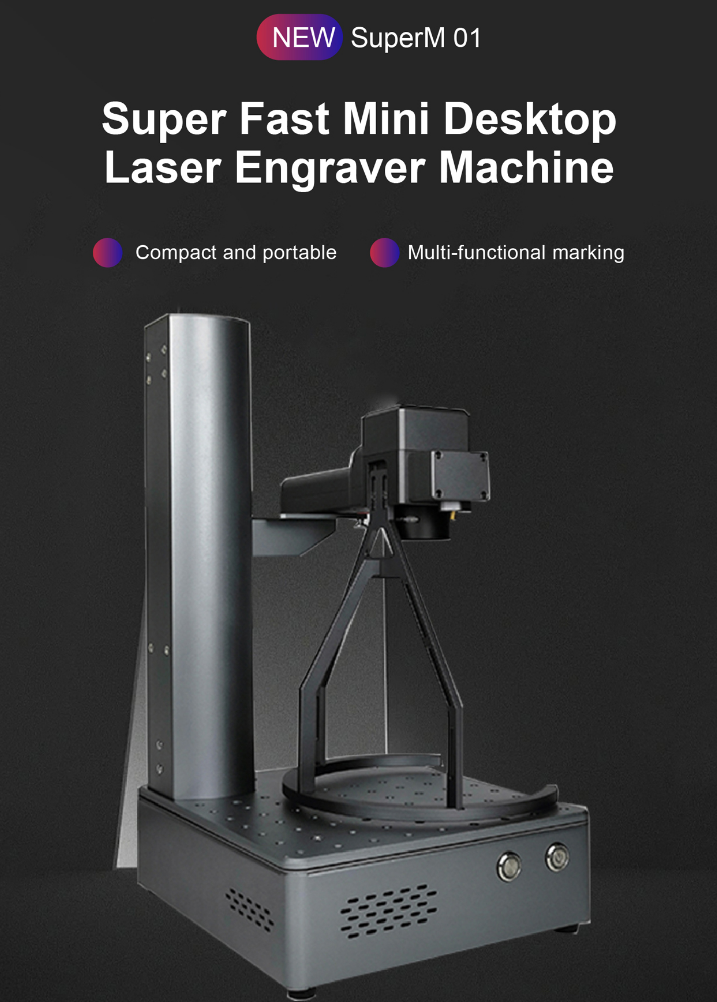

High-Quality Portable Metal 20w 30w Mini Desktop Laser Marking Engraver Machine

Handheld Laser Marking Machine

It is applied in numerous fields including electronic appliances, automobile manufacturing, medical devices, aerospace, food packaging, and jewelry. For example, in the automotive industry, it marks traceability codes on engine parts to facilitate quality traceability; in the consumer electronics field, it engraves brand logos and model information on mobile phone casings to enhance product recognition.

Marking Machine Core Advantages:

**High Precision and Clarity**:Whether on tiny electronic component pins or the surface of large mechanical parts, it can achieve clear and long-lasting markings, meeting the strict requirements of precision manufacturing.

- **Strong Adaptability**:It supports marking on products of various materials and complex shapes, efficiently handling tasks ranging from traceable QR codes on food packaging, anti-counterfeiting marks on auto parts, to compliance numbers on medical devices.

- **Efficiency and Stability**:With a high degree of automated integration, it can seamlessly connect with production lines to realize batch continuous operations. Moreover, the marking process features low energy consumption and no consumables (for types like laser marking machines), reducing long-term operational costs.

- **Environmental Friendliness and Durability**: Advanced technologies such as laser do not require ink or solvents, avoiding pollution. The markings are wear-resistant and corrosion-resistant, capable of withstanding...

New industrial grade small laser marking machine, using the most advanced integrated process.

The development cycle of up to 2 years, fully verified by 100 customers on-site, launched the series of products, easy to operate.

With our 6KG miniature marking machine successfully replaced the traditional marking equipment of about 150KG, to achieve the last kilometer after-sales problem.

Standardized mass production ensures the consistency of quality, and the cost is greatly reduced.

The successful miniaturization of the laser marking industry greatly reduces logistics costs and after-sales costs, and makes the cost of production enterprises more advantageous.