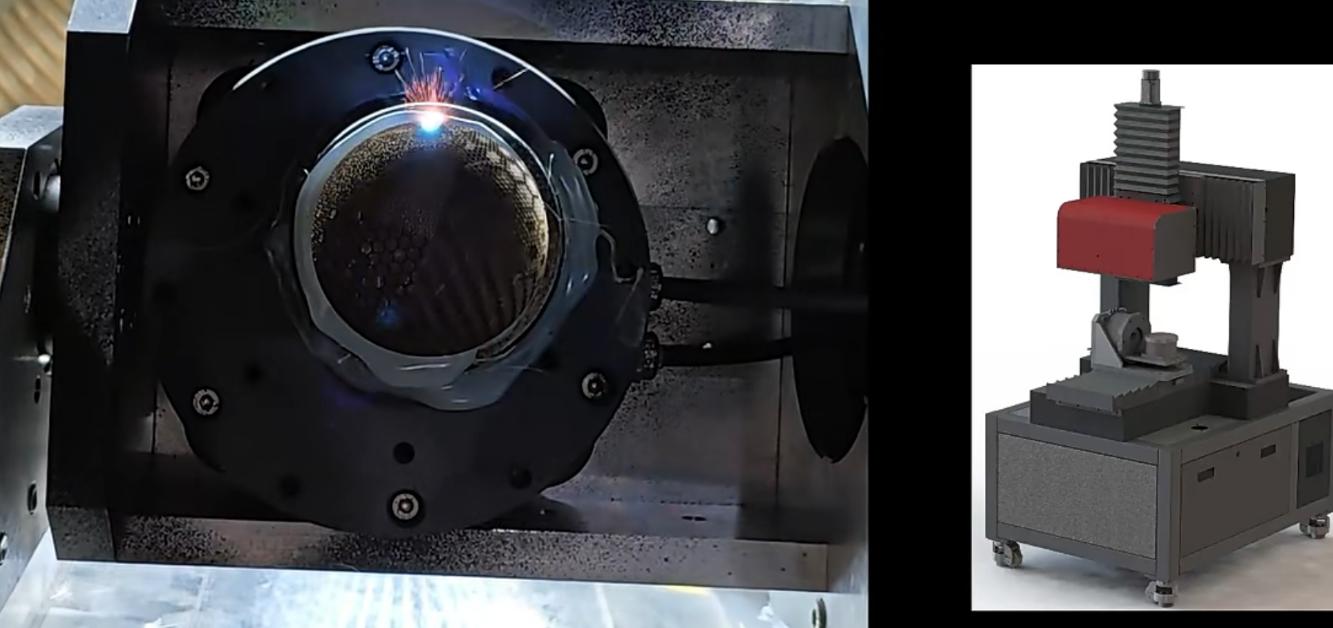

5. 360° seamless processing

Multi-axis motion control, dynamic focusing, 360° no dead Angle processing. Complex geometric shapes, from hollow rings to contoured watch components, can now be carved or marked in a single operation, resulting in increased throughput and yield.

Transform industries with intelligent automation

The 3D camera scanning autofocus laser printer exemplifies Maven’s commitment to bridging the gap between advanced laser technology and real-world industrial needs. By automating traditionally labor-intensive tasks, such as compensating for material warping or aligning multi-part assembly, the system enables manufacturers to reduce waste, speed time to market, and unlock new design possibilities.

“In an era where customization and precision are unquestioned, our goal is to provide solutions that are not only innovative but also intuitive and practical,” said Renee, Maven’s laser Automation market leader. “The technology we are demonstrating at LASER WORLD OF PHOTONICS CHINA 2025 isn’t just about pushing boundaries, it’s about making those boundaries irrelevant to our customers.”

Post time: Mar-18-2025