Yag Spot Jewelry Laser Welding Machine

Yag Laser Jewelry Laser Welding Machine

FEATURES

— Gold and silver repair welding without painting

— Maximum 230W,90Joule

— 50% energy saving

— High resolution vision CCD,7inches

— 24 hours contentiously working

Good safety: with high-speed electronic light filter protection device to protect the operator's eyes from laser damage, relieve the operator's eye fatigue and improve work efficiency.

Strong anti-interference ability: the use of advanced new technology micro industrial control computer, instead of the full functionality of ordinary computers, its operability and stability to a higher level, and keep pace with the times.

High stability: the use of double closed-loop precision control, to ensure that the energy of each welding point is uniform and consistent.

Simple and convenient operation: with a large screen high-definition CCD vision, the English interface parameter settings are simple to understand, can save multiple parameters to facilitate continuous work.

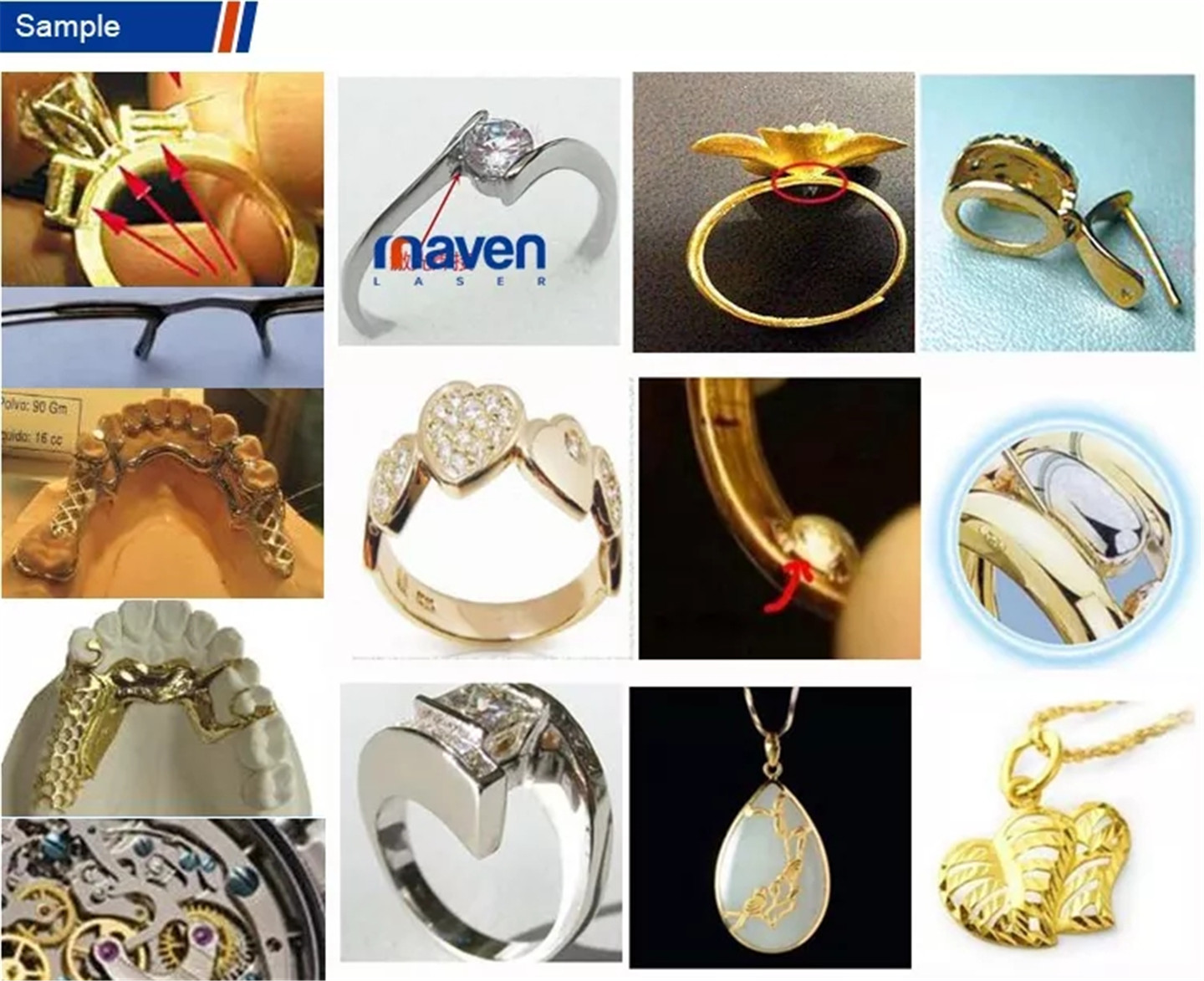

Laser spot welder is mainly use in jewelry and dental industry or other hardware field. This kind of machine can process all metallic material, which used for making jewelries such as gold, silver, platinum, titanium, palladium,K-Gold,Stainless steel, and their alloys. It is mainly used for manufacturing and repairing jewelries, as well as precisely welding a variety of micro and heat- sensitive parts, just like nickel straps of batteries, hairsprings, watch components, down-leads of chips.

Product Advantages

Overall CCD jewelry laser welding machine

2. Focus spot adjust part

3. Preset laser welding parameters. Including gold, silver, steel, titanium and custom.

4. Status reference bar

5. Power, pulse width and frequency adjust part

6. Setting

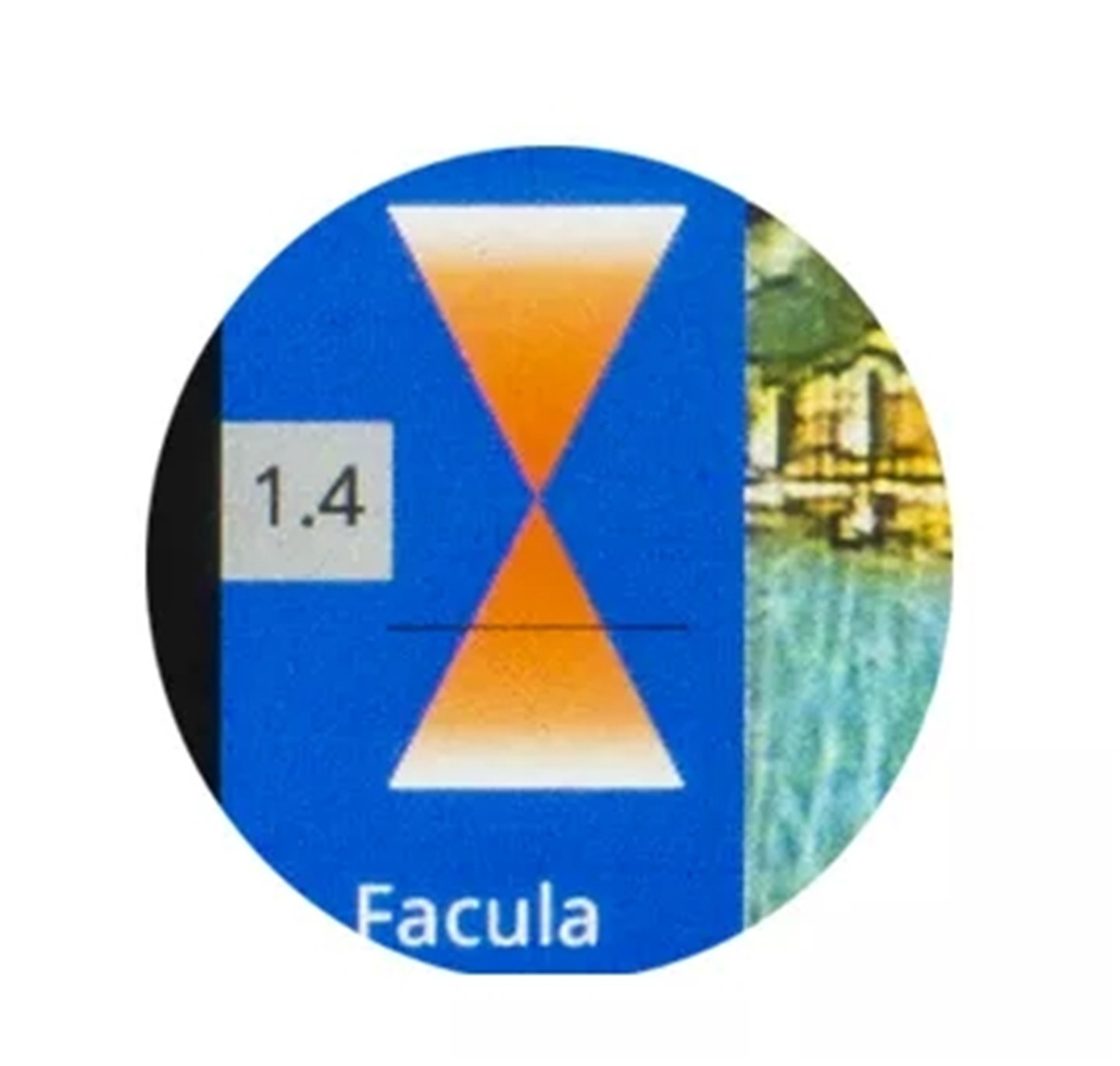

Spot size adjustment

User-friendly adjustment settings, ranging from -3.0mm to 3mm.

Spot size at minus direction, it is more suitable for leveling post treatment welding and thin gold and silver sheet laser repairing welding.

While at plus direction, more suitable for deep spot laser welding

Focus cross line adjust center

Position of focus cross line can be easily adjusted through this part

Preset parameter and adjusting

Prest laser welding paramter is our suggest one, including K-Gold/Pt/Ti, silver, steel, copper and custom.

Laser power: 0.1%~100%

Pulse width: 0.1ms~20ms

Frequency: 1Hz~50Hz

Patent beam path

Patent beam path and whole machine stucture design make Mavenlaser company's jewellery laser welding machine outstanding and perfect, neither on performance or in size.

Laser welding chamber

1. Air nozzle

2. Emergency button

3. High quality yellow lighter

4. High quality White lighter

5. Spot manual correct motor wheel

6. Joystick

| Item |

Power (%) |

Pulse width(ms) |

Frequency(Hz) |

Painting |

| Steel |

17.5% |

1.0ms |

5Hz |

No need |

| K-Gold/Pt/Ti |

35.2% |

1.5ms |

5Hz |

No need |

| Copper |

41.1% |

2.0ms |

4Hz |

No need |

| Silver |

60% |

1.0ms |

2.9Hz |

No need |

| Custom |

/ |

/ |

/ |

/ |

Specification

| Product name | Jewelry laser welding machine |

| Laser source | Nd: YAG 1064nm |

| Model No. | MLA-W-A01 |

| Max laser power | 230W |

| Frequency range | 1~50Hz |

| Pulse width range | 1~20ms |

| Spot size range | -3mm~3mm |

| Power impulse and time | 140J @20ms |

| Aiming positioning | CCD, 10X microscope |

| Positioning accuracy | +/-0.02mm |

| Input voltage | 220V 50/60Hz 30A |

| Machine size | 790*390*1090mm |

Sample & Application