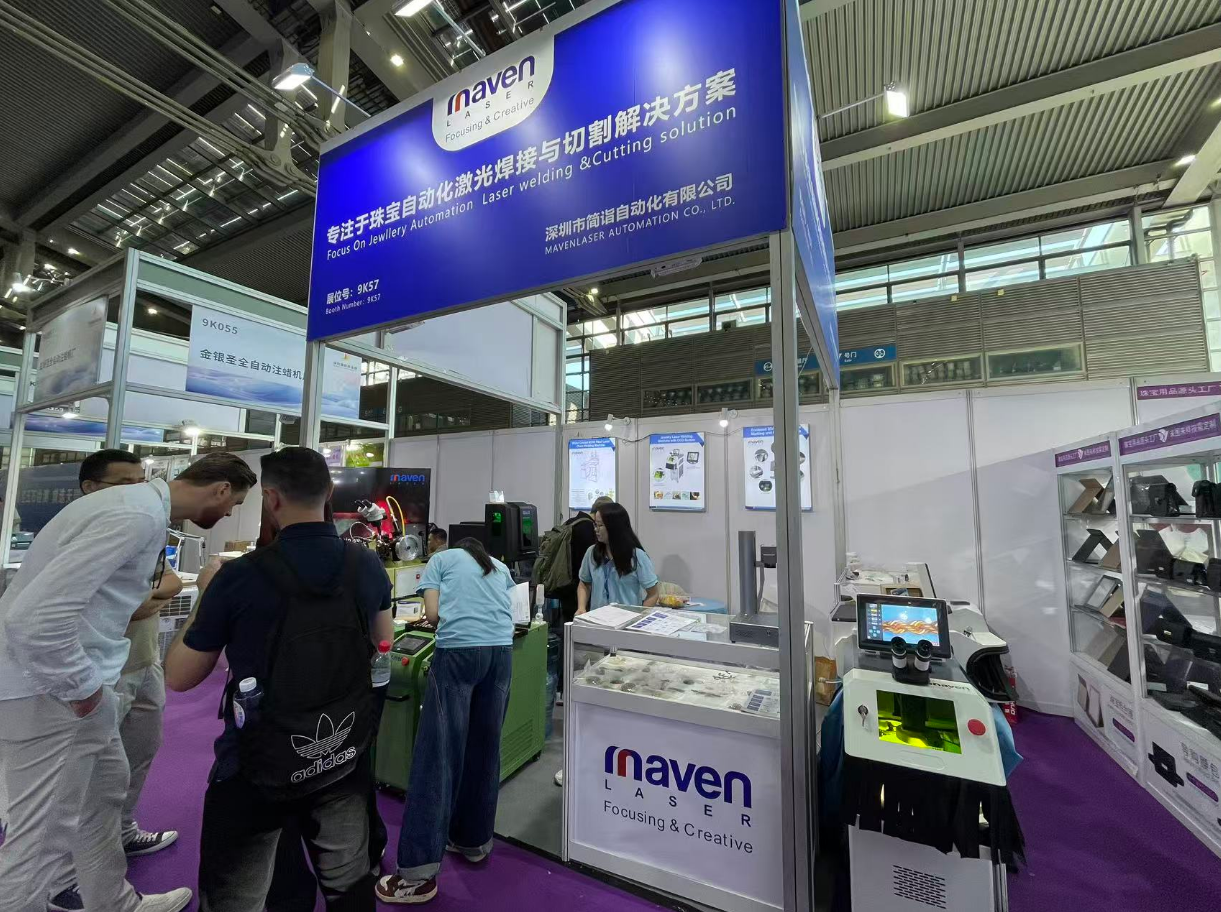

Shenzhen Maven Concludes Shenzhen International Jewelry Show Successfully, Jewelry Automation Technology Attracts Industry Attention

Recently, the highly anticipated 2025 Shenzhen International Jewelry Show officially came to an end at the Shenzhen Convention and Exhibition Center. Shenzhen Maven, a company focusing on automated laser welding and cutting solutions for jewelry, made its appearance at the exhibition with a range of core equipment and innovative technologies. Relying on its precise technological performance and efficient production solutions, the company became a focal point at the event and successfully achieved its exhibition goal of “empowering jewelry manufacturing with technology”.

Eye-Catching Core Equipment, On-Site Recognition of Technological Strength

During the exhibition, Shenzhen Maven focused on showcasing new products such as the Lobster Clasp Welding Machine, Chain Weaving Welding Machine, Jewelry Welding Machine, and Single-Door Electric Marking Machine. At the same time, it visualized the automated advantages of its star product—the Chain Weaving Machine—through on-site simulation demonstrations. The demonstrations intuitively presented the equipment’s outstanding performance in three key aspects:

High production efficiency: Stable output of uniform jewelry chains in a short period;

Low material waste: Minimized raw material loss through precise mechanical control;

Wide adaptability: Compatibility with various jewelry chain weaving processes (e.g., curb chains, Figaro chains).

These features attracted a large number of exhibitors and jewelry manufacturers to stop by for observation and consultation.

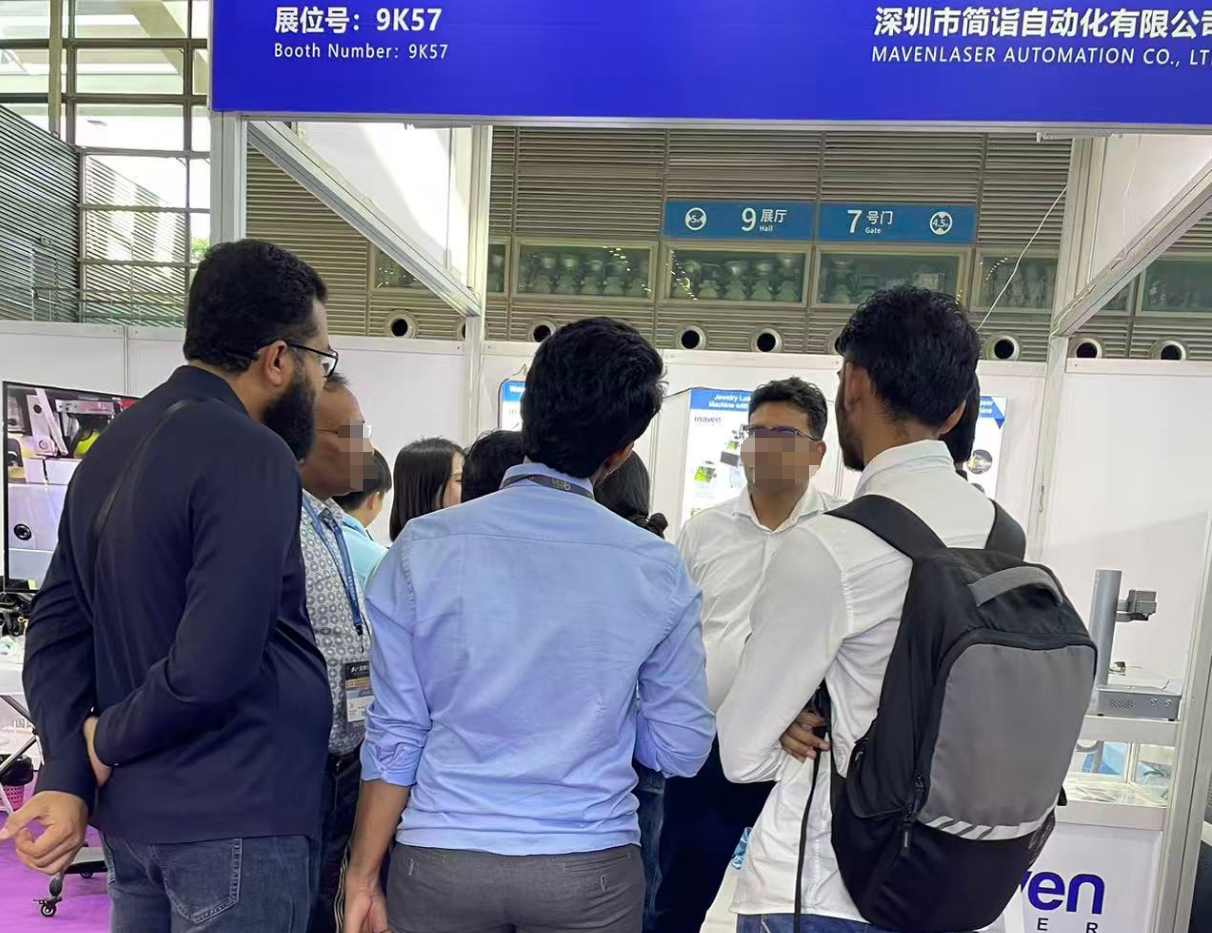

After on-site experience of the equipment operation, many principals of jewelry enterprises stated that Shenzhen Maven’s automated solutions accurately address the industry’s pain points, such as “high labor costs, difficulty in process standardization, and production capacity bottlenecks”. The purchasing director of a jewelry factory in Panyu, Guangdong, mentioned: “Previously, we relied on manual labor for the chain weaving process, which was not only inefficient but also often caused uneven chain links. This time, after seeing the demonstration of Maven’s Chain Weaving Machine, its automated operation and stable quality perfectly solve our production problems. We will further discuss cooperation details in the follow-up.”

Focus on Industry Needs, Conveying the Concept of “Automation Empowering Jewelry Manufacturing”

At this exhibition, Shenzhen Maven did not merely display equipment; instead, it focused on the theme of “automation upgrading in jewelry manufacturing” and conducted in-depth exchanges with on-site customers and industry partners. Aiming at the production needs of jewelry enterprises of different scales, the team provided customized solutions:

For small and medium-sized manufacturers: Recommended cost-effective combinations such as the “Chain Weaving Machine + Single-Door Electric Marking Machine”;

For large enterprises: Planned full-process automated production lines integrating “laser welding + cutting + marking”.

This approach truly took “technology implementation” as the core communication direction.

In an interview, the person in charge of Shenzhen Maven’s exhibition team said: “The jewelry industry is transitioning from ‘traditional manual work’ to ‘automation and intelligence’. We hope to use the exhibition platform to help more enterprises recognize the role of automated

Post time: Sep-16-2025