1. Problem: Slag splash

Laser marking machine (laser marking machine) is a laser beam on the surface of a variety of different substances on a permanent mark. The effect of marking is to reveal the deep material through the evaporation of the surface material, so as to engrave fine patterns, trademarks and text, laser marking machine is mainly divided into, CO2 laser marking machine, semiconductor laser marking machine, fiber laser marking machine and YAG laser marking machine, laser marking machine is mainly used in some requirements for more fine, higher precision occasions. It is used in electronic components, integrated circuits (IC), electrical appliances, cell phone communication, hardware products, tool accessories, precision instruments, glasses and clocks, jewelry, auto parts, plastic keys, building materials, PVC pipes.

This article takes you to a quick understanding of mopa fiber laser marking machine

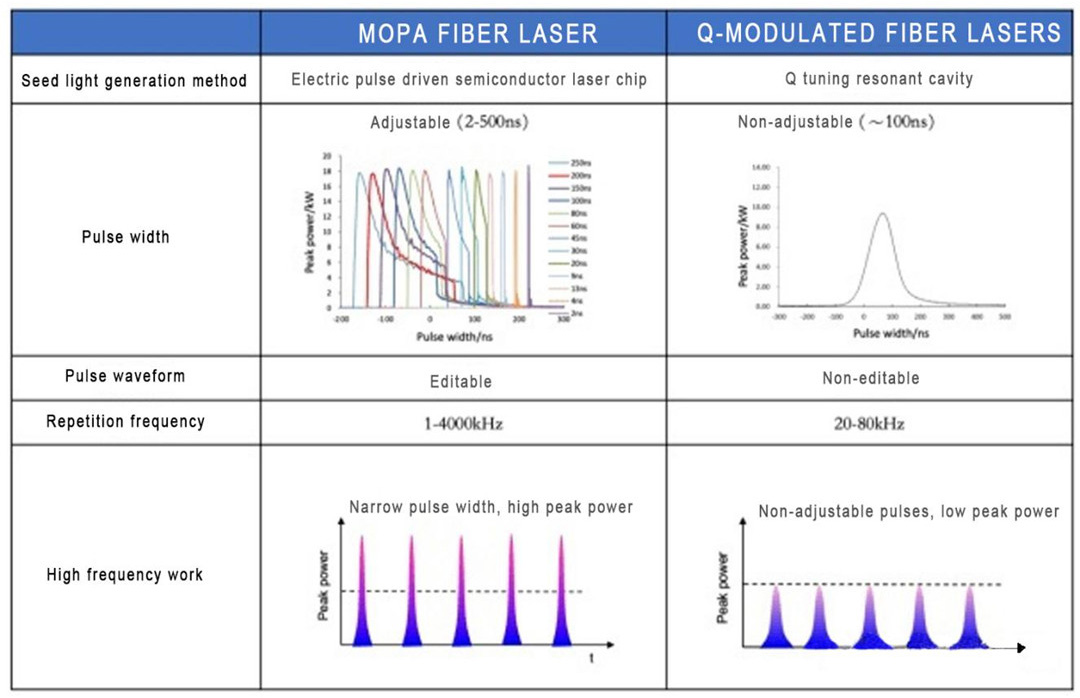

1.The difference between Q modulation and MOPA technology in fiber lasers

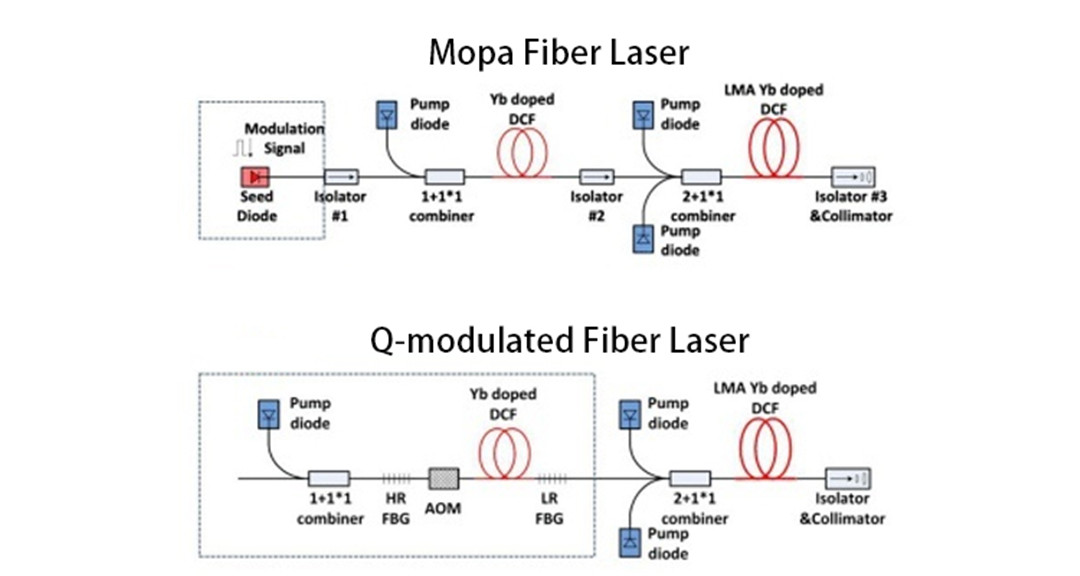

The two main types of pulsed fiber lasers currently on the market for laser marking applications are Q-modulated technology and MOPA technology, which is a laser structure consisting of a laser oscillator cascaded with an amplifier. In industry, MOPA laser refers to a unique, more "intelligent" nanosecond pulsed fiber laser consisting of a semiconductor laser seed source driven by an electrical pulse and a fiber amplifier. Its "intelligence" is mainly reflected in the output pulse width is independently adjustable (the range can be up to 2ns-500ns), and the repetition frequency can be up to megahertz. Q-modulated fiber laser seed source structure is inserted in the fiber oscillation cavity loss modulator, by periodically modulating the optical loss in the resonant cavity to produce a certain pulse width of nanosecond pulse light output. For this often troubling problem, we will make a brief analysis from three aspects: laser internal structure, output optical parameters and application scenarios.

2. Laser internal structure

The internal structure of MOPA fiber lasers and Q-modulated fiber lasers differs mainly in the way of generating the pulse seed light signal, which is generated by the electric pulse driving the semiconductor laser chip, i.e. the output light signal is modulated by the driving electric signal, so there is great flexibility for generating different pulse parameters (pulse width, repetition frequency, pulse waveform and power, etc.). . The pulsed seed optical signal of the Q-modulated fiber laser is generated by periodically increasing or decreasing the optical loss in the resonant cavity to produce a pulsed optical output, which is simple in structure and more advantageous in price. However, the pulse parameters are somewhat limited by the Q-modulated devices and other influences.

The internal structure principle of MOPA fiber laser and Q-modulated fiber laser is schematically shown as follows.

3. Output optical parameters

The output pulse width of MOPA fiber laser is independently adjustable.The pulse width of MOPA fiber laser has arbitrary tunability (range 2ns to 500 ns).

The narrower the pulse width, the smaller the heat affected area and the higher the processing accuracy can be obtained.

The Q-modulated fiber laser output pulse width is not adjustable, and the pulse width is generally output at a fixed value of 80 ns to 140 ns. The MOPA fiber laser has a wider range of repeat frequencies. MOPA lasers can reach high frequency output of MHz. High repetition frequency means high processing efficiency, and MOPA can maintain high peak power characteristics under high repetition frequency conditions. Q-modulated fiber lasers are limited by the operating conditions of the Q-switch and have a narrow output frequency range, reaching only ~100 kHz at high frequencies.

4. Application Scenarios

The MOPA fiber laser has a wide range of parameters, so in addition to covering conventional nanosecond laser processing applications, it can also take advantage of its unique narrow pulse width, high re-frequency, and high peak power to achieve some unique precision processing applications. For example.

Aluminum oxide thin sheet surface stripping applications

Now the more thin and light electronic products, many cell phones, tablets, computers are using thin aluminum oxide as the shell of the product. The use of Q-modulated laser in the thin aluminum plate marking conductive bit, easy to lead to material deformation, the back of the convex package, directly affecting the appearance of the beauty. And the use of MOPA laser smaller pulse width parameters, that can make the material is not easy to deformation, the bottom line is also more delicate bright white. This is because the MOPA laser uses a small pulse width parameters can make the laser stay in the material for a shorter time, but also has a high enough energy to remove the anode layer, so for the thin aluminum oxide surface stripping anode processing, the MOPA laser is a better choice.

Anodized aluminum blackening application

Using laser to mark black logo, model number, text, etc. on the surface of anodized aluminum material, this application has gradually been widely used by Apple, Huawei, ZTE, Lenovo, Meizu and other electronic manufacturers in the last two years for marking the logo, model number, etc. with black marks on the shell of electronic products. For this kind of application, only MOPA laser can process it at present. As the MOPA laser has a wide range of pulse width and pulse frequency adjustment, the use of narrow pulse width, high frequency parameters can be marked on the surface of the material black effect, through different combinations of parameters can also be marked with different grayscale effect.

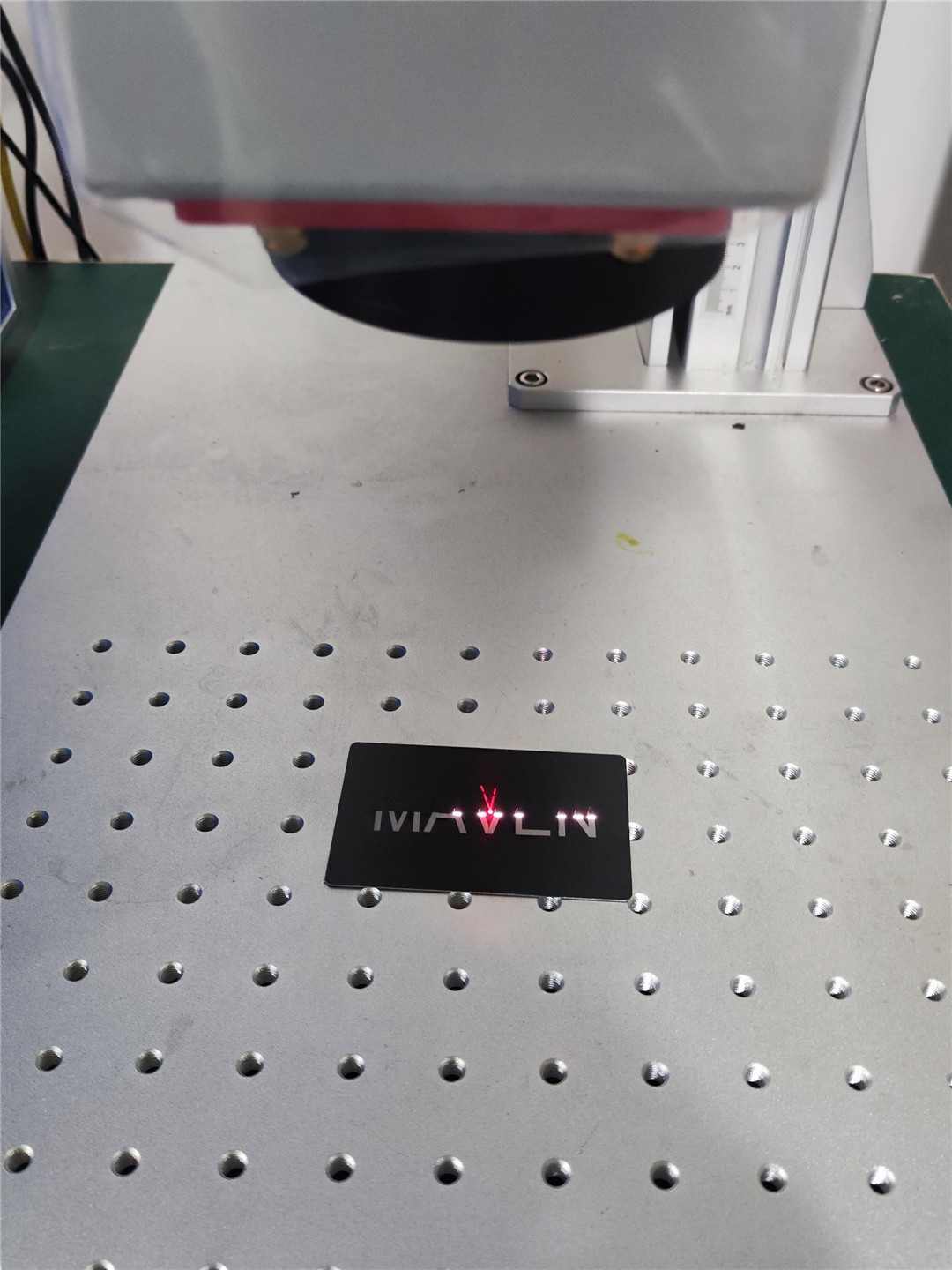

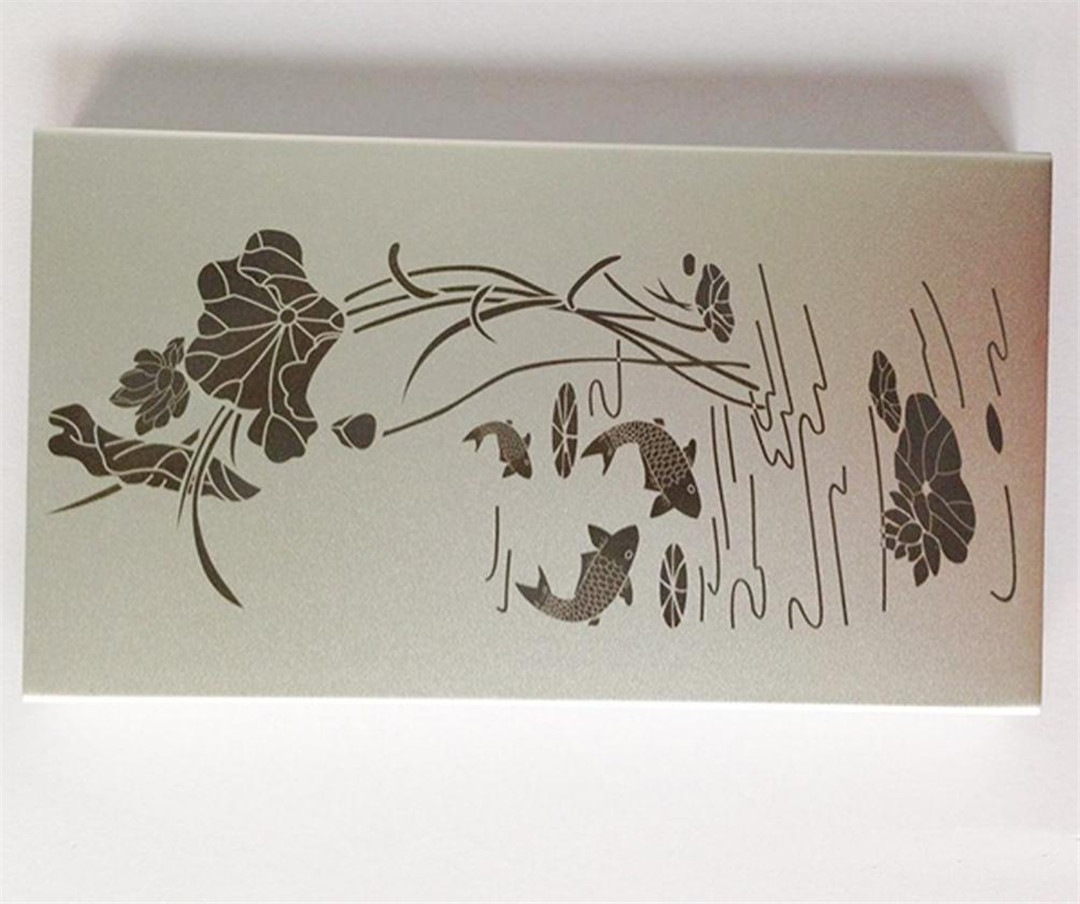

Color Laser Marking

Color laser marking is a new type of laser marking process. At present, this technology is temporarily only MOPA laser marking on stainless steel, chrome, titanium and other metal materials with color patterns. When playing color on stainless steel materials, the laser beam can be adjusted to change the color of the surface layer of the material changes, so as to obtain the decorative effect of different colors, for the stainless steel products industry, you can add the color of the marking pattern, you can edit a variety of text patterns as you wish, convenient and easy to operate: environmental protection and non-pollution; marking speed, can significantly enhance the added value of stainless steel products, enhance the stainless steel products market competitiveness. Adding added value to the product.

In general, the MOPA fiber laser pulse width and frequency independently adjustable, and a large range of adjustable parameters, so the processing of fine, low thermal effect, in the thin plate of aluminum oxide marking, anodized aluminum black, stainless steel color, etc., the advantages of outstanding, can achieve the effect of Q fiber laser can not be achieved. The Q-modulated fiber laser is characterized by stronger marking, and has certain advantages in the deep engraving processing of metals, but the marking effect is rougher. In common marking applications, the main features of MOPA pulsed fiber lasers compared to Q-modulated fiber lasers are shown in the table below. Users can choose the right laser according to the actual needs of marking materials and effects.

| Application Name | Q-modulated lasers | MOPA Lasers |

| Aluminum oxide sheet surface stripping | The substrate is easily deformed, forming convex bags and rough bottom lines | Small pulse width, small thermal residue, no deformation of the substrate, fine and bright white base pattern |

| Anodized aluminum blackening | Only a limited amount of quality dusting is possible | Through a wide range of parameter settings, you can mark out different shades of gray and black black processing |

| Metal deep engraving | Powerful, suitable for deep carving, rough undercut | Weak engraving depth, but fine underline, small taper, can do bright white treatment |

| Stainless steel color | Need to be out of focus, the effect is more difficult to adjust | Can play a variety of colors by adjusting the pulse width and frequency combination |

| ABS and other plastic processing | Easy yellowing effect, heavy feeling, fast | No feeling, not easy to yellow, fine processing |

| Paint stripping of translucent plastic keys | More difficult to remove | Easy to remove clean, clear edge contour, better light transmission, high efficiency |

| PCB board marking barcode, 2D code | High single pulse energy, but epoxy resin is sensitive to laser energy | Adopt small pulse width, medium frequency, barcode, 2D code more clear, not easy to remove and easy to scan |

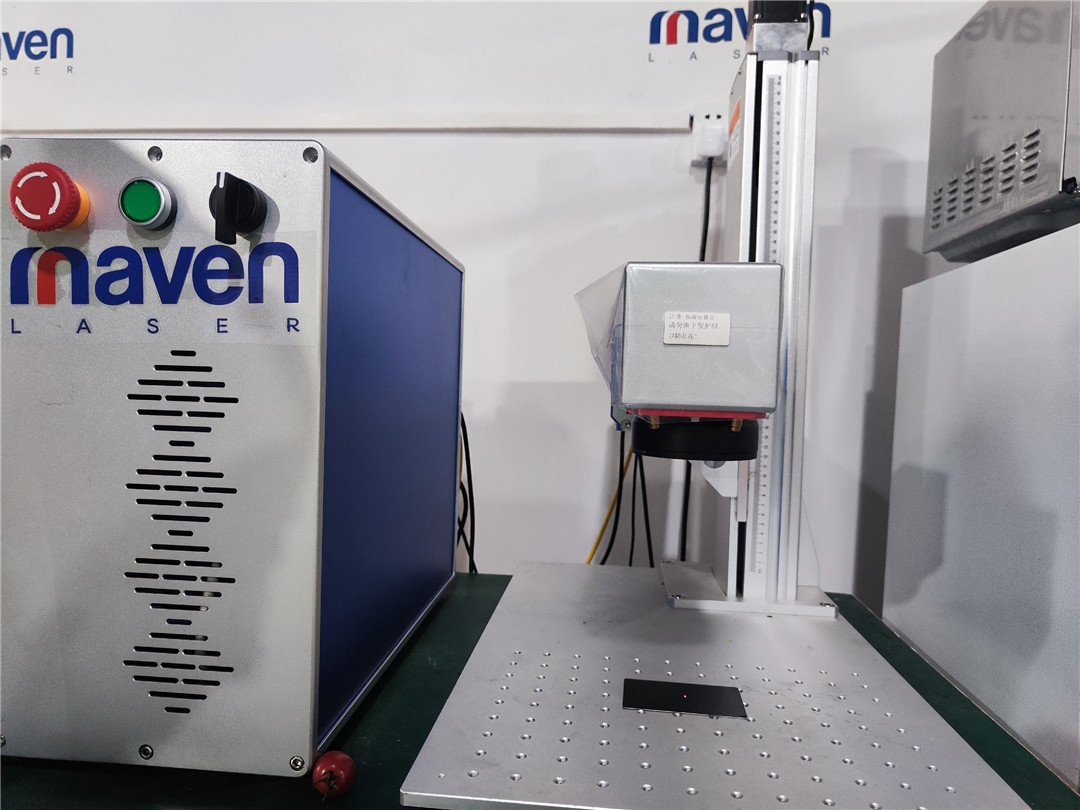

5. Performance Features of MOPA Laser Marking Machine

MOPA laser marking machine belongs to the category of laser marking machine, MOPA laser marking machine uses direct electrically modulated semiconductor laser as the seed source (MOPA) scheme of fiber laser, compared with the Q-modulated fiber laser, MOPA fiber laser pulse frequency and pulse width are independently controllable, through the two laser parameters to adjust with, by The high speed scanning oscillator system allows for constant high peak power output and a wider range of substrates to be marked. With high quality laser beam, low cost of use, 100,000 hours maintenance-free, suitable for aluminum oxide black, 304 stainless steel color, stripping anode, stripping coating, semiconductor and electronics industry, plastic and other sensitive materials marking and PVC plastic pipe industry, marking out the pattern font environmental protection in line with ROHS standards.

Compared with the general laser marking machine, MOPA laser marking machine M1 pulse width 4-200ns, M6 pulse width 2-200ns. ordinary laser marking machine pulse width is 118-126ns, so you can see the MOPA laser marking machine pulse width can be adjusted in a wider range, so you can understand why some products ordinary fiber laser marking machine can not hit the effect, but MOPA laser marking machine can do. laser marking machine can do.

However, many customers purchase MOPA laser marking machines expecting the same processing speed as ordinary fiber laser marking machines, but this is obviously not the case. The two technologies are different. When engraving color effects, the machine needs to mark with minimal shadow effects at high frequencies, which allows for high resolution engraving, but at the same time engraving speed is relatively much slower. In addition, in the metal depth engraving, MOPA laser marking machine may not have the advantage, because there is no advantage on the single pulse energy, but the effect is delicate in terms of and better than the general laser marking machine on a large scale. Therefore, before customers choose to buy MOPA laser marking machine, they need to understand the advantages and disadvantages of this type of laser marking machine.

MOPA laser marking machine is suitable for fine marking process of metal and non-metal materials, such as digital product parts laser engraving black, cell phone back cover, IPAD, aluminum black, cell phone keys, plastic translucent keys, electronic components, integrated circuits (IC), electrical appliances, communication products, bathroom sanitary ware, tool accessories, cutting tools, glasses and clocks, jewelry, auto parts, luggage and bags, cookware, stainless steel products and other industries.

Maven Laser Automation Company has been focusing on laser industry for 14 years, we are specialized in laser marking, we have fiber laser marking machine, CO2 laser marking machine, UV laser marking machine, in addition, we also have laser welding machine, laser cutting machine and laser cleaning machine, if you are interested in our machines, you can follow us and feel free to contact us.

Post time: Nov-15-2022