The Dark Horse Emerges! With “Speed” as Its Blade, It Blazes a New Trail in Efficiency!

In the era of Industry 4.0, speed equals efficiency, and efficiency equals competitiveness. The rapid response capability and long-term stability of metal processing equipment directly determine the ceiling of an enterprise’s production capacity.

Laser cutting has driven a technological revolution in sheet metal processing, thanks to its advantages such as high speed, high production efficiency, high flexibility, strong material adaptability, and short product production cycle. As China’s manufacturing industry undergoes transformation and upgrading, the requirements for sheet metal processing equipment are becoming increasingly higher, which further promotes the development of laser cutting technology. Currently, laser cutting technology is moving towards higher power, larger specifications, and thicker plate processing, while gradually advancing towards intelligence, automation, and digitalization.

In recent years, China’s metal cutting machine industry has developed rapidly, with a large number of enterprises, but their scales and strengths vary. Large enterprises, relying on their advantages in technology, brand, and capital, occupy a dominant position in the market competition; small and medium-sized enterprises, on the other hand, adopt a differentiated competition strategy, focusing on a specific field or product to seek living and development space. For example, some small and medium-sized enterprises have gained a foothold in the fierce market competition by developing specialized cutting equipment or providing customized services to meet the special needs of some customers.

From the perspective of market competition, the global metal cutting machine market presents the characteristic of regional differences. North America and Europe are traditional consumer markets for metal cutting machines. These regions have a high demand for high-end, high-precision metal cutting machines, with a mature market and fierce competition. In the Asian region, especially in emerging economies such as China and India, the metal cutting machine market is growing rapidly with strong demand. Relying on its huge manufacturing foundation and rapid technological upgrading, China has become an important growth driver in the global metal cutting machine market.

At present, the global metal cutting machine market is highly competitive, with major participants including enterprises from the United States, Germany, Japan, China, and other countries. Enterprises from the United States and Germany have technological advantages in the field of high-end, high-precision metal cutting machines, and their products are mainly oriented towards high-end manufacturing industries such as aerospace and automotive; Japanese enterprises have strong competitiveness in the field of precision laser cutting machines and micro plasma cutting machines, and their products are widely used in the electronics and communications industries; Chinese enterprises, relying on their cost advantages and rapid technological upgrading, occupy an important position in the mid-to-low-end market and are gradually advancing into the high-end market.

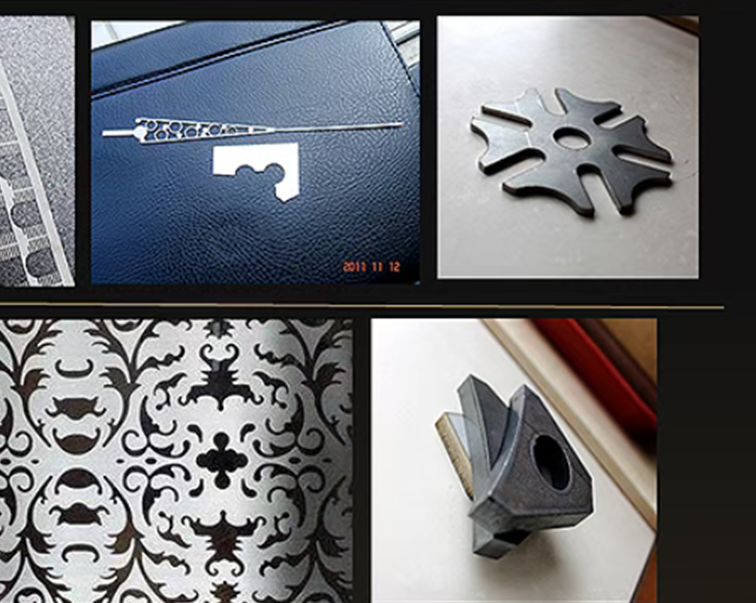

Laser cutting processing uses an invisible laser beam instead of a traditional mechanical knife, featuring high precision, fast cutting speed, no restriction on cutting patterns, material saving through automatic nesting, smooth cutting edges, and low processing costs. It will gradually improve or replace traditional metal cutting process equipment. The mechanical part of the laser cutting head has no contact with the workpiece, so it will not scratch the surface of the workpiece during operation; the laser cutting speed is fast, and the cutting edge is smooth and flat, generally requiring no subsequent processing; the heat-affected zone of cutting is small, the plate deformation is slight, and the cutting seam is between 0.1mm and 0.3mm; there is no mechanical stress on the cutting edge and no shearing burrs; the processing precision is high, the repeatability is good, and the material surface is not damaged; with CNC programming, it can process any 2D pattern, and can cut large whole plates without the need for mold opening, which is economical and time-saving.

Laser cutting equipment is mainly composed of systems such as a laser, a light-guiding system, a CNC motion system, an automatic height-adjusting cutting head, a workbench, and a high-pressure gas blowing system. Many parameters affect the laser cutting process, some of which depend on the technical performance of the laser and the machine tool, while others are variable.

Post time: Sep-22-2025