Automatic High Accuracy Anti-Collision for Electronic Manufacturing Medical Automotive Parts Cobot Laser Welding Machine

Cobot MIG Welding Machine: Precision Meets Safety

The Cobot MIG Welding Machine is a advanced collaborative robot designed for metalworking and arc welding applications.

Unlike traditional industrial robots, this collaborative welding robot operates safely alongside human workers, enhancing productivity without compromising safety.

Equipped with argon arc welding and X-ray Arc Welding capabilities, it ensures high-quality welds in shipbuilding, fabrication, and hardware parts production.

Hardware parts robot laser welding machine advantages:

Collaborative Design: Safe for human interaction, reducing workspace barriers.

Versatility: Supports MIG, CO2, and laser welding, including aluminum cobot welding and frame cobot welding.

Precision: Delivers consistent welds for metal process and mold cobot laser cleaning tasks.

Mobility: Available as a mobile cobot MIG CO2 welding unit for flexible deployment.

Applications: Ideal for shipbuilding welding robot machines, automatic welding robots, and fabricator automatic welding robots. Perfect for industries requiring cobot MIG welding station accessories and bottom fly MIG welding machines.

Elevate your metalworking with this magmeet cobot welding machine—efficient, safe, and future-ready.

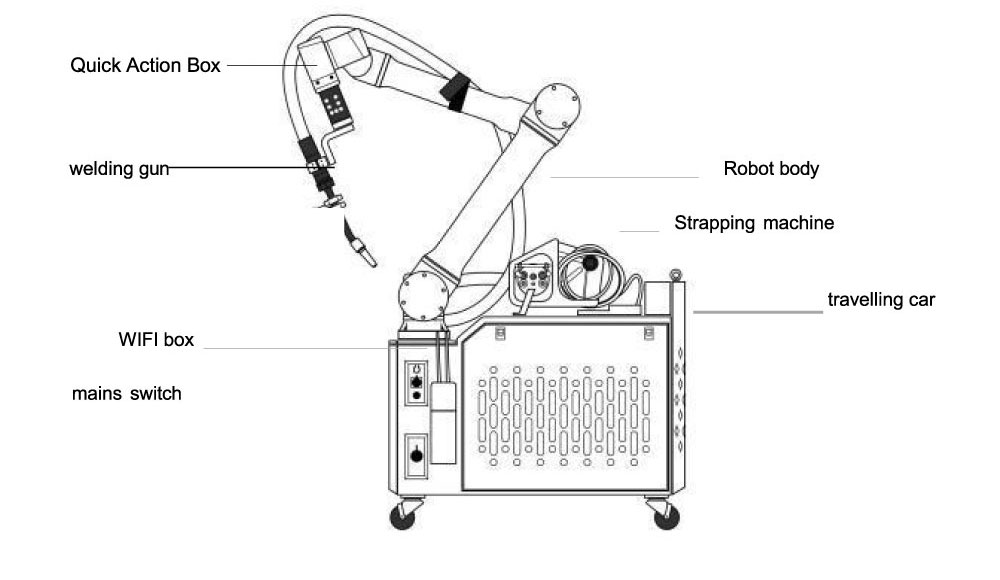

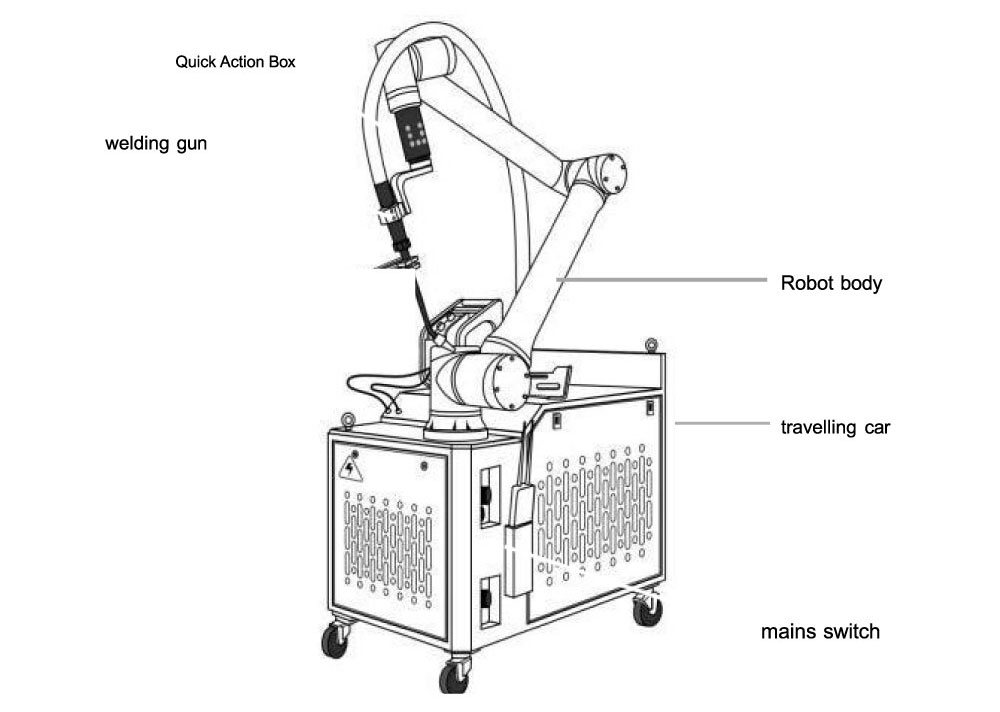

Cobot mig Welding Machine Standard configuration

Robot body, trolley, MIG500 welding power supply, water-cooled welding gun, human-computer interaction tablet computer, push-button handle.

Optional accessories

Cooling water tank, magnet, external shaft nine-axis, laser positioning tracking, arc tracking, Internet of Things.

Technical Specifications

*Robot Body*

Six-axis collaborative robot

Load capacity: 9 Kg

Robot repeatability positioning accuracy: ±0.05mm

Maximum working range (radius): 1500mm

Body weight: 68 Kg

*Robot Controller*

Maven laser

*Human-Computer Interaction System*

Equipped with wired connection, optional wireless connection

*Welding Power Supply*

350PLUSEA/500PLUSEA options available

Standard feature: water cooling

*Portable mobile vehicle (optional)*

Dimensions: 1200*700*1000mm

Model A: Simple style. Lightweight and easy to move, clear at a glance

Model B: Complete package style. Fashionable appearance, comprehensive protection

Core Features

- Safe Collaboration

- Flexible Adaptability

- Ease of Use and Deployment

- Stability and Economy

Applications of Collaborative Robots

- Electronic Manufacturing: Assembly of mobile phone/computer components (e.g., screen lamination, battery installation), auxiliary positioning for laser marking of PCB boards, sorting and arranging of electronic components.

- Automotive and Auto Parts: Screw fastening for car seats, assembly of dashboard parts, loading and unloading of small castings (replacing manual handling).

- 3C Home Appliances: Handling of washing machine/refrigerator casings, assembly of home appliance buttons, auxiliary for laser engraving of product serial numbers.

- Medical Equipment: Sorting and packaging of medical consumables (e.g., syringes, masks), organizing of surgical instruments after disinfection, transfer of laboratory samples.

- Food Processing: Grasping of dough in the baking industry, sorting in the fresh food industry (e.g., fruit grading), packing of food in the packaging process (avoiding contamination from manual contact).

1.Small-sized, ligh tweight design, light weight and flexible;

2. Can be freely dragged and dropped, with high flexibility;

3. The welding functions include: straight line welding, arc welding, intermittent welding and external shaft matching;

4. Equipped with a tablet computer, it is shock-proof, water-resistant and fire-resistant, and allows for visual parameter settings;

5. The Maven automated control system is easy to operate and provides precise welding.

6. External WiFi device.

7. Configure the quick handle, and the operation is simple and convenient.

8. The robotic arm can adjust its posture within a 360-degree range.

COBOT ROBOT MIG WELDING APPLICATIONS

Typical application scenarios:

- Automobile manufacturing: Body panel spot welding (daily production capacity of 5,000 weld points per machine)

- Construction machinery: Long straight weld seams and spatial curve welding

- New energy sector: Precise welding of lithium battery shells

Medical devices (surgical instruments, disinfection equipment)

Chemical industry storage tanks, pipelines

Hydrogen energy storage gas cylinders in the new energy field

Aluminum alloy frames of aircraft fuselages

Heat-resistant alloy components of engines

In the aerospace and rail transportation fields. Such as welding of aluminum alloy frames for high-speed train carriages

Welding of heat-resistant steel and low-temperature steel for oil pipelines and power station boilers

When cracks or wear occur in plastic molds and stamping molds, arc welding can be used for local repair

In the fields of automobiles and components, 3C and semiconductors, metal and plastic processing, scientific research and education, commercial services, medical care, etc., it can increase the output and quality of various industries, achieve flexible production, and improve employee safety.