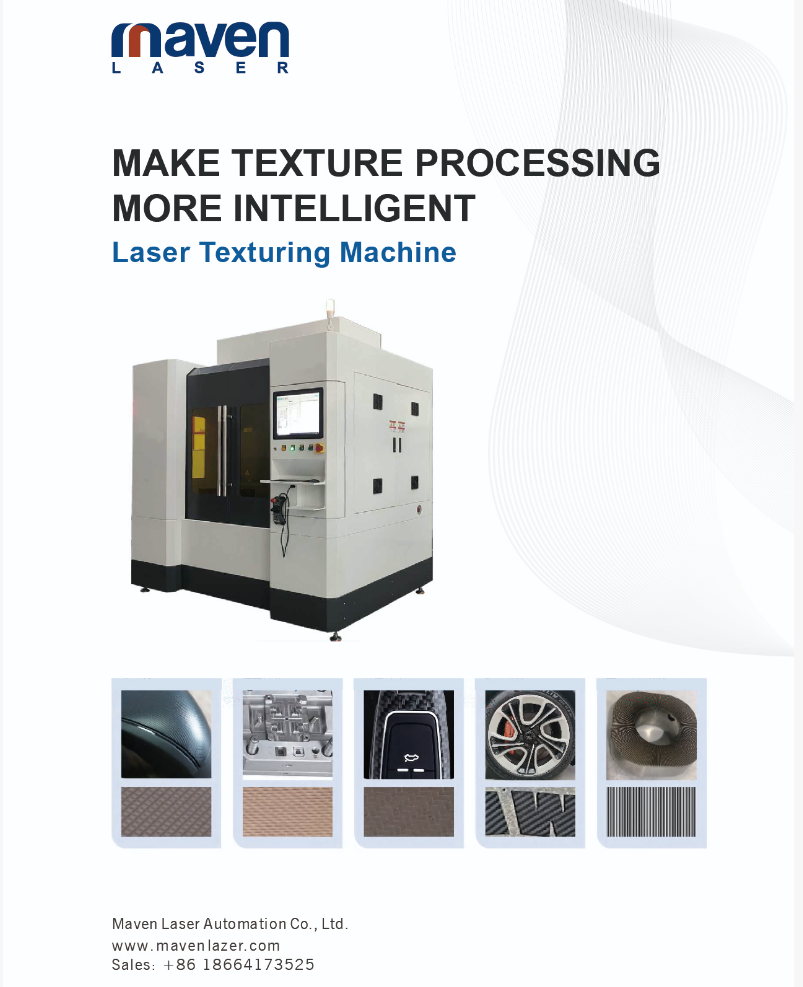

China Maven Automatic for Mold Factory 3D Mold Texturing Laser Marking Machine

Core Functions

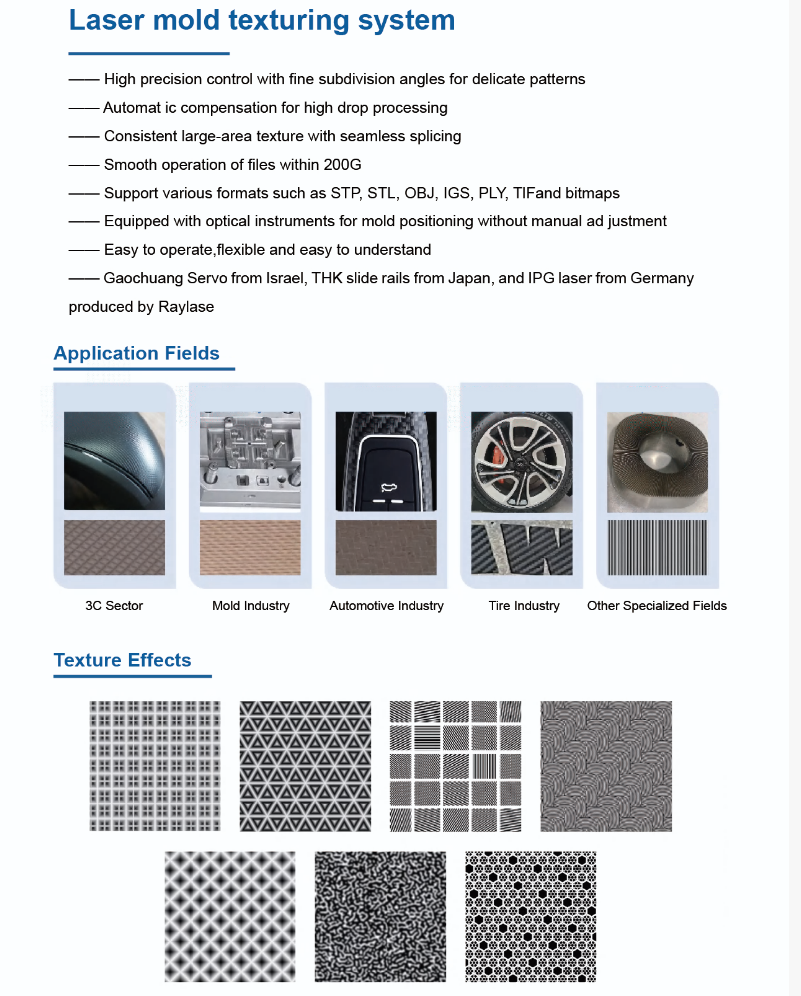

- Enhancing Visual Hierarchy

(Refers to simulating the texture of natural materials through different patterns to add layering to the product surface, avoiding a monotonous and cheap appearance of smooth surfaces.) - Concealing Surface Defects

(Helps weaken minor flaws on the finished product surface, such as shrinkage marks, weld lines, or tiny scratches, thereby reducing the defect rate.) - Unifying Visual Standards

(Ensures consistent surface textures of products produced by different molds in the same batch through standardized texturing processes, eliminating individual differences from manual processes.) - Anti-slip and Grip Improvement

(Increases surface friction through texture, enhancing safety during use, e.g., on tool handles or car steering wheels.) - Anti-reflection and Tactile Adjustment

(Matte textures reduce light reflection to avoid glare, while the concave-convex structure of patterns creates differentiated tactile sensations like “smoothness” or “granularity”.) - Assisting Molding and Demolding

(Special textures help discharge air from the mold cavity during injection molding to prevent bubbles; slight textures also reduce the contact area between the finished product and the mold for easier demolding.)

Write your message here and send it to us