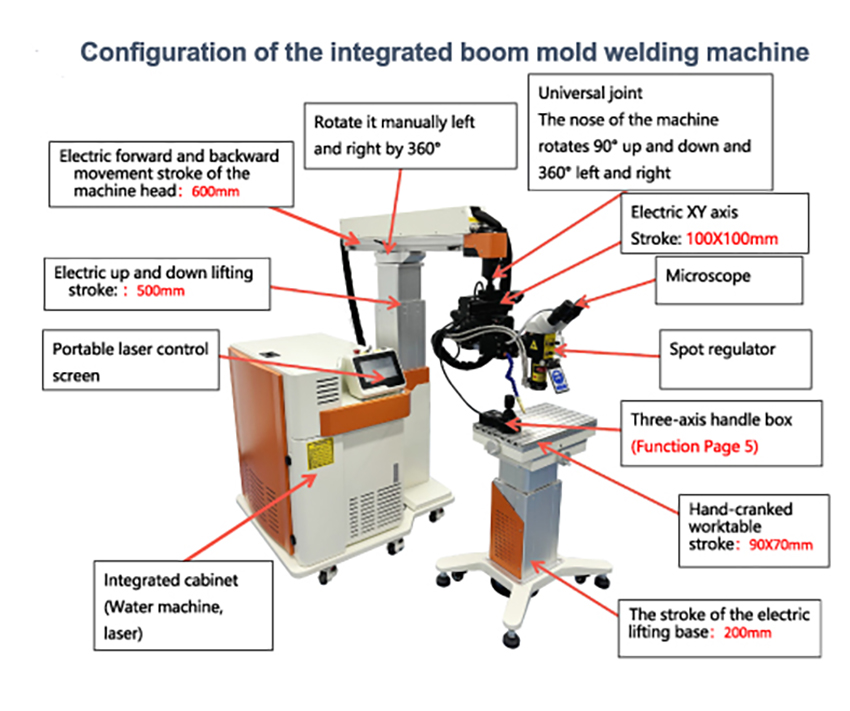

New Air-Cooled System CCD Positioning Auto-Focus 200W Jewelry Electronic Mold Repair Precision YAG Fiber Laser Mold Welding

Core Functions and Advantages

Precise repair without damaging the base material: Adopting point-to-point pulse welding technology, the welding points are concentrated with a small heat-affected zone, avoiding deformation, annealing, or cracking of the mold base material.

Compatible with various mold materials: Capable of welding common mold materials such as mold steel, stainless steel, alloy steel, and copper alloy, meeting repair needs of different molds.

Flexible operation for complex scenarios: Compact and portable in design, paired with small-diameter welding materials, it can reach narrow areas like mold cavities and corners for welding. It can also be used for mold surface strengthening (e.g., improving wear resistance and corrosion resistance).

Stable welding quality: Weld points are firm and dense. The mold surface remains flat after repair, requiring minimal subsequent grinding and polishing, without affecting mold precision.

Application Scenarios

Repair of mold production defects: Patching flaws such as edge chipping, scratches, and pinholes during the processing of new molds.

Mold maintenance and renovation: Repairing wear, cracks, gate sticking, and other issues of used old molds to extend their service life.

Mold surface strengthening: Welding wear-resistant alloy layers on easily worn parts of molds (e.g., cavities, guide pillars) to enhance performance.

Customization for special needs: Precisely filling tiny defects (above 0.1mm) of precision molds to ensure mold forming accuracy.

Write your message here and send it to us