Multifunctional & Flexible Injection/Die-casting/Stamping Mold & Die Repair Solutions Mold Welding Machine

Main Features

- High Welding Precision: The laser mold welding machine enables micron-level precision control. Some professional models can reduce the laser spot size to 0.1–0.3 mm, making it ideal for welding and repairing precision molds.

- Minimal Heat Affected Zone (HAZ): Laser welding features concentrated heat input and a small heat-affected area, which significantly reduces the risk of mold deformation caused by welding and minimizes the impact on the original performance of the mold.

- Wide Range of Weldable Materials: Capable of welding various metal materials including cold-work high-alloy steel, hot-forged high-alloy steel, nickel-containing tool steel, copper alloy, beryllium copper and high-toughness aluminum alloy.

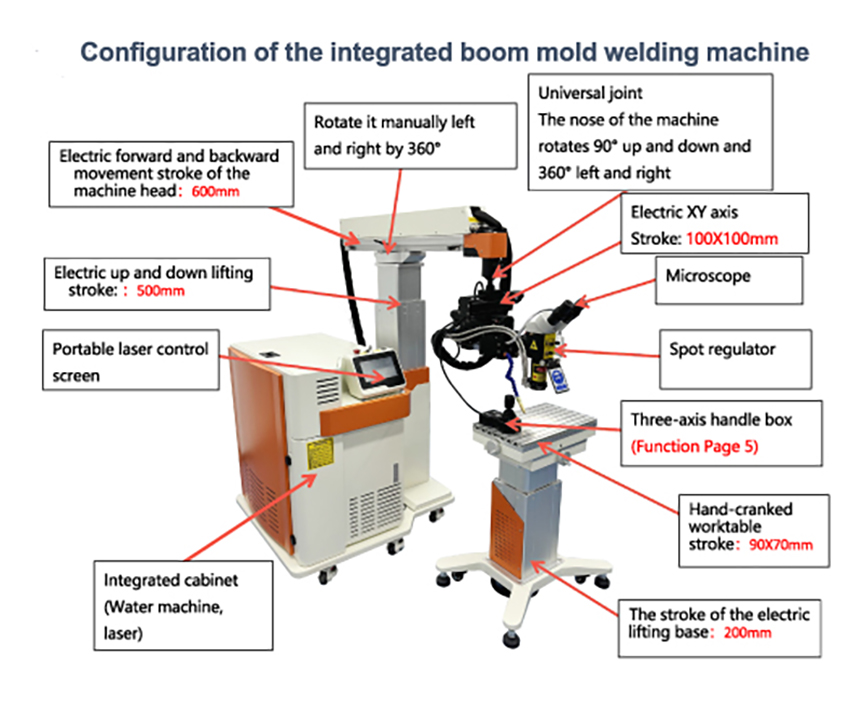

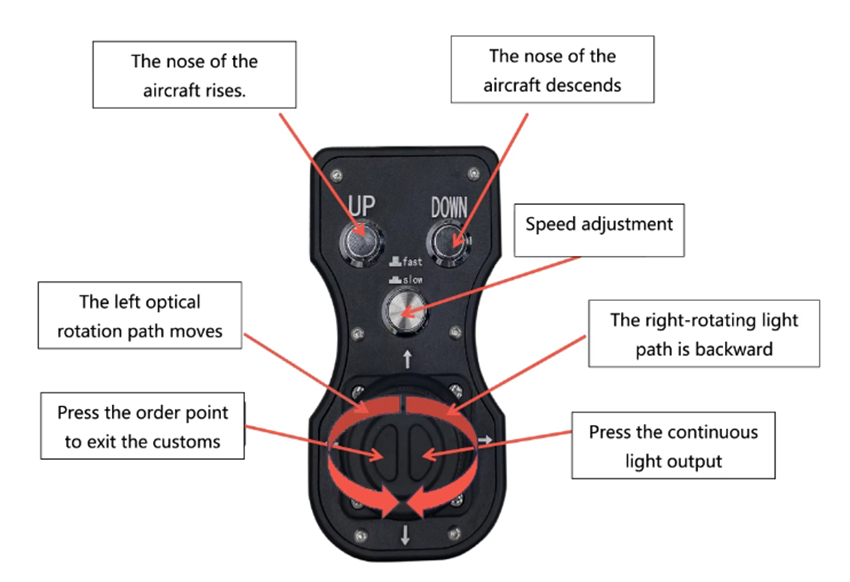

- Easy Operation: The laser head of the laser mold welding machine can rotate 360°, and the entire optical path assembly is rotatable, with motorized vertical lifting and horizontal forward/backward movement. The worktable also supports motorized lifting and 3-axis positioning. Parameter adjustment is mostly controlled intelligently, ensuring simple and efficient operation.

Scope of Application

- Applicable Industries: Widely used in mold manufacturing and molding sectors such as mobile phones, digital products, automotive and motorcycle manufacturing.

- Mold Types: Suitable for plastic molds, casting molds, forging molds, stamping molds, die-casting molds and more.

- Repairable Areas: Effectively repairs minor defects including porosity, cracks, chipped corners, as well as worn mold edges and sealing edges.

Write your message here and send it to us