Advantages of Laser Cleaning Machine Products

—— No damage to the substrate;

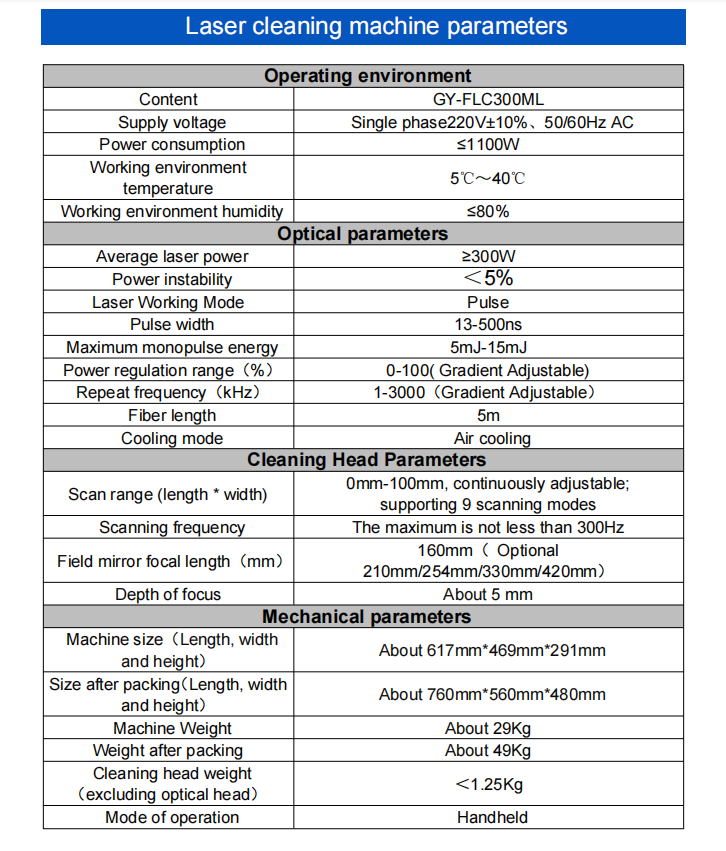

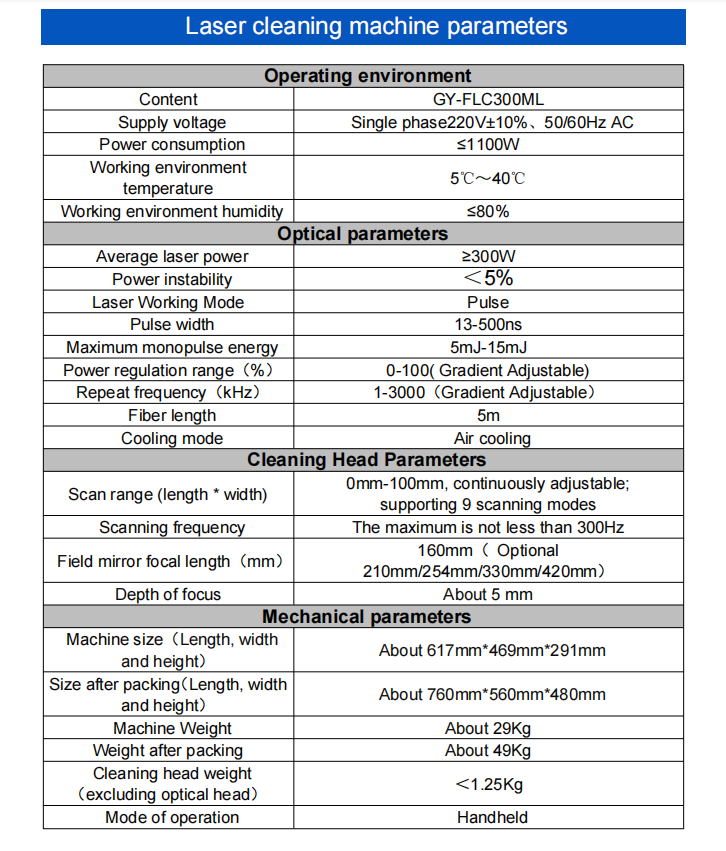

—— Lightweight handheld cleaning head is adopted;

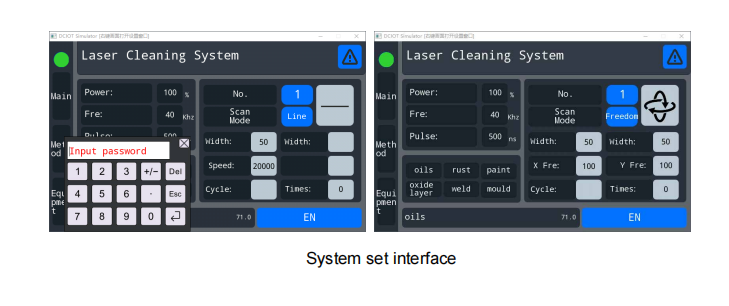

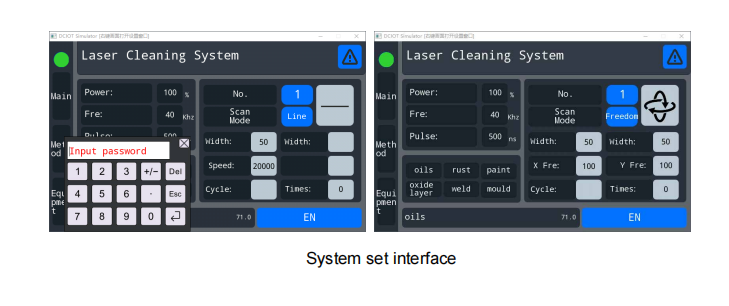

—— Simple operation, can be matched with automated equipment;

—— Integrated structure design of the whole machine;

—— No need to use water or solvents for cleaning;

—— No pollution to the environment, safe and reliable;

—— Wide range of applications, can remove rust spots, oxide scales, dirt and coatings.

Laser Cleaning: A Promising Green Cleaning Technology for the 21st Century Laser cleaning is hailed as one of the most promising green cleaning technologies in the 21st century. Compared with traditional cleaning methods, it boasts distinct advantages such as environmental friendliness, easy automation integration, high efficiency, high precision, and non-contact processing. Additionally, laser cleaning maintains stable costs over the long term, with low operating costs, low maintenance rates, and no additional consumables. It also helps enterprises save certain labor costs; more importantly, it facilitates easy automation implementation.

I. Core Advantages: Why Choose a Laser Cleaning Machine?

Compared with traditional cleaning processes, laser cleaning machines excel in four key dimensions—environmental friendliness, precision, efficiency, and cost-effectiveness—with quantifiable data to help enterprises clearly perceive their value:

1. Zero Environmental Burden, Easy Compliance

No chemical reagents or wastewater discharge are generated throughout the process; only trace amounts of collectible pollutant debris are produced. Emissions of Volatile Organic Compounds (VOCs) are reduced by over 90%, fully complying with the EU REACH Regulation and China’s 14th Five-Year Plan for Energy Conservation and Emission Reduction. According to calculations by an automotive parts factory, after switching to laser cleaning, its annual hazardous waste disposal cost dropped from 150,000 yuan to 12,000 yuan, and investment in environmental protection equipment decreased by 40%.

2. Precision Without Damage, Enhanced Quality

By adjusting laser parameters such as wavelength (355nm ultraviolet/532nm green/1064nm infrared) and pulse width (10ns-10μs), the cleaning range can be precisely controlled, with the heat-affected zone minimized to 5μm. This avoids substrate scratches caused by traditional sandblasting and corrosion from chemical cleaning. Examples include:

- For battery pole pieces cleaned with 355nm UV lasers, residual oil contamination is ≤ 0.1mg/m², and welding strength is increased by 18%;

- For engine crankshafts derusted with 1064nm fiber lasers, the surface roughness is stably maintained at Ra ≤ 1.6μm, and the yield rate of subsequent heat treatment is improved by 20%.

3. High Efficiency & Cost Savings, Short Payback Period

When equipped with six-axis robotic arms and AI visual guidance, laser cleaning machine visual guidance, laser cleaning machines are 3-5 times more efficient than manual polishing. A single device can process 500-1,000 parts per day on average. Although the initial investment is relatively high (500,000-2,000,000 yuan for industrial-grade models), based on a 5-year depreciation period, the cost per cleaning cycle is only 1/6 that of chemical cleaning and 1/3 that of sandblasting. For small-to-medium batch production scenarios, the investment payback period is just 1.5-2 years. After adopting this technology, a new energy vehicle enterprise reduced the cleaning time for motor stators from 12 minutes per unit to 3 minutes per unit, saving 600,000 yuan in annual labor costs.

4. Wide Scene Adaptability, Higher Flexibility

Whether for metals (steel, aluminum, copper), non-metals (carbon fiber, ceramics, plastics), or pollutant types (oil, rust, oxide layers, welding slag, coating residues), precise cleaning can be achieved by adjusting parameters. Unlike traditional processes that require frequent replacement of cleaning media (e.g., special cleaners for aluminum parts), laser cleaning reduces process switching costs by 80%.

Post time:

Sep-19-2025