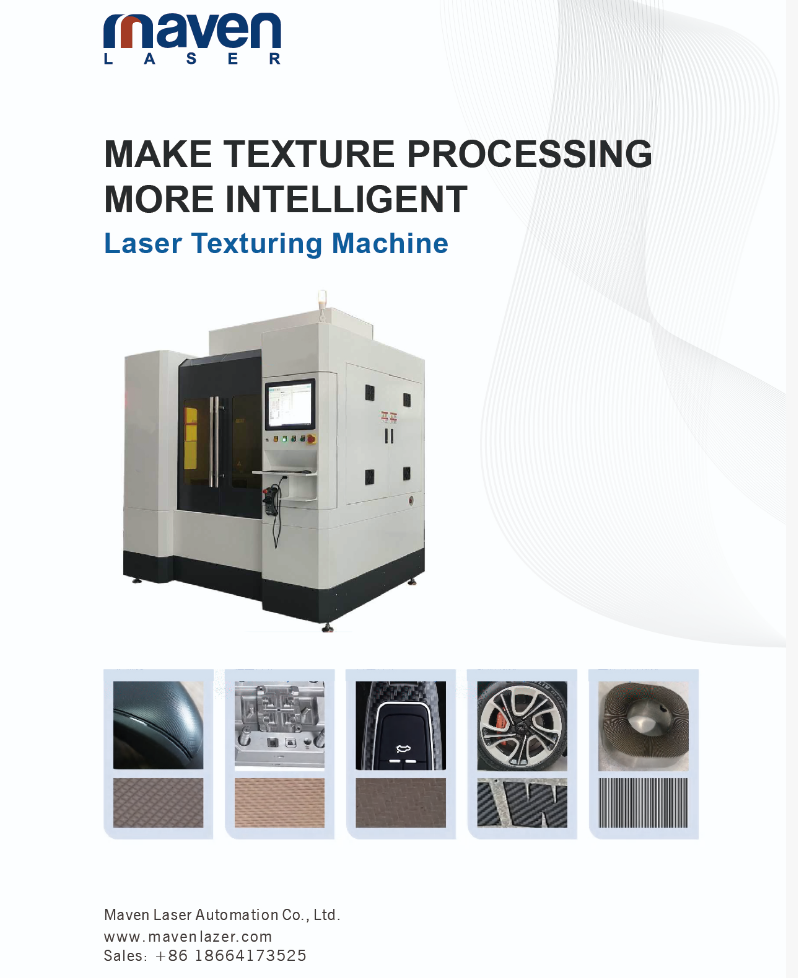

Professional 3D Customization for Consumer Electronics Automotive Field Laser Mold Texturing Marking Machine

The essence of mold texturing lies in "imparting functional and aesthetic properties to products through the transfer of surface textures from molds". Its main functions include:

Aesthetics: Enhancing the surface texture of products (such as simulating leather, wood grain, and metal wire-drawing effects) and concealing injection molding defects (such as shrinkage marks and weld lines);

Functionality: Increasing the surface friction of products (such as anti-slip textures on mobile phone middle frames and textures on automotive interior buttons), or optimizing optical effects (such as diffusing textures on lampshades);

Identifiability: Creating hidden logos, production dates, or anti-slip warning textures (such as textures on tool handles).