Automatic High Fast Speed China YAG CW QCW Fiber Laser Type for Laser Chain Making Spot Welding Machine

Main Features

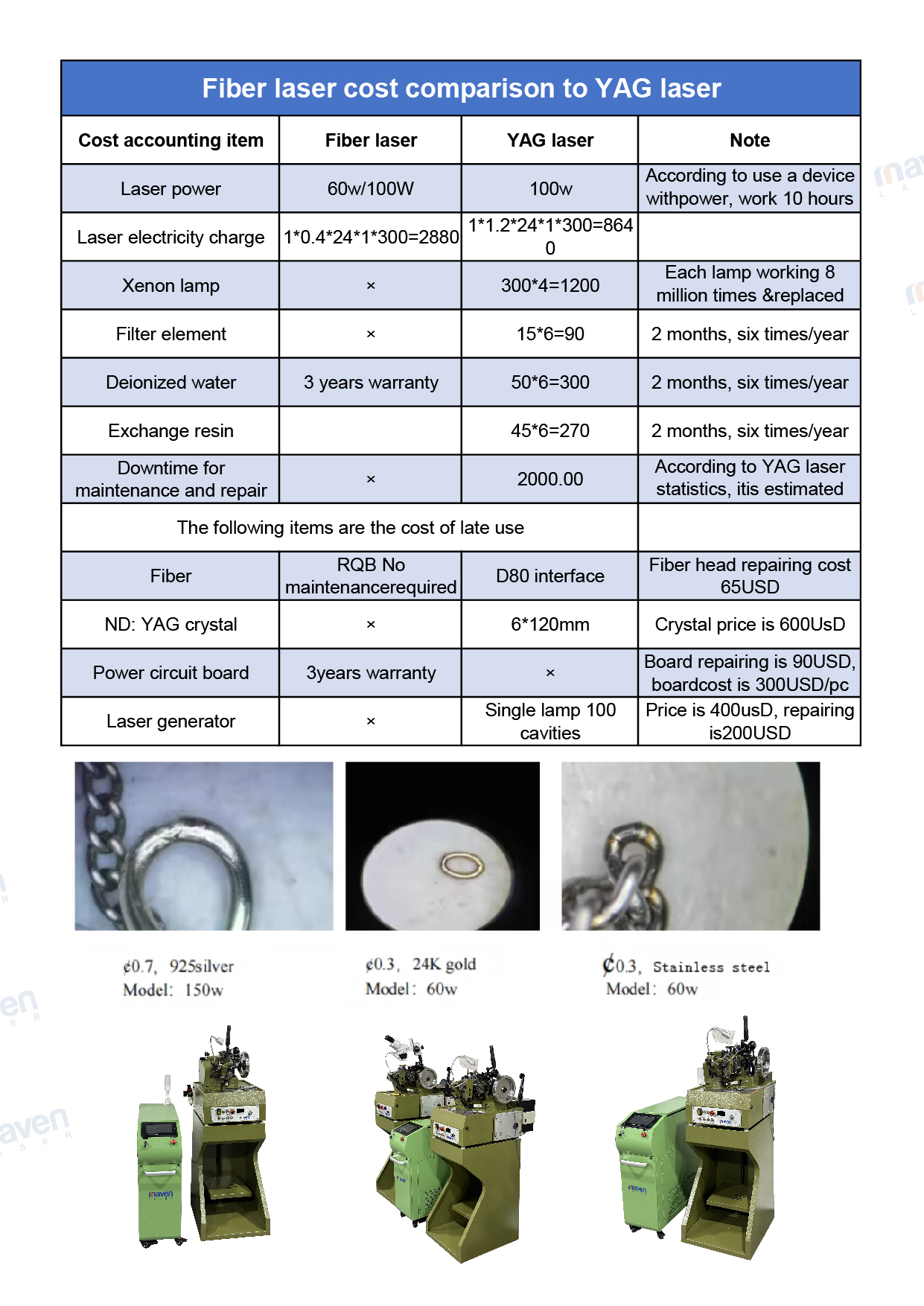

- Strong Material Compatibility: Compatible with a wide range of metal materials, including precious metals such as gold, platinum, and K-gold, as well as common metals and alloys like stainless steel, copper, and titanium, ensuring stable welding performance. Some laser models even support dissimilar material welding, such as copper-brass and titanium-gold joints.

- High Processing Precision: Laser models can weld fine chains with a diameter of 0.12-0.6mm, producing pollution-free weld spots with strength not lower than the base material. Plasma models also handle chain processing with wire diameters of 0.30-0.70mm accurately, avoiding issues like chain link skew and uneven dimensions.

- Automated High Efficiency: Automated models integrate chain weaving and welding into a single process. For example, laser weaving-welding integrated machines can fully automatically produce twisted chains, eliminating the complexity of manual step-by-step operations. The LX1013 plasma model operates at a speed of 80-200rpm, significantly improving chain production efficiency and adapting to large-scale manufacturing.

- Eco-friendly and Stable: Laser models adopt non-contact processing, featuring no noise, no stress, and no need for additional welding agents. Some models are equipped with gold-plated chambers, offering corrosion and heat resistance, a service life of 8-10 years, and a xenon lamp lifespan exceeding 8 million cycles, ensuring strong operational stability.

Application Scenarios

Primarily used for producing various metal chains such as single-clasp sideways chains, double-clasp chains, and cross chains. It is suitable for mass production of jewelry chains (e.g., necklaces and bracelets) in the jewelry industry, as well as processing common metal chains in the hardware accessories field. Additionally, it plays a role in chain repair and personalized chain customization scenarios, such as repairing broken precious metal chain links or customizing special-style chains like twisted chains and spliced chains.

Write your message here and send it to us