High Speed Fully Automatic for K-Gold & 925 Silver Jewelry & Hardware CW Fiber Laser Chain Welding Machine

II. Core Functions and Technical Features

-

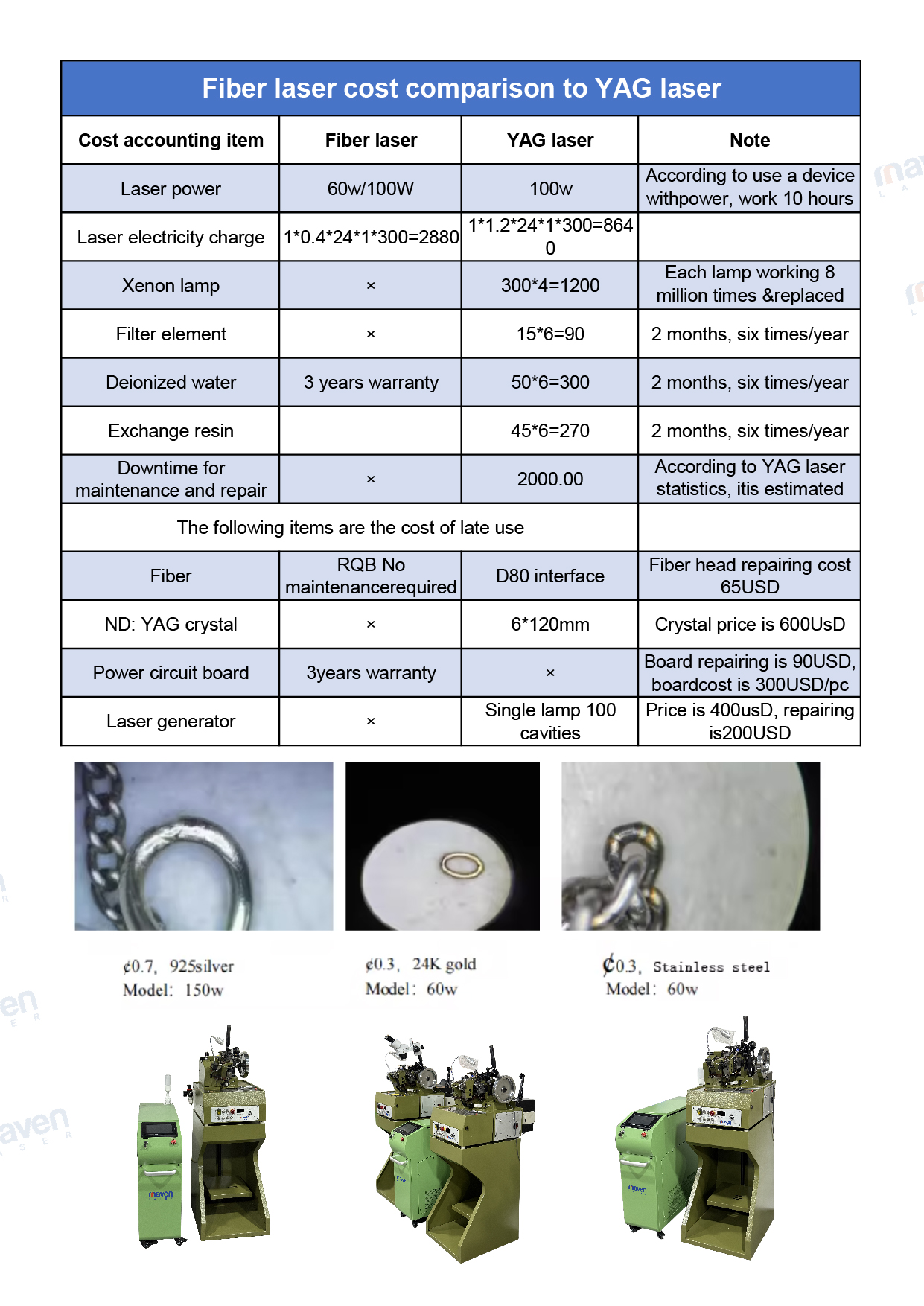

Precise Welding, Ensuring Aesthetics and StrengthWelding precision reaches 0.01mm, supporting "point-to-point" focused welding. The minimum weld mark diameter can be as small as 0.1mm, meeting the high requirement for "no obvious weld marks" in jewelry and accessories.After welding, the tensile strength of the joint is ≥ 80% of the raw material strength, preventing chain breakage during wear or use.

-

Multi-Material Compatibility, Covering Mainstream Woven Chain MaterialsIt can weld woven chains made of various metals without frequent accessory replacement:

- Precious metals: Silver, gold (K gold, solid gold), platinum;

- Common metals: Stainless steel, copper, zinc alloy, aluminum alloy;

- Special materials: Gold-plated or silver-plated woven chains (low-temperature welding mode avoids plating peeling).

- High Automation, Reducing Labor Dependence

- Semi-automatic models: Equipped with chain positioning fixtures. After manual loading, they automatically complete the "positioning → welding → cooling" process;

- Fully automatic models: Integrate feeding, positioning, welding, and inspection functions, and can be connected to production lines. A single unit can achieve a daily capacity of 5,000-10,000 woven chains;

- Some high-end models support "one-click switching of welding parameters," quickly adapting to woven chains of different specifications (e.g., 1mm, 2mm wire diameters).

- Safety and Stability Design

Equipped with laser protective covers (for laser welding models) and high-temperature protective gloves, complying with industrial safety standards;

Built-in overload protection and voltage stabilization modules to avoid uneven welding strength caused by voltage fluctuations;

The welding head is made of wear-resistant materials, with a service life of over 100,000 cycles, reducing the frequency of consumable replacement.

III. Core Application Scenarios

The application of chain weaving welding machines is highly focused on "chain product processing," with main scenarios including:

- Jewelry industry: Welding joints of gold, silver necklaces/bracelets, such as O-link chains, cross chains, and twisted chains;

- Accessory industry: Welding affordable accessory chains made of alloy or stainless steel (e.g., collarbone chains, multi-layer chains);

- Hardware accessories: Reinforcing welding of joints for luggage chains, belt chains, and keychain chains;

- Custom processing: Precision welding of personalized woven chains (e.g., engraved chains, special-shaped chains) to avoid deformation during processing.

IV. Key Selection Points

When purchasing a chain weaving welding machine, focus on the following 4 parameters to avoid mismatched needs:

- Chain specification matching: Confirm the equipment’s supported wire diameter range (e.g., 0.3-3mm) and chain types (woven chains, link chains) to prevent welding breakage due to excessively thin wire diameters;

- Automation requirements: Choose manual/semi-automatic models for small-batch customization, and fully automatic models for mass production to reduce labor costs;

- Material compatibility: For welding precious metals (e.g., solid gold), select "low-power laser welding machines" (to avoid excessive metal melting); for stainless steel, "resistance welding machines" are more cost-effective;

- After-sales service and training: Prioritize brands offering "on-site installation + operation training." Some models require regular calibration of the welding head, and the speed of after-sales response affects production efficiency.

V. Operation and Maintenance Notes

- Before operation, check if the equipment grounding is normal; for laser models, ensure the protective cover is closed (to avoid laser direct radiation injury);

- When welding different materials, adjust parameters in advance (e.g., laser power, welding time). It is recommended to perform 3-5 test welds to confirm the effect;

- Clean residual metal debris on the welding head after daily use, check fixture wear weekly, and calibrate welding positioning accuracy monthly;

- Avoid use in humid, dusty environments to prevent internal circuit short circuits or welding head blockage.

Write your message here and send it to us