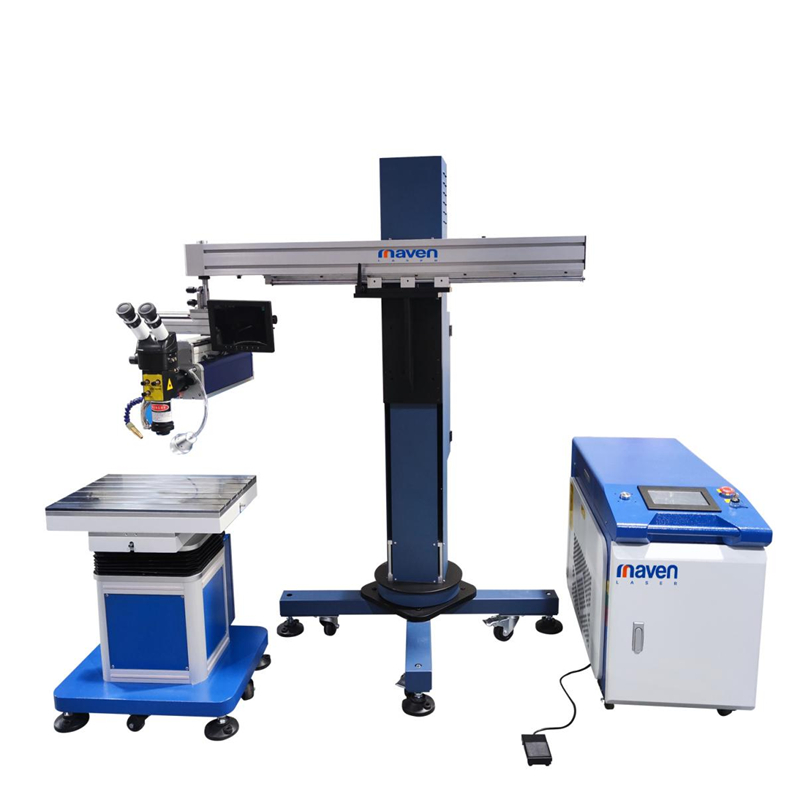

Precision Mold Repair Mold Laser Welding Machine

| Item | Parameter Name | Data |

| Laser Source Parameter | MAX OUTPUT POWER | 1000W/1500W/2000W |

| TOTAL POWER | 4KW | |

| LASER WAVELENGTH | 1080nm | |

| MAXIMUM LASER PULSE ENERGY | 70J/50ms | |

| PULSE WIDTH | 1-50ms | |

| PULSE FREQUENCY | 1-100HZ | |

| Welding Function | SPOT ADJUSTMENT | 0.1-3.0mm |

| SPOT SIZE | 0.2mm-3mm | |

| LENSE SIZE | F150mm | |

| WELDING THICKNESS | 0.1-1.2mm | |

| FOCUS LOCATIONING | Microscope(CCD also can be add) | |

| Control System | LASER SOURCE UPSIDE MOVE LENGTH | 300mm |

| SOURCE MOVE DIRECTION | 360D Degree | |

| LASER HORIZONTAL DIRECTION | Y Axis move | |

| 3D WORKBENCH | X Y manual,Z motorized | |

| Physical Properties And Others | WATER COOL CAPACITY | 1.2P |

| POWER VOLTAGE | 220V±10% 50Hz 30A | |

| WORKING ENVIRONMENT | Clean no rust, 13℃-28℃ | |

| CONSUMABLE | Protected mirror |

Product Advantages

Principle of mold laser welding machine.

The welding machine is mainly applied to fill holes and spot welding trachoma of gold and silver jewelry. Stainless steel laser spot welder is an important aspect of laser spot welder in the application of laser material processing technology.

One of the important aspects, laser spot welding process is heat conduction type, that is, the laser radiation heating the surface of the workpiece, the surface heat through heat conduction to the internal diffusion, by

The laser spot welding process is of the heat conduction type, in which the laser radiation heats the surface of the workpiece and the surface heat diffuses internally through heat conduction. Due to its unique advantages

It has been successfully applied in gold and silver jewelry processing and welding of micro and small parts.

Mold laser welding machine features.

◆Adopt British imported ceramic spotting cavity, corrosion resistance, high temperature resistance, cavity life (8-10) years, xenon lamp life of more than 8 million times.

◆Adopt automatic shading system, eliminating the stimulation to eyes during working hours.

◆10X microscope magnification, cross cursor indication, and automatic shading with high-speed LCD light valve. The protective gas output synchronized with the laser ensures that the solder joint is beautiful and the solder joint will not be oxidized and discolored.

◆The display adopts 7-inch LED screen, which can realize free switching between Chinese and English, and is in line with the international market.

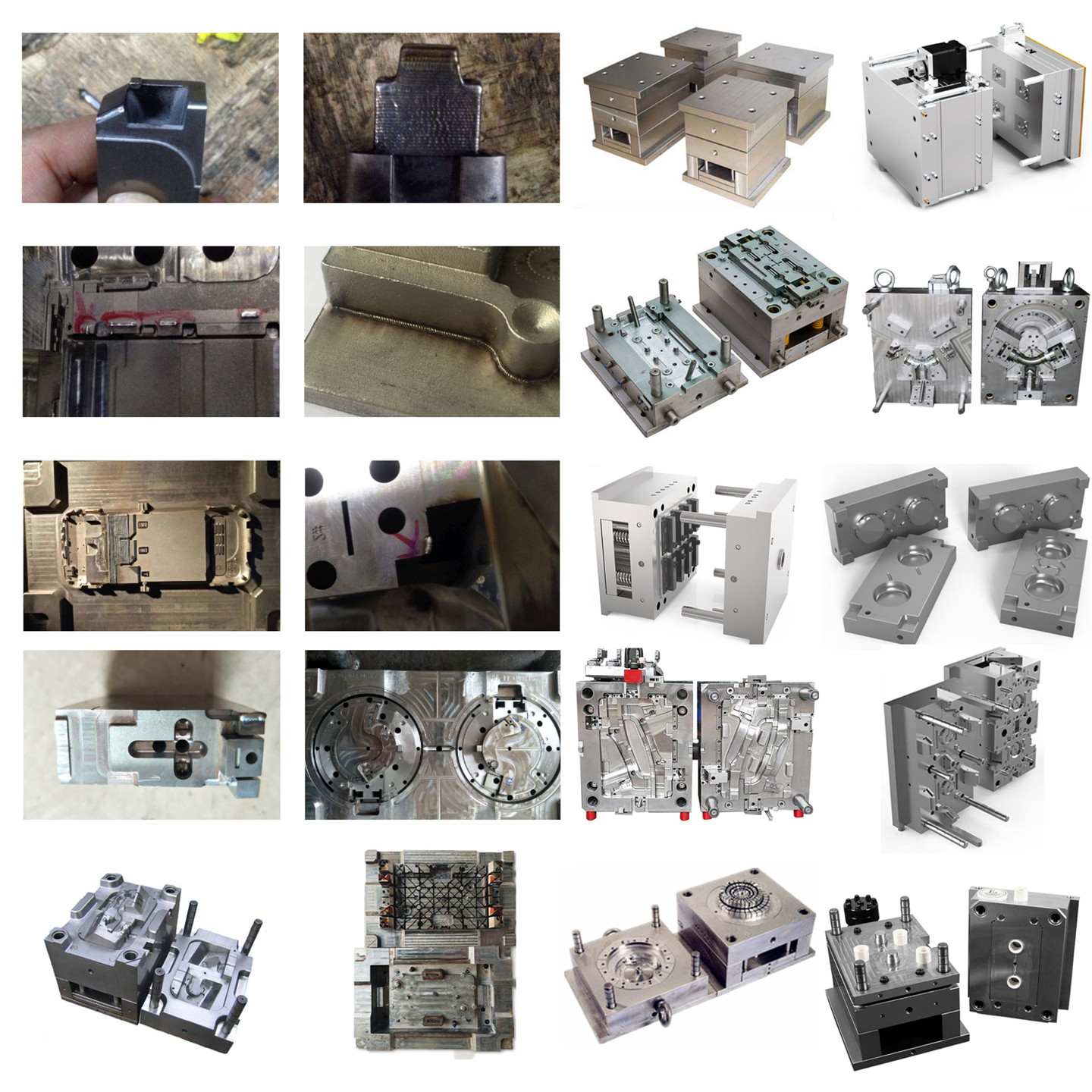

Laser mold welding machine is widely used in mold, precision injection molding, die-casting, stamping, stainless steel and other hard materials such as cracks, chipping, grinding and wear sealing edge repair, welding, cell phone batteries, jewelry, electronic components, sensors, precision machinery, communications, kettles, wine pots, coffee pots, crafts and other industries.

Sample & Application