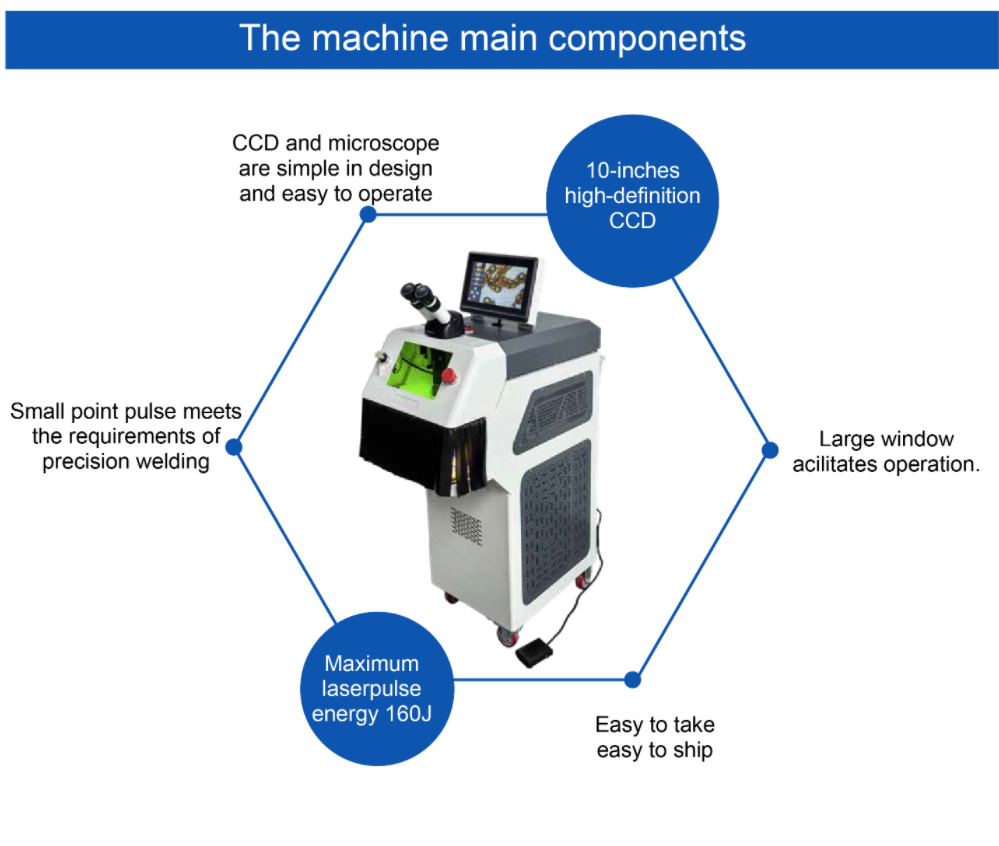

Multifunctional Easy-to-Operate Water-Cooled YAG Spot Welder New Permanent Hardware High Precision Laser Spot Welding Machine

I. Core Advantages

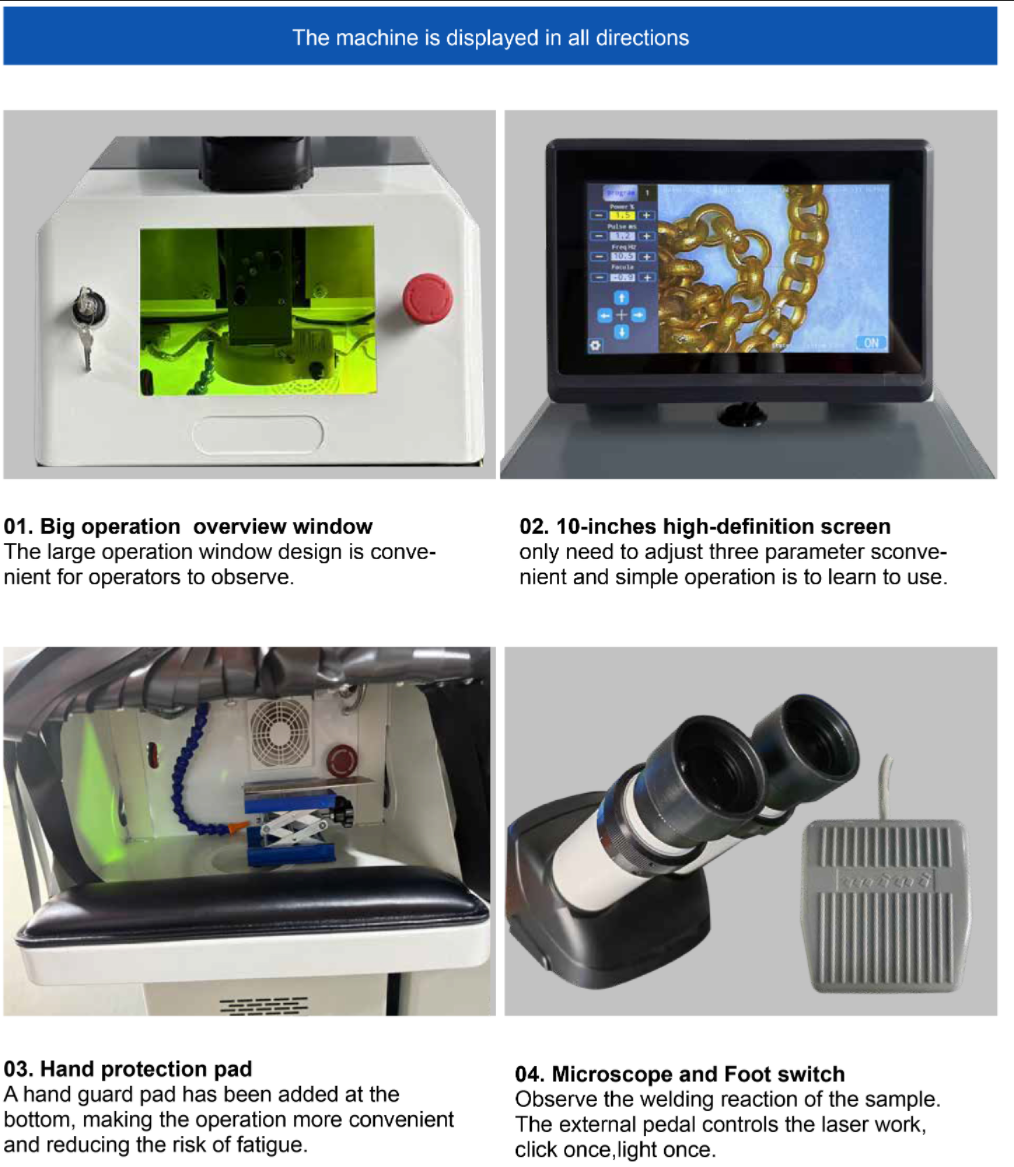

- Ultra-High Precision: Enables 0.1-0.3mm micro-level weld spot control, allowing accurate connection of small structures such as chain links and claw settings. The weld spot has high color integration with the original jewelry, basically achieving an "invisible and seamless" effect and avoiding obvious weld scars from traditional welding.

- Strong Material Protection: Adopts low-temperature welding technology (the temperature of some models is ≤200℃), which can effectively protect heat-sensitive gemstones such as diamonds, rubies, sapphires and jadeites, preventing cracks and discoloration caused by high temperatures. At the same time, it reduces the melting loss of precious metals, with the loss rate controllable below 0.5%.

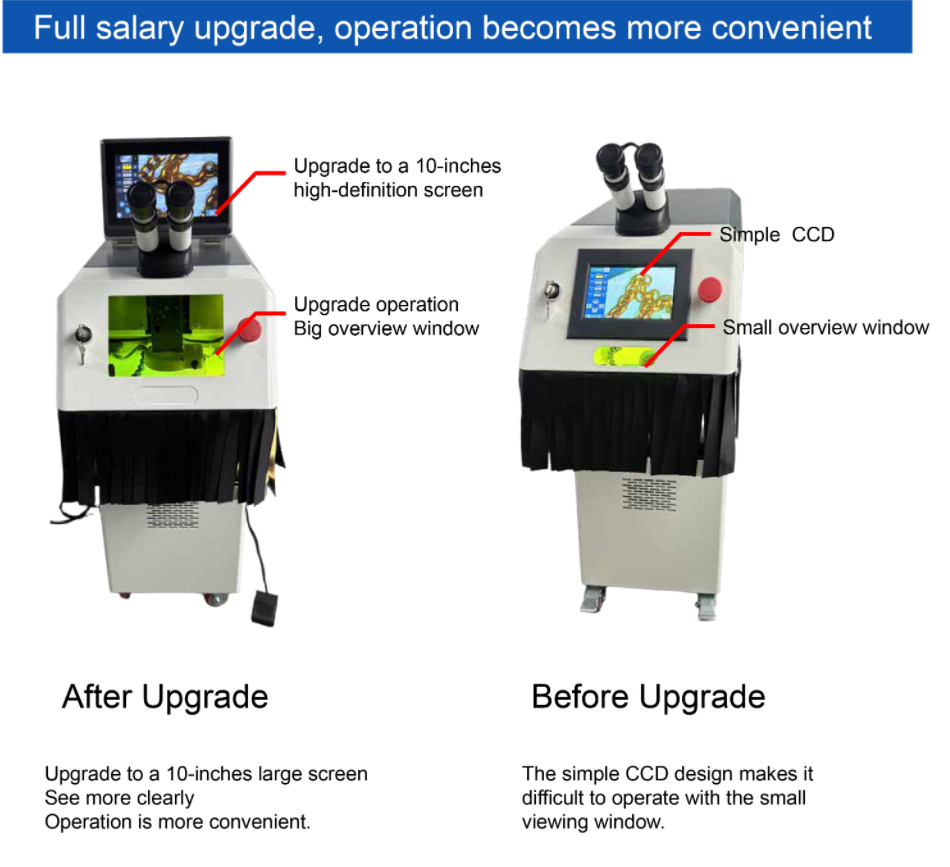

- Easy Operation + High Efficiency: Most models are equipped with jewelry-specific modes (e.g., solid gold joining, claw setting reinforcement, jewelry repair). Beginners can master it after simple training. The single welding time is short (≤0.3 seconds), and the efficiency is increased by 3-5 times compared with manual welding, accommodating both small-batch customization and mass production.

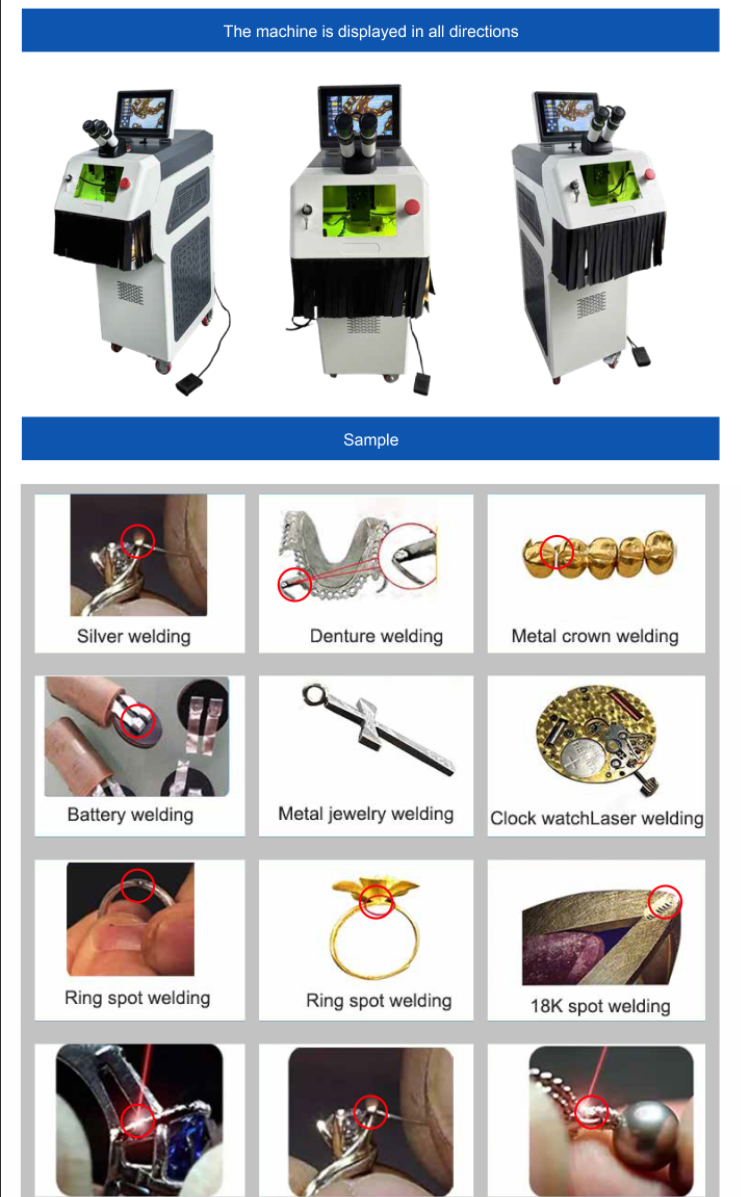

II. Main Application Scenarios

- Jewelry Production: Joining of solid gold jewelry, reinforcement of gemstone claw setting/bezel setting, and structural connection of complex jewelry.

- Jewelry Repair: Repair of broken chain links, clasp replacement, and reinforcement of loose inlaid gemstones.

- Renovation & Transformation: Rewelding and reshaping of old jewelry, and precision touch-up welding of worn parts.

Write your message here and send it to us