New Technology for Mold

-

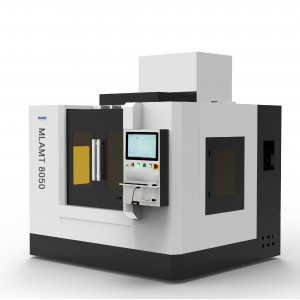

Laser mold texturing system

— High precision control, small subdivision angle, and fine texture;

— Automatic compensation, high drop machining;

— Large format texture consistency, seamless splicing;

— Smooth operation of image files within 200G;

— Supports importing STP, STL, OBJ, IGS, PLY, vector images, bitmaps, and grayscale images;

— Configure optical instruments, mold positioning does not require manual repeated adjustments;

— Easy to operate, flexible and easy to understand. -

Special machine laser cladding quenching equipment

1. The laser cladding layer and the surface of the workpiece form a solidmetallurgical bonding interface.

2. The laser energy control is concentrat.ed, and the heat input causes minimal deformation of the workpiece.

3.Greatly improve the wear resistance, corrosion resistance and oxidationresistance of the parts surface.

4.Recycling and remanufacturing prolongs the service life of equipmentand saves usage costs.

-

Maven Laser Texturing machine on Automobile Tyre mold

Laser texturing technology has brought an innovative revolution to moldsurface processing! From digital computer design to generation program,the fidelity of any graphic texture can be guaranteed by laser processing(the finest can reach 3um).With laser Technology used for ultra-fine pro-cessing to make the texture design more variety and achievable.Laser Texturing is enlarging your design imagination come true to theproducts!Laser mold texturing system advantage—— High precision control with fine subdivision angles for delicate patterns—— Automat ic compensation for high drop processing—— Consistent large-area texture with seamless splicing—— Smooth operation of files within 200G—— Support various formats such as STP, STL, OBJ, IGS, PLY, TlFand bitmaps—— Equipped with optical instruments for mold positioning without manual ad justment—— Easy to operate,flexible and easy to understand—— Gaochuang Servo from Israel, THK slide rails from Japan, and IPG laser from Germany produced by RaylaseLaser mold texturing system Application Fields

—— 3C Sector

—— Mold industry

—— Automotive Industry

—— Tire industry

—— Other Specialized FieldsTexture Effects -

Industrial Cobot QCW Mold Repair Fiber Welding Machine

▶Automatically find focus

▶Multiple cleaning modes

▶The cleaning head can be operated on the touch screen

▶Equipped with air knife and protective lens function

▶The cleaning head can be held by a handheld and hanging robotic arm, as well as a collaborative robotic arm

-

Precision Mold Repair Mold Laser Welding Machine

Cantilever fiber mold laser welding machine is a new type of welding processing, mainly for thin-walled material precision parts welding, can realize butt welding, sealing welding, spot welding, stack welding, etc., small welding seam width, high depth to width ratio, small heat affected zone, small deformation, fast welding speed, smooth and beautiful welding seam, no treatment or only simple treatment after welding, high quality welding seam, no porosity, precise control of positioning accuracy, small focusing spot, easy to realize welding automation.

-

Industrial Cobot Laser Cleaning Machine

▶Automatically find focus

▶Multiple cleaning modes

▶The cleaning head can be operated on the touch screen

▶Equipped with air knife and protective lens function

▶The cleaning head can be held by a handheld and hanging robotic arm, as well as a collaborative robotic arm