In a busy industrial workshop, Engineer Li was facing a tricky problem. A precision mechanical component had stubborn oil stains attached to its surface. These contaminants not only affected the equipment’s performance but also posed potential risks to subsequent production processes. Traditional cleaning methods, such as chemical solvent soaking and mechanical scrubbing, were either inefficient or likely to damage the component surface, leaving Engineer Li frustrated.

By chance, he learned about an innovative technology—laser cleaning—and decided to give it a try. A thin laser beam swept gently across the component surface. Within seconds, those stubborn stains magically disappeared, and the surface regained its original smoothness. This scene amazed Engineer Li and made him deeply appreciate the charm of laser cleaning technology.

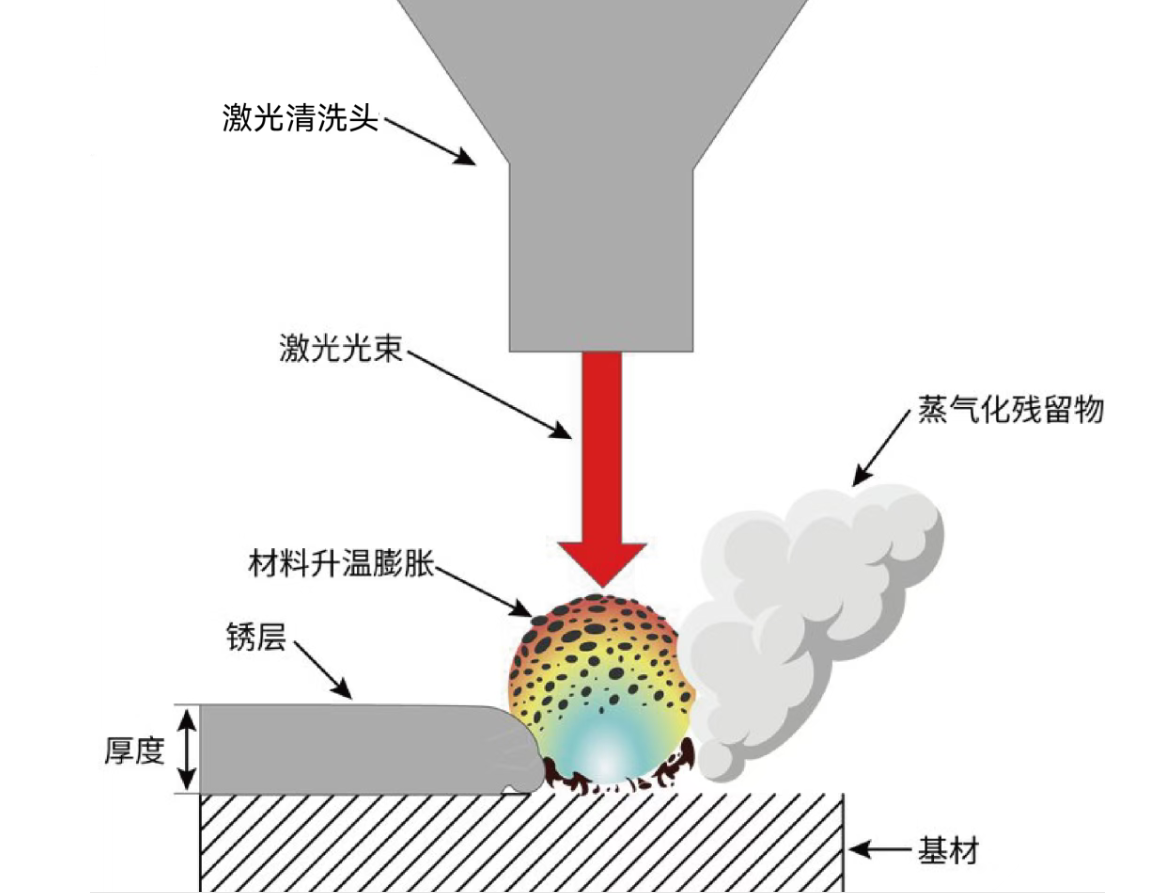

Laser cleaning is an advanced cleaning technology that uses high-energy laser beams to irradiate the object surface. Through optical and thermal effects, impurities, contaminants, or coatings are rapidly vaporized or stripped away.

The core component of laser cleaning equipment is a laser with high pulse energy, high average power, and high peak power. As we all know, laser is a light source with high brightness, high consistency, and high directionality. Pulsed laser can release high-energy laser beams in an extremely short time, featuring high peak power and energy density.

Compared with continuous laser, pulsed laser can generate high temperatures in an instant. However, due to the extremely short duration, heat has no time to conduct to surrounding materials, thus greatly reducing the thermal impact of the laser on the substrate material. When the laser beam irradiates the cleaned surface, the laser energy is absorbed, producing a strong thermal effect on contaminants in a very short time. This thermal effect raises the temperature of the contaminant or coating surface, causing it to vaporize, decompose, or peel off. Meanwhile, the high energy density of pulsed laser allows it to directly penetrate certain materials without easily damaging the substrate surface, making the cleaning process more efficient.

Why Laser Cleaning is the Inevitable Trend

Driven by the global industrialization wave and the in-depth implementation of environmental protection strategies such as “carbon peaking” and “carbon neutrality,” laser cleaning, as a green and efficient cleaning method, is gradually gaining market popularity and becoming a major trend in the global cleaning market development. According to a report by market research firm Mordor Intelligence, the global laser cleaning market size is expected to reach 780 million US dollars in 2024 and grow to 1.53 billion US dollars by 2029, with a compound annual growth rate (CAGR) of 14.61% from 2024 to 2029.

- Non-contact cleaning: Laser cleaning does not require direct contact with the object surface, avoiding damage to the substrate caused by mechanical friction and chemical corrosion, and protecting the integrity and precision of the object.

- High efficiency and precision: Laser beams have high energy density and good directionality, which can quickly heat and remove contaminants, achieving high cleaning efficiency and precise positioning.

- Green and environmentally friendly: The laser cleaning process does not require chemical solvents or large amounts of water resources, reducing environmental pollution and wastewater treatment costs, and complying with the requirements of sustainable development.

- Wide applicability: Laser cleaning can handle the surfaces of objects of various materials and shapes, including metals, non-metals, and complex structural parts, with broad applicability.

- Easy automated integration: Laser cleaning equipment can be easily integrated with automated devices such as robots, realizing automated and intelligent control of the cleaning process.

-

Typical Application Scenarios of Laser Cleaning

Currently, laser cleaning has a wide range of application scenarios in the industrial field. Its characteristics of high efficiency, precision, and environmental friendliness enable it to play an important role in multiple industrial links. Here are several typical application scenarios: -

Surface Treatment

Laser cleaning can efficiently remove oxides, oil stains, welding slag, and other contaminants from metal surfaces, improving surface cleanliness and subsequent processing quality. In mold cleaning, it can quickly remove contaminants on the mold surface, restore the mold to its original state, and avoid loss of mold precision that may be caused by traditional cleaning methods.Automobile Manufacturing

In the automobile manufacturing industry chain, laser cleaning can be used to clean oil stains and impurities on the surfaces of components such as engine blocks, crankshafts, and connecting rods, improving assembly precision and performance. In addition, laser cleaning also plays an important role in local body repair and removal of stubborn stains.Precision Manufacturing

In the semiconductor manufacturing process, laser cleaning can be used to remove micro-particles and contaminants from the surface of wafers, improving product yield and reliability. For precision parts that require high-precision processing, laser cleaning can ensure thorough cleaning of the part surface, meeting strict processing requirements.Cultural Relic Protection

Laser cleaning can be used to remove oxides, dirt, etc., from the surface of metal cultural relics, restoring their original appearance without causing damage. For dirt and mold on the surface of stone cultural relics, laser cleaning can also provide an effective solution.As an advanced light source supplier dedicated to serving precision manufacturing, Guangzhi Technology actively laid out the laser cleaning field as early as 2021 and developed and launched the 100~1000W single-mode and multi-mode GMC Series cleaning lasers. Among them, the single-mode series features high beam quality, stable QCS output, strong cleaning capability, handheld operation, and flexibility. The multi-mode series has a flat-top beam, large output energy, high power, and minimal or even no damage to the substrate. The GMC Series cleaning lasers are suitable for various scenarios such as paint removal, rust removal on metal surfaces, precision mold cleaning, cultural relic protection, high-end machine tools, and track maintenance, meeting the cleaning requirements of different substrates. Currently, they have been applied in multiple industries and gained high recognition from users.

Post time: Nov-07-2025