Technological Breakthroughs in Chain Knitting Machines Drive Efficient Development of the Jewelry Industry

In the field of jewelry manufacturing, chains are indispensable components of many jewelry pieces, and their production efficiency and quality are crucial. Chain knitting machines, as professional equipment, are playing a core role in advancing the continuous development of the jewelry chain manufacturing industry.

Chain knitting machines come in a wide range of types to adapt to the production requirements of different chains. Classified by knitting method, they mainly fall into two major categories: woven tape machines and braided tape machines.

1. Woven Tape Machines

Woven tape machines are further divided into shuttleless woven tape machines and shuttle woven tape machines.

- Shuttleless woven tape machines are extremely common and can efficiently produce various elastic and non-elastic woven tapes, enjoying great popularity in the market. They are further categorized into computerized jacquard woven tape machines and high-speed shuttleless woven tape machines:

- Computerized jacquard woven tape machines use advanced computer pattern-making systems to easily achieve jacquard effects with various patterns, fonts, and symbols, and are used for producing elastic or non-elastic fabrics and garments. For example, when manufacturing decorative chains with complex patterns, computerized jacquard woven tape machines can precisely control 320 heddles and 8 (10) heddle frames, making the patterns vivid and lifelike.

- High-speed shuttleless woven tape machines are known for their high speed and efficiency. Featuring stable and durable operation as well as low noise, they are generally suitable for producing woven tapes for ready-to-wear, such as common single-buckle side chains, double-buckle chains, cross chains, and twist chains, which can all be easily handled.

2. Braided Tape Machines

Braided tape machines, also known as cord braiding machines, are classified into low-speed, medium-speed, and high-speed cord braiding machines based on speed.High-speed cord braiding machines have obvious advantages in producing products with high requirements for strength and braiding precision, such as safety ropes and climbing ropes. For instance, a 90-16-4 high-speed computerized braiding machine adopts advanced computer control technology and can braid ropes at a speed of up to 16 meters per minute. Not only is its efficiency far higher than that of traditional manual braiding, but the braided ropes are also strong and durable, capable of withstanding great tension and meeting the needs of harsh outdoor environments.

II. Outstanding Performance Builds Quality and Efficiency

Chain knitting machines exhibit excellent performance, providing solid support for high-quality chain production and efficient operations.

1. Enhanced Production Efficiency with Advanced Automation

Many chain knitting machines are equipped with advanced automated functions to improve production efficiency:

- For example, some high-speed chain knitting machines use frequency conversion stepless speed regulation, allowing flexible speed adjustment according to production needs;

- They feature sensitive yarn breakage stop—once yarn breakage occurs, the machine can stop immediately to avoid waste and defective products;

- The core-wrapping synchronous feeding and core-wrapping yarn breakage control functions ensure the stability and accuracy of core material delivery.

In terms of energy consumption, they also achieve low energy consumption and high output, reducing production costs.

2. Excellent Precision and Quality Control

Chain knitting machines also excel in precision and quality control:

- Computerized jacquard woven tape machines use precise electronic monitoring heads combined with computer pattern-making systems, enabling simple and fast operation while accurately controlling the presentation of patterns;

- Meanwhile, the machines adopt arbitrary pattern arrangement chain drives, and the pattern plates are connected via Velcro, making pattern changes easy, accurate, and convenient for assembly and disassembly—this allows designers’ ideas to be accurately transformed into physical products;

- Some high-end chain knitting machines use high-quality imported raw materials such as bearings, belts, electrical components, and motors, ensuring more stable operation and a longer service life of parts, further guaranteeing the production quality of chains.

III. Wide Applications Integrating into All Jewelry Scenarios

Chain knitting machines are widely used in the jewelry industry, covering the production of various chains such as necklaces, bracelets, and anklets.

1. Application in Necklaces

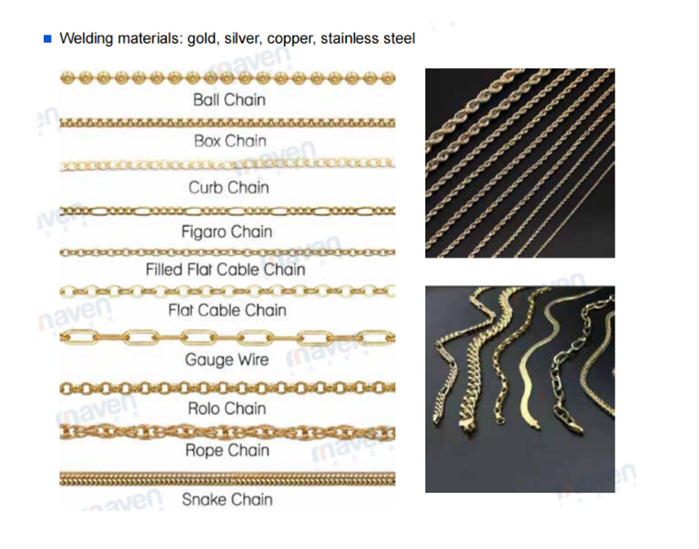

In necklace production, whether it is delicate and tiny collarbone chains or complex multi-layer necklaces, chain knitting machines can produce chains with different link shapes and materials according to design requirements. Common chains like O-chains, snake chains, and box chains can all be efficiently produced by chain knitting machines.

2. Application in Bracelets

For bracelets, from simple and fashionable metal bracelets to luxurious styles adorned with gemstones and pearls, the chain parts can all be created by chain knitting machines.

3. Application in Anklets

Due to the unique wearing environment and design style of anklets, they have special requirements for the flexibility and wear resistance of chains. Through the selection of appropriate materials and knitting processes, chain knitting machines can also perfectly meet the production needs of anklets.

Beyond that, chains produced by chain knitting machines are also widely used in the jewelry accessory field, such as chain shoulder straps for handbags and decorative chains for clothing. These chains not only serve as connecting and decorative elements but also become key components in enhancing the overall quality and fashion sense of products.

IV. Technological Upgrades Leading New Industry Development

With the continuous advancement of science and technology, chain knitting machines are also undergoing constant technological upgrades.

1. Intelligence as a Key Development Direction

By integrating artificial intelligence (AI) and the Internet of Things (IoT) technology, chain knitting machines are expected to realize functions such as self-diagnosis and intelligent adjustment of production parameters in the future. For example, the equipment can automatically optimize parameters like knitting speed and force based on subtle differences in raw materials, ensuring the consistent production of high-quality products. At the same time, with the help of IoT, enterprises can monitor the operating status of equipment in real time and conduct remote maintenance and management, improving production efficiency and equipment reliability.

2. Breaking Through in Adapting to New Materials

As new metal materials, alloys, and high-performance fiber materials are increasingly applied in the jewelry industry, chain knitting machines need to possess the ability to process these new materials. Researchers are committed to improving the mechanical structure and process parameters of the equipment, enabling chain knitting machines to better handle the production of products such as new shape-memory alloy chains and high-strength carbon fiber decorative chains, thus providing more possibilities for jewelry design innovation.

Post time: Sep-22-2025