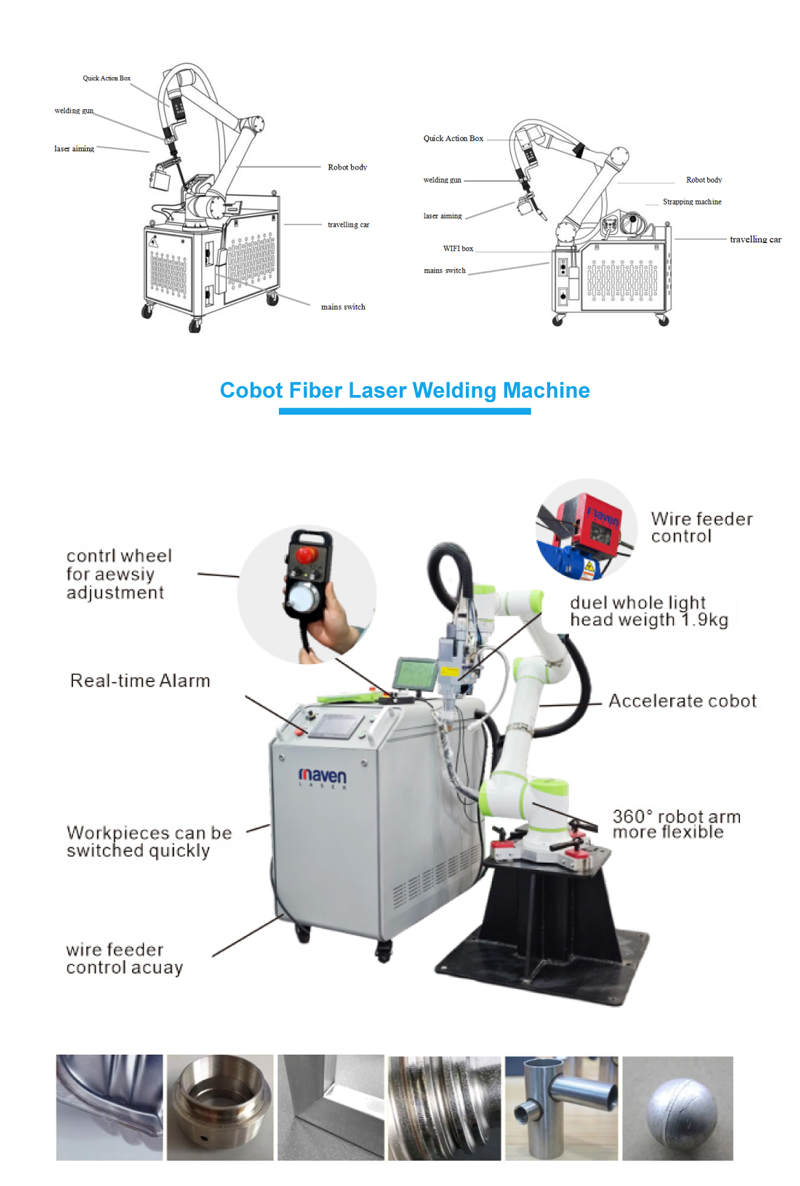

Collision-Proof Weld Seam Tracking Payload Collaborative Robot 6 Arm for Metal Materials Automatic Cobot Laser Welding Machine

Core Advantages

-

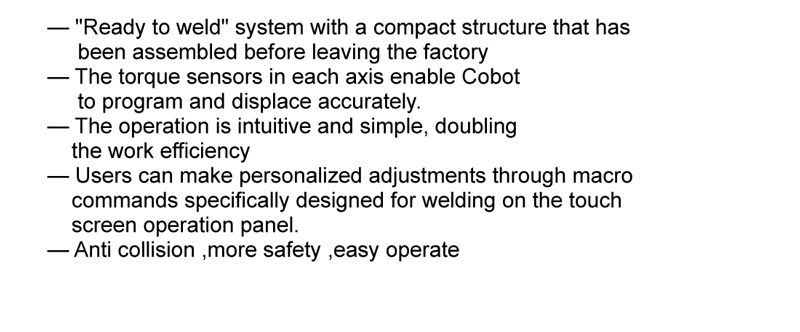

Safe Collaboration without Guardrails: Equipped with collision detection, force feedback sensors, and safety monitoring modules, it can quickly stop or retreat when in contact with the human body. Compliant with the ISO 10218 safety standard, it can be directly deployed on production lines to work in close proximity with humans, saving workshop space.

-

Flexible Adaptation for Multi-Scenario Use: Supports flexible 6-axis/7-axis movement with a repeat positioning accuracy of ±0.02mm. It can handle mass production of auto parts and electronic components, as well as adapt to customized welding needs for small-batch, multi-variety production, and performs exceptionally well in narrow spaces.

-

Easy Operation, Lowered Threshold: Features drag-and-drop teaching and offline programming functions. No professional programming knowledge is required to quickly set welding parameters and paths, allowing new operators to get started quickly and significantly shortening production line debugging cycles.

-

Intelligent, Efficient, Stable, and Reliable: Integrates visual positioning and automatic weld seam tracking systems to real-time correct welding deviations and reduce manual intervention. With high electro-optical conversion efficiency and strong welding consistency, it avoids quality fluctuations in manual welding while reducing workers' labor intensity.

Application Scenarios

- Automotive Industry: Welding of auto parts (such as instrument panel brackets, door hinges), new energy battery trays, and metal structures of charging piles.

- Electronics and Precision Manufacturing: Welding of electronic component pins, small hardware accessories, and medical devices (such as surgical instrument connectors).

- General Machinery: Welding of hardware tools, pipe joints, sheet metal parts, and lightweight products (such as aluminum alloy frames).

- Small and Medium-Sized Enterprise Scenarios: Suitable for production needs with medium batch sizes and frequent product changes. It can be quickly deployed without large-scale workshop renovation, featuring high cost performance.

Write your message here and send it to us